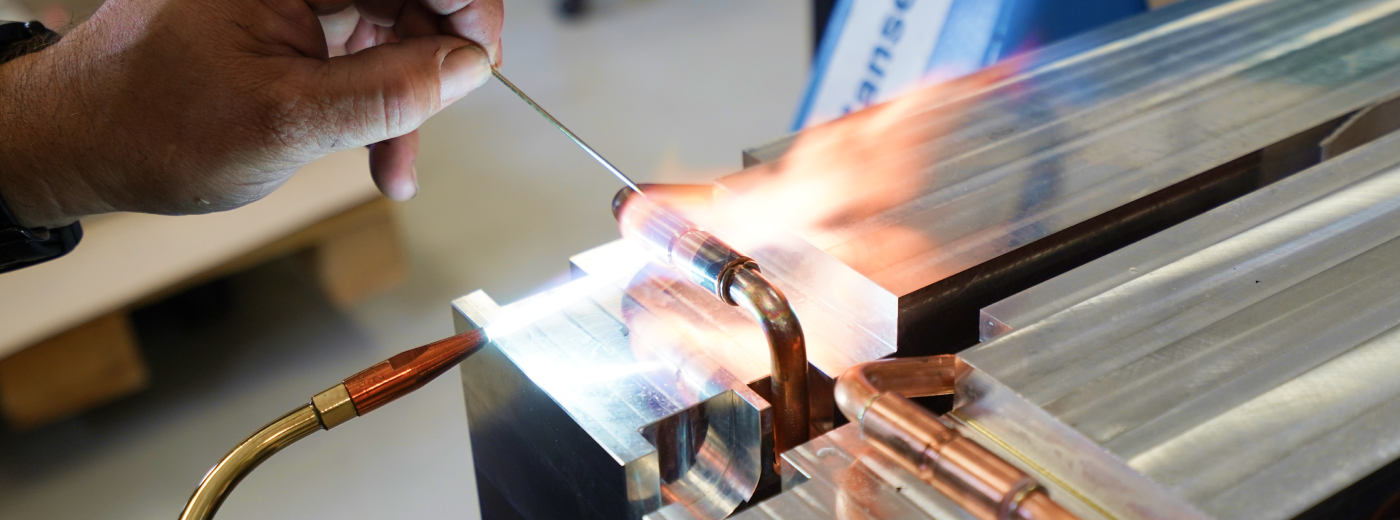

Soldering

Learn how modern soldering techniques create perfect joints – ensuring maximum tightness, thermal conductivity, and durable cooling structures.

Press technologies play a central role in manufacturing high-performance heat sinks and liquid cooling plates in modern power electronics. By combining force-fit and form-fit connections, copper or aluminum tubes are precisely pressed into the cooling structures. This creates a direct metallic bond that is both thermally efficient and mechanically robust. The technique enables compact, durable, and high-performance cooling solutions without the need for additional sealing materials or connecting elements.

