Power Supply

Learn how optimized cooling technology ensures the reliability of power supply components, transformers, and converters.

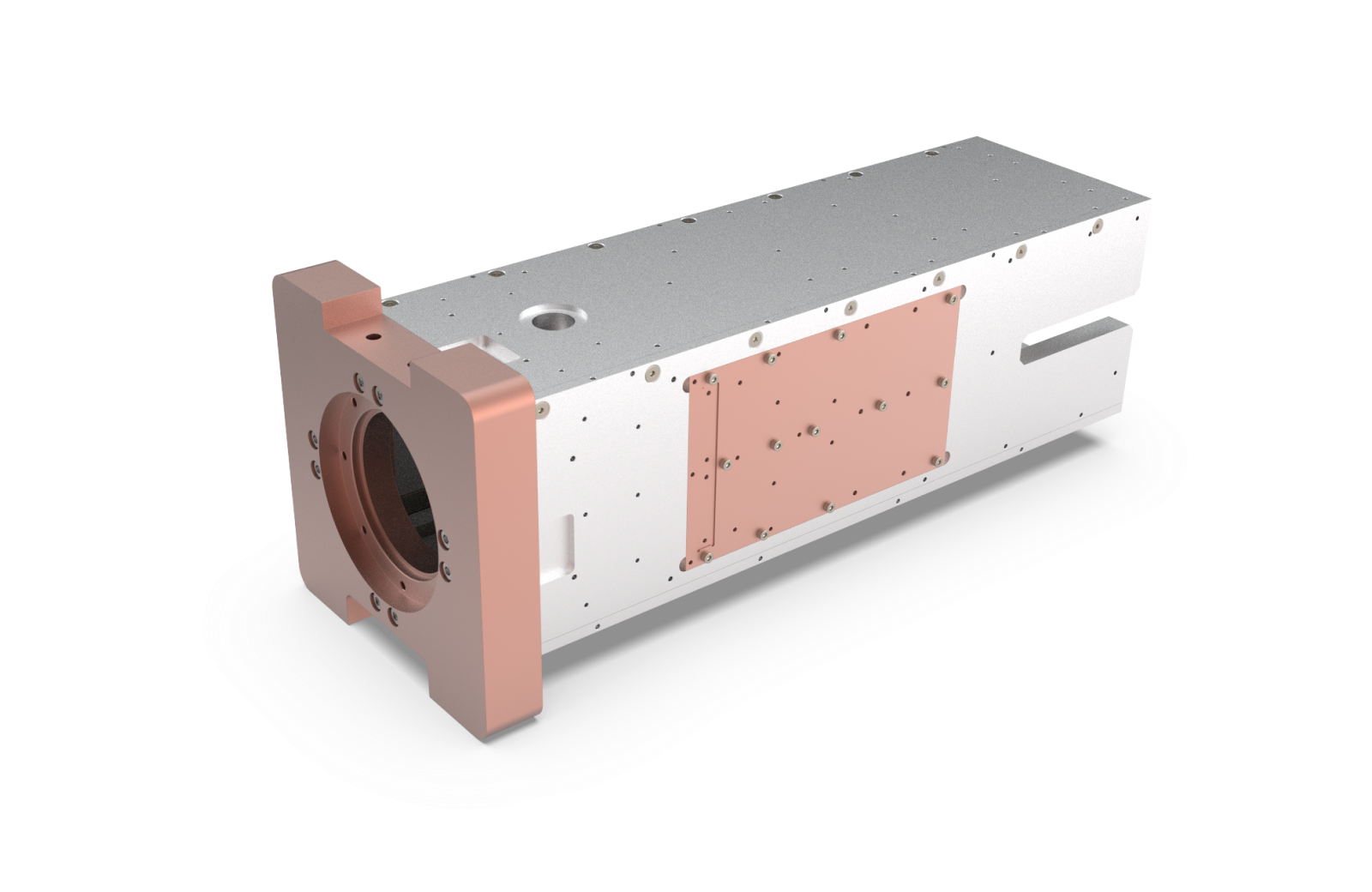

