Multi-Sided Component Cooling

Discover how pressed-in tubes on at least two sides of the four-sided base body ensure optimal heat transfer – without any foreign media, purely through our pressing technology.

We rely on proven joining methods such as pressing, soldering, bonding, and welding. Our experts provide personalized advice to develop the optimal cooling solution – perfectly matched to your requirements.

Pressing technologies are key in the production of efficient heat sinks and liquid cooling plates for power electronics. They combine force-fit and form-fit connections to create high-performance cooling structures and optimally integrate complex cooling circuits.

Learn more

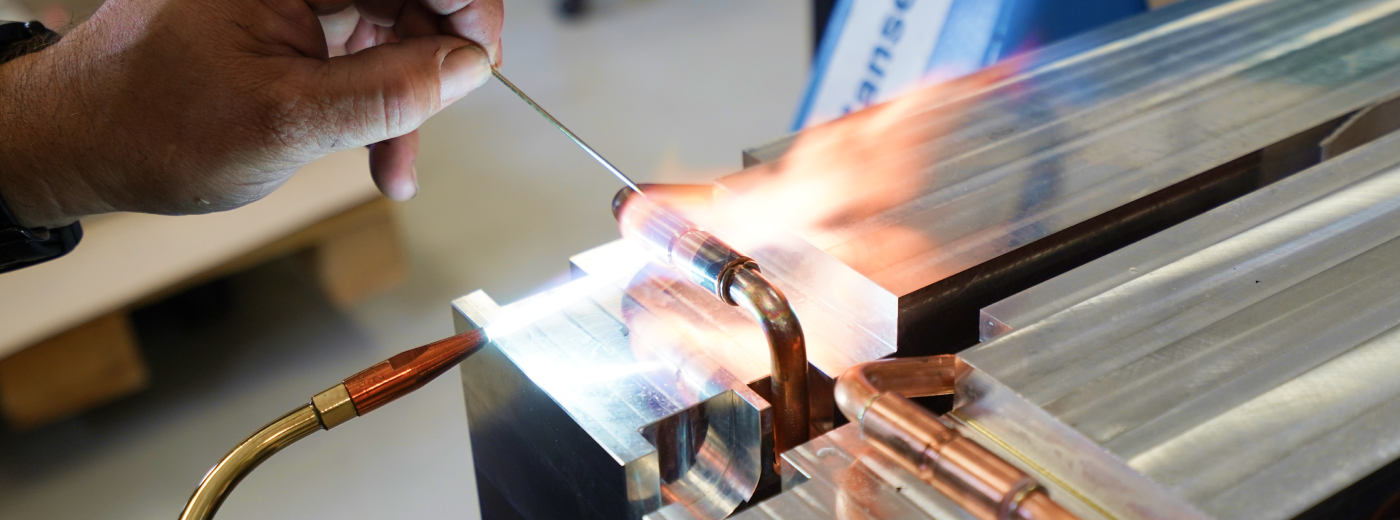

Soldering uses precise brazing or flexible soft-soldering methods. These techniques enable accurate component integration and ensure efficient heat dissipation in heat sinks and liquid cooling plates.

Learn more

Welding reliably joins different materials. Modern welding techniques ensure high strength, tightness, and thermal conductivity, maximizing the performance of cooling structures.

Learn more

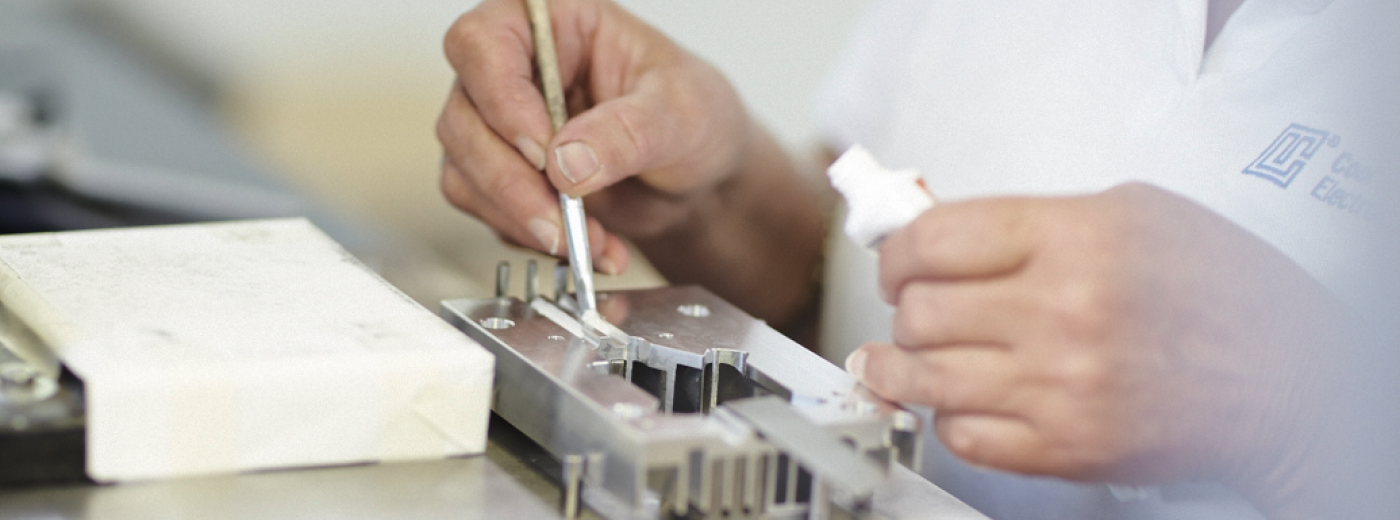

Bonding technologies are becoming increasingly important in the manufacturing of heat sinks and liquid cooling plates. They enable efficient joining of materials such as aluminum, copper, and composites – often as a flexible alternative to welding and soldering.

Learn moreOur team of experts provides fast, practical, and personalized advice – for precise joints, efficient heat dissipation, and durable results.

Learn how to optimize cooling for high-tech applications – with solutions that are efficient, reliable, and ready to implement.

Download report