Pressing

Learn how modern pressing technologies enable highly efficient heat sinks for electronics and liquid cooling – precise, efficient, and application-optimized.

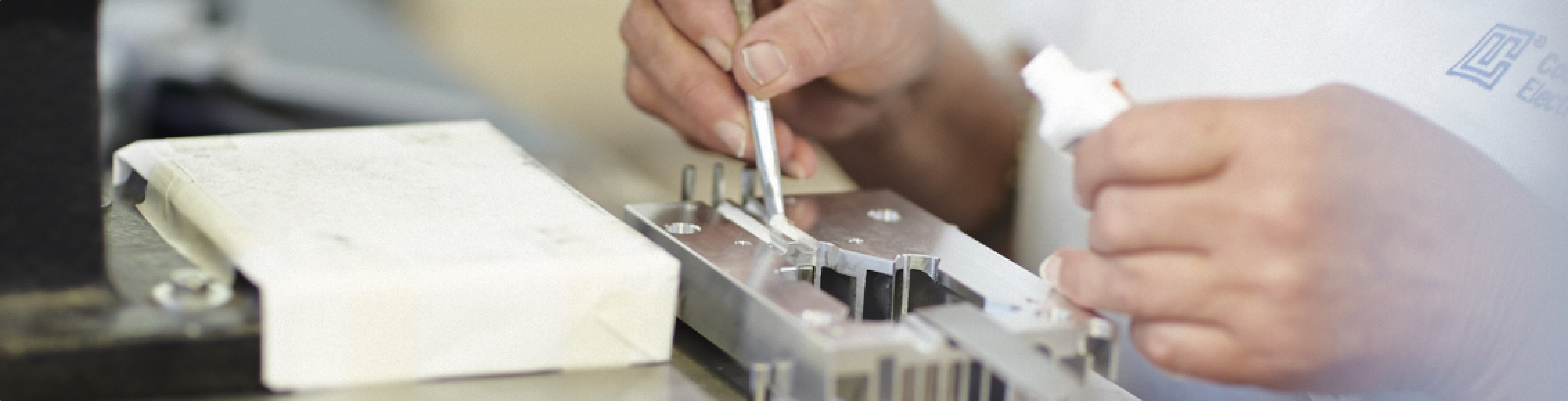

Adhesive technologies enable the reliable joining of materials such as aluminum, copper, and composites without high temperatures or metallurgical changes. They offer efficient heat conduction, mechanical stability, and long-lasting tightness, even with complex geometries and sensitive components.

Learn more in a conversationAdhesive technologies distribute stress evenly, minimizing cracks, deformation, and material fatigue. This is particularly important for liquid coolers and cooling plates.

Bonding allows the joining of materials with different coefficients of thermal expansion, such as aluminum and copper, and compensates for these differences flexibly. The technology is therefore ideal for high-performance applications in power electronics, automotive, and industrial electronics. Sensitive electronic components or sensors can also be integrated, as adhesives cure without high temperatures. This prevents metallurgical changes and protects the components.

Large and complex surfaces can be bonded uniformly, improving heat transfer between components. Specially developed thermally conductive adhesives optimize the thermal flow and increase heat dissipation efficiency – crucial for high-performance applications such as LED heat sinks, inverters, or power electronic modules.

Excellent sealing function: Prevents penetration of liquids or contaminants

Easy automation: Uniform, reproducible application

High design flexibility: Complex, delicate structures without mechanical fastening

Thermal and mechanical integrity preserved: No deformation or melting

Environmentally friendly: Low temperatures, no harmful emissions

Efficient & cost-effective: Especially for series production

Modern, solvent-free adhesives meet strict environmental standards. Combined with the secure joining of aluminum, copper, and composites, bonding represents a forward-looking, flexible, and efficient technology for the production of modern heat sinks and liquid cooling plates.

Sustainability at COOLTECWith COOLTEC cooling solutions, you benefit from uniform heat distribution, reduced hotspots, and longer component lifespan.