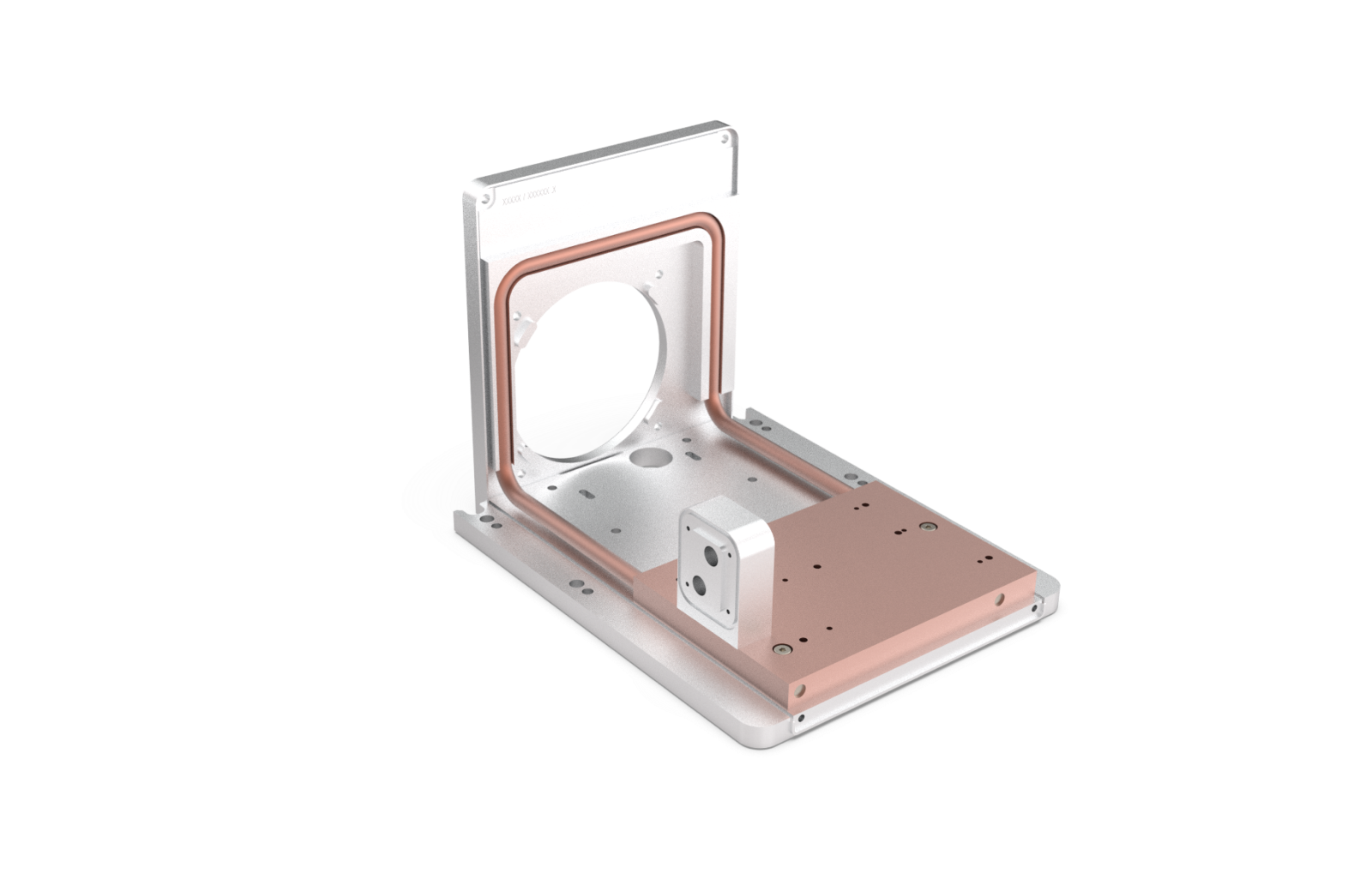

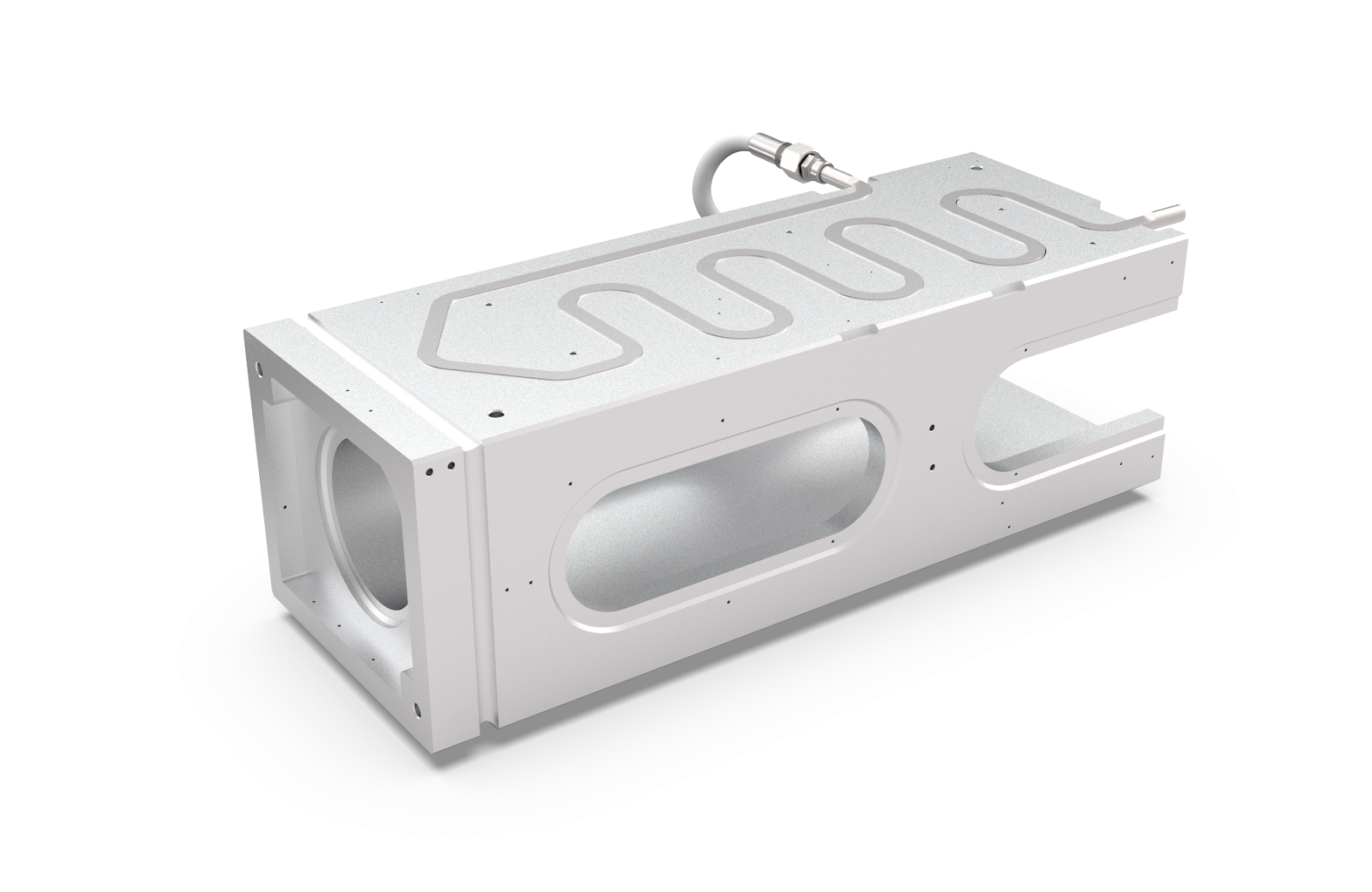

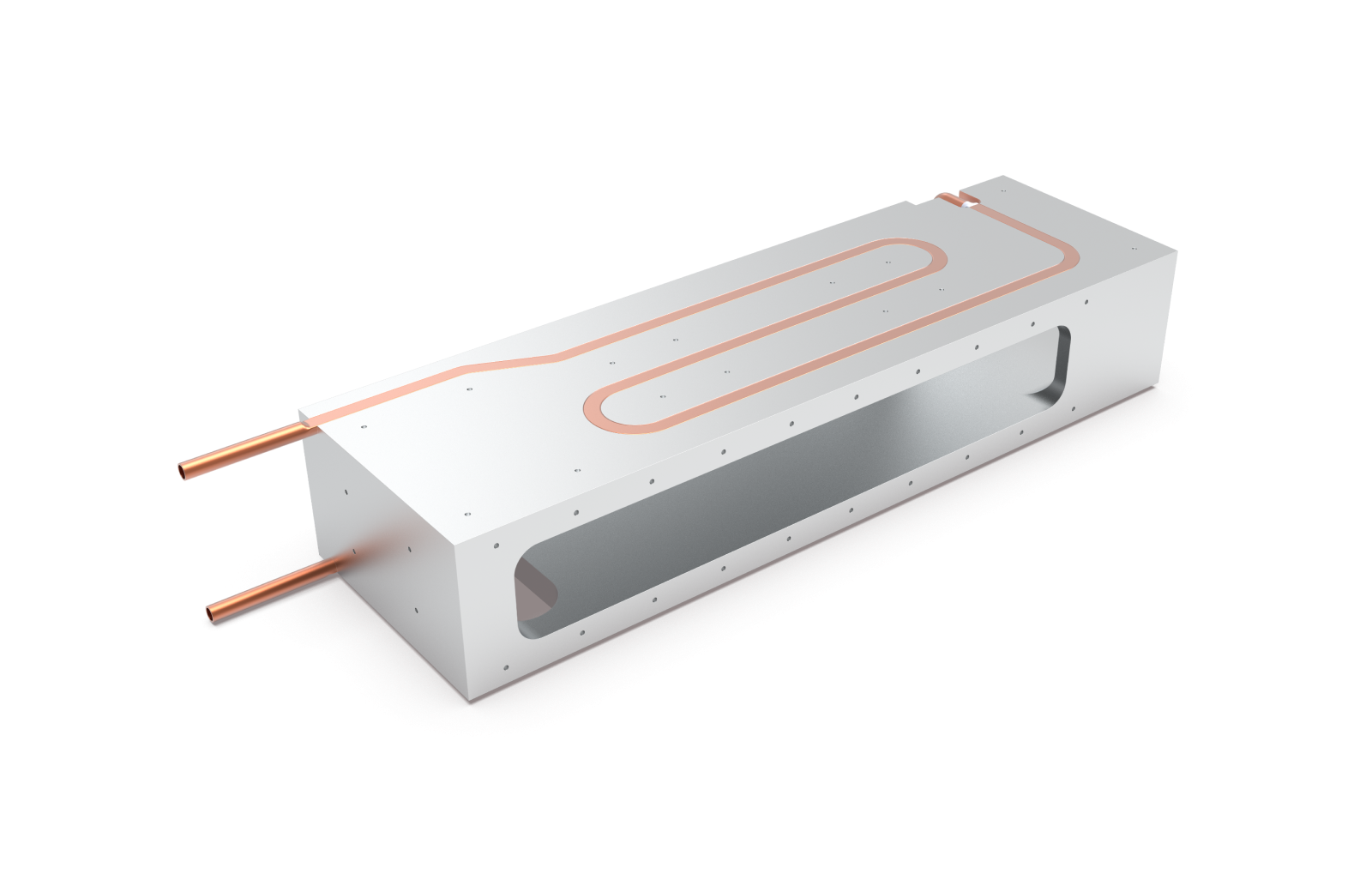

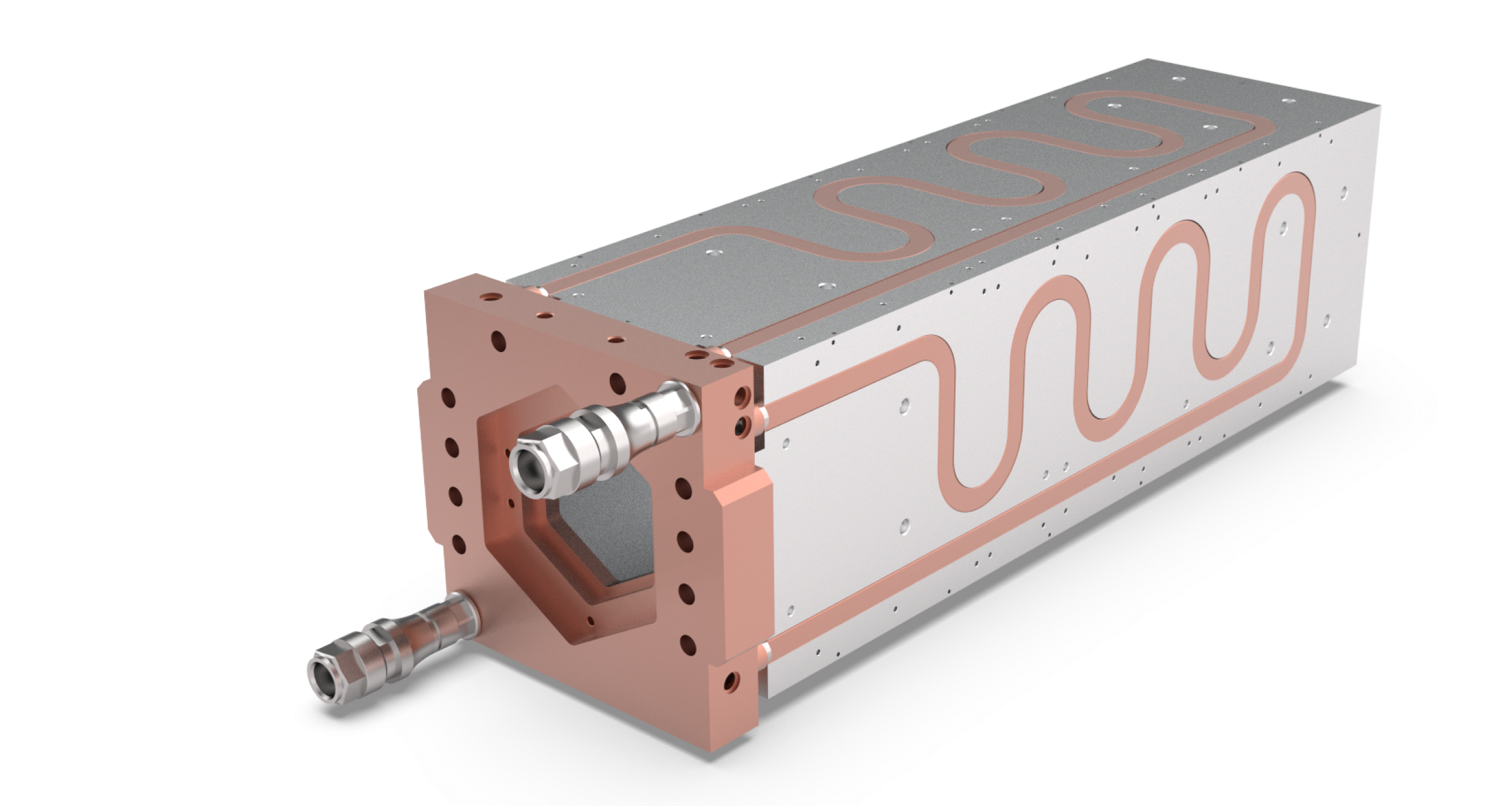

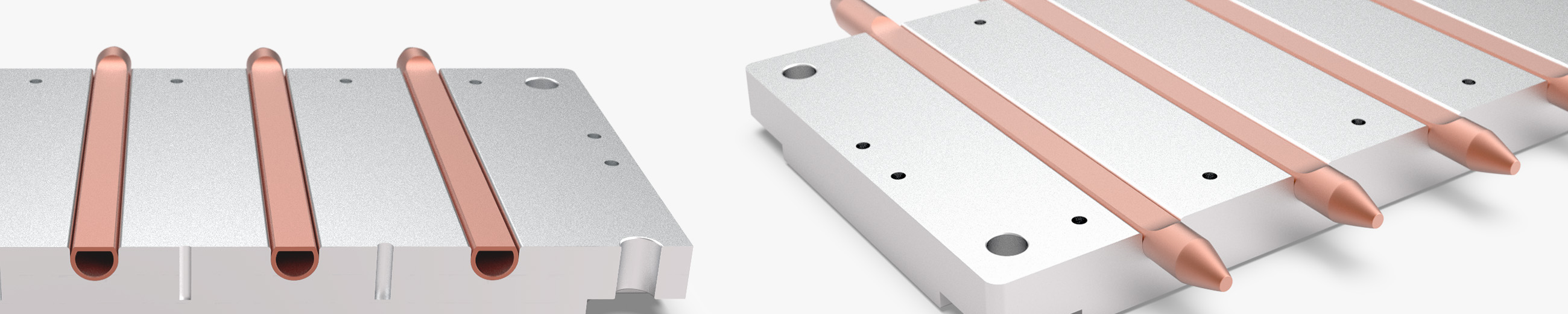

Efficient multi-sided cooling for compact high-performance applications. Tubes press-fitted on up to four sides of the base body ensure maximum heat dissipation in all directions.

Learn more in a personal consultationThanks to our unique groove and press-fit technology, heat is efficiently transferred on every side of the cooler.