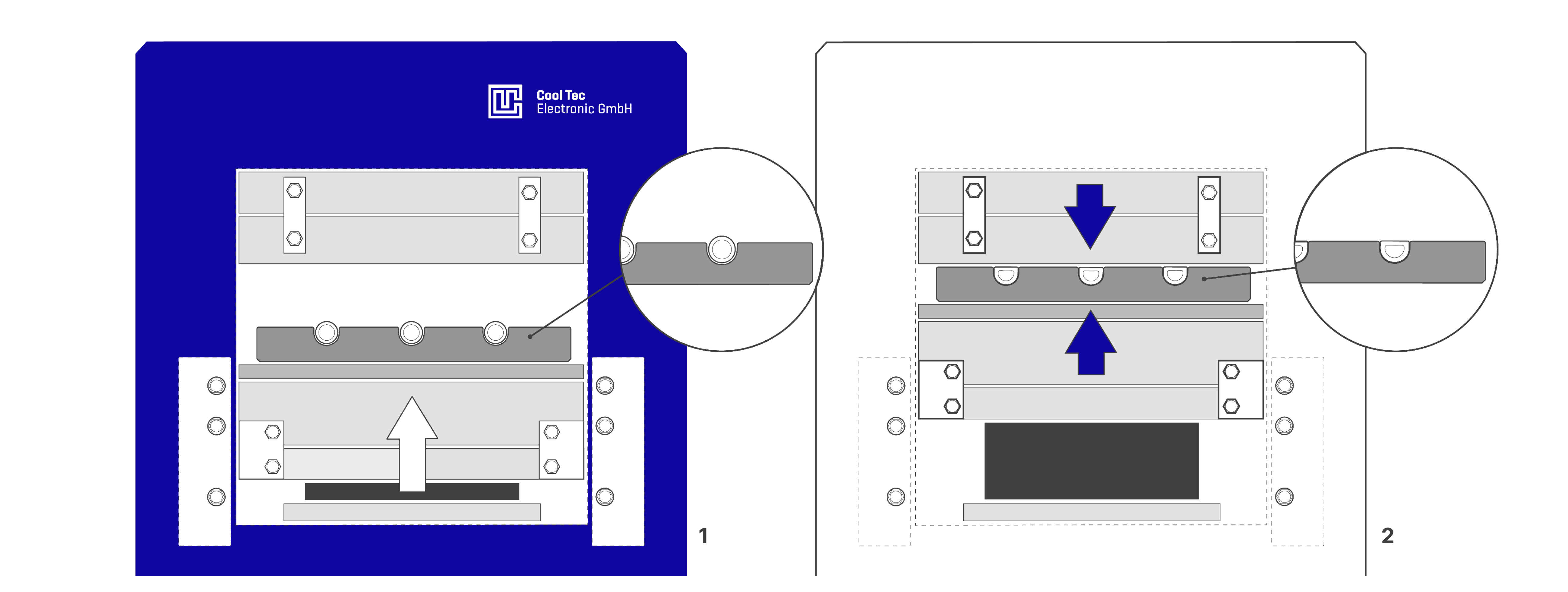

Learn more in a conversationThe pressing process, also known as Tube Expansion or Roll Bonding, involves several steps:

Specially milled grooves are precisely matched to the tube geometries to ensure a secure anchoring of the tubes.

Copper or aluminum tubes are pressed into the prepared grooves. Through the combined force-fit and form-fit connection, a permanent and mechanically durable bond is created.

The direct metallic contact between tube and heat sink ensures excellent heat dissipation. At the same time, the process allows the integration of various tube lengths, diameters, and geometries – ideal for high-performance applications, prototypes, or small series.

Copper tubes provide particularly effective heat dissipation thanks to their high thermal conductivity, while aluminum tubes are ideal for space- or weight-sensitive applications due to their low weight and corrosion resistance. The choice of material depends on specific requirements such as desired heat conductivity, corrosion protection, or weight.

Press-fitting also offers high production flexibility: different tube lengths, diameters, and geometries can easily be adapted and integrated into the cooling plates. This enables liquid cooling plates to be tailored to varying performance requirements and spatial constraints. This flexibility is especially advantageous for prototypes, small batches, or custom solutions where quick adaptations are required.

Excellent thermal conductivity: Metallic bond between tube and heat sink optimizes heat transfer

High mechanical stability: Reliable under thermal and mechanical loads

Process reliability & repeatability: Consistently high quality even for small series and prototypes

Flexible tube integration: Adaptable to various tube geometries, lengths, and diameters

Efficient & economical production: High thermal performance with cost-efficient manufacturing

Overall, press technology enables powerful, flexible, and cost-effective production of liquid cooling plates that perfectly meet the demands of modern power electronics.

Learn more in a conversationWith COOLTEC cooling solutions, you benefit from even heat distribution, reduced hotspots, and extended component lifespan.

In a force-fit connection, the mechanical bond is created through applied pressure. The tube is firmly anchored in the cooling plate, ensuring stability and load resistance.

A form-fit connection refers to the precise matching of component shapes. It ensures optimal sealing, mechanical stability, and a durable connection between tube and heat sink.

By combining force-fit and form-fit principles, a metallic bond is created that is both thermally efficient and mechanically extremely durable – ideal for high-performance power electronics.

Tube Expansion is a process in which tubes are pressed into pre-machined cooling plates. The tube is expanded under pressure to match the cooling structure, forming a direct metallic connection.

Roll Bonding is a process in which two metal plates are bonded together under pressure. In cooling plates, it is used to securely and efficiently integrate tubes or channels into the structure.