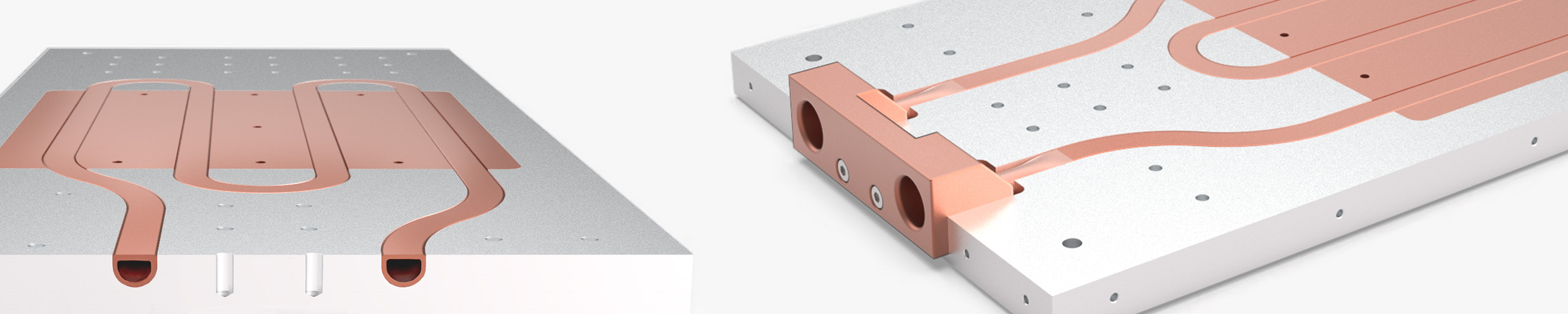

Maximum thermal conductivity through positive and frictional contact

Optimal flatness without outgassing or deformation

Uniform cooling across all active surfaces

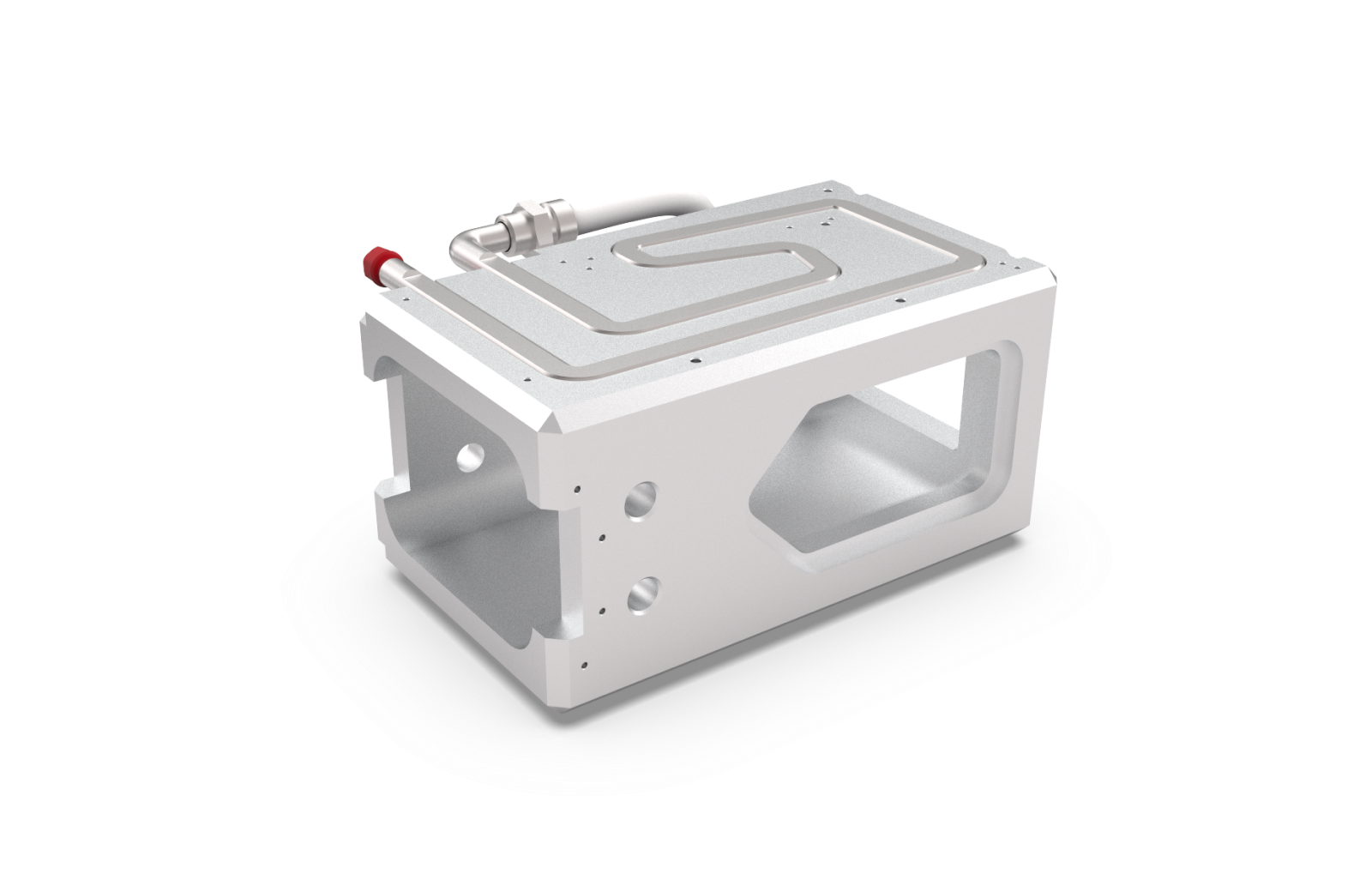

Custom-designed internal spaces – ideal for compact, complex applications

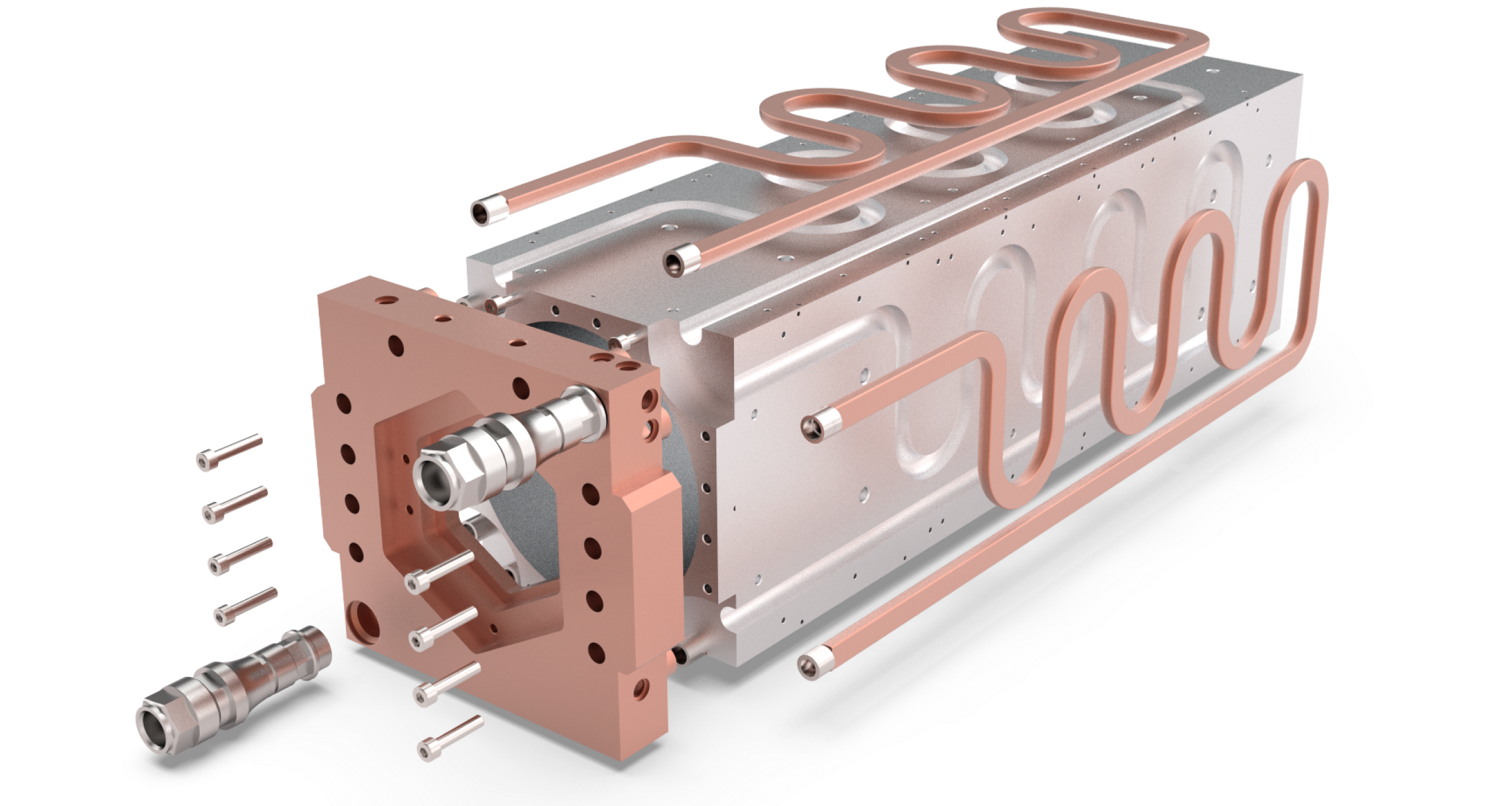

Multiple tubing systems possible without structural deformation

Precision press-fit technology for high dimensional accuracy and stability

Thermally, mechanically, and structurally optimized for the application

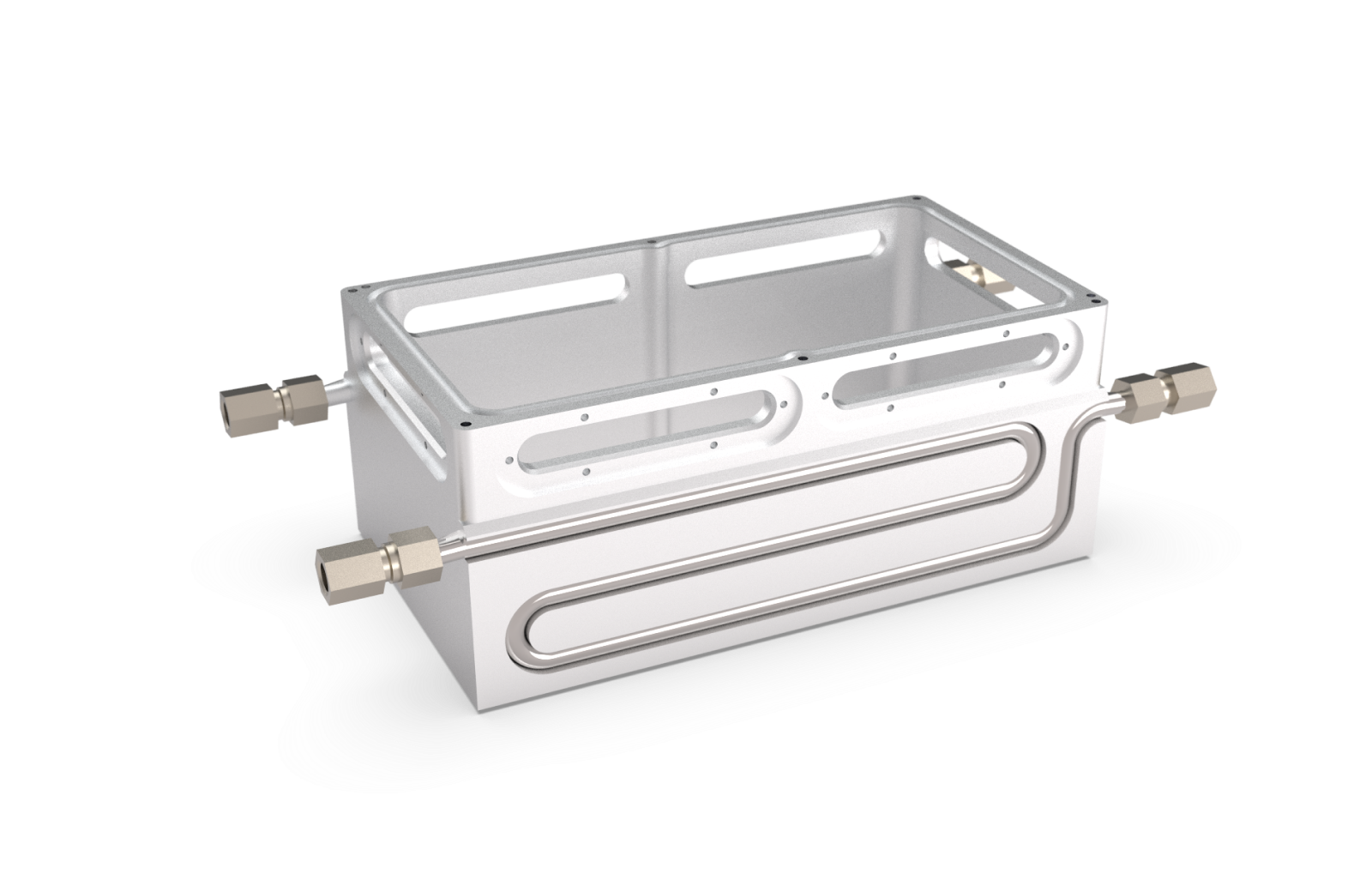

Flexible combination of standard and custom fittings

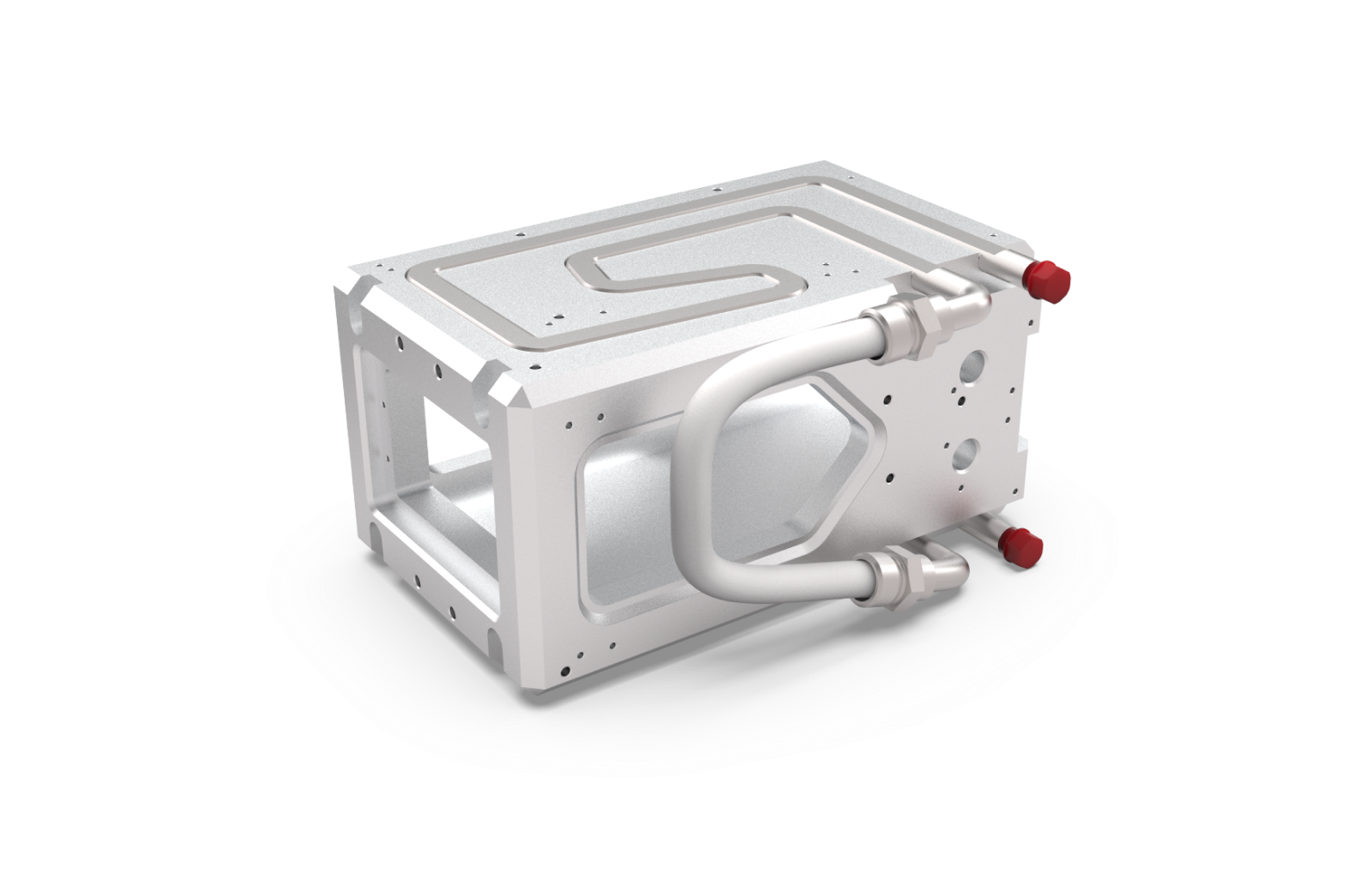

Internal, front-side, or externally mounted connections possible

Front-mounted water distributors for even coolant distribution

High integration flexibility into various system architectures

Reliable assembly and application-specific adaptation

Multi-sided component cooling is ideal for complex applications in compact spaces and forms the functional core of advanced systems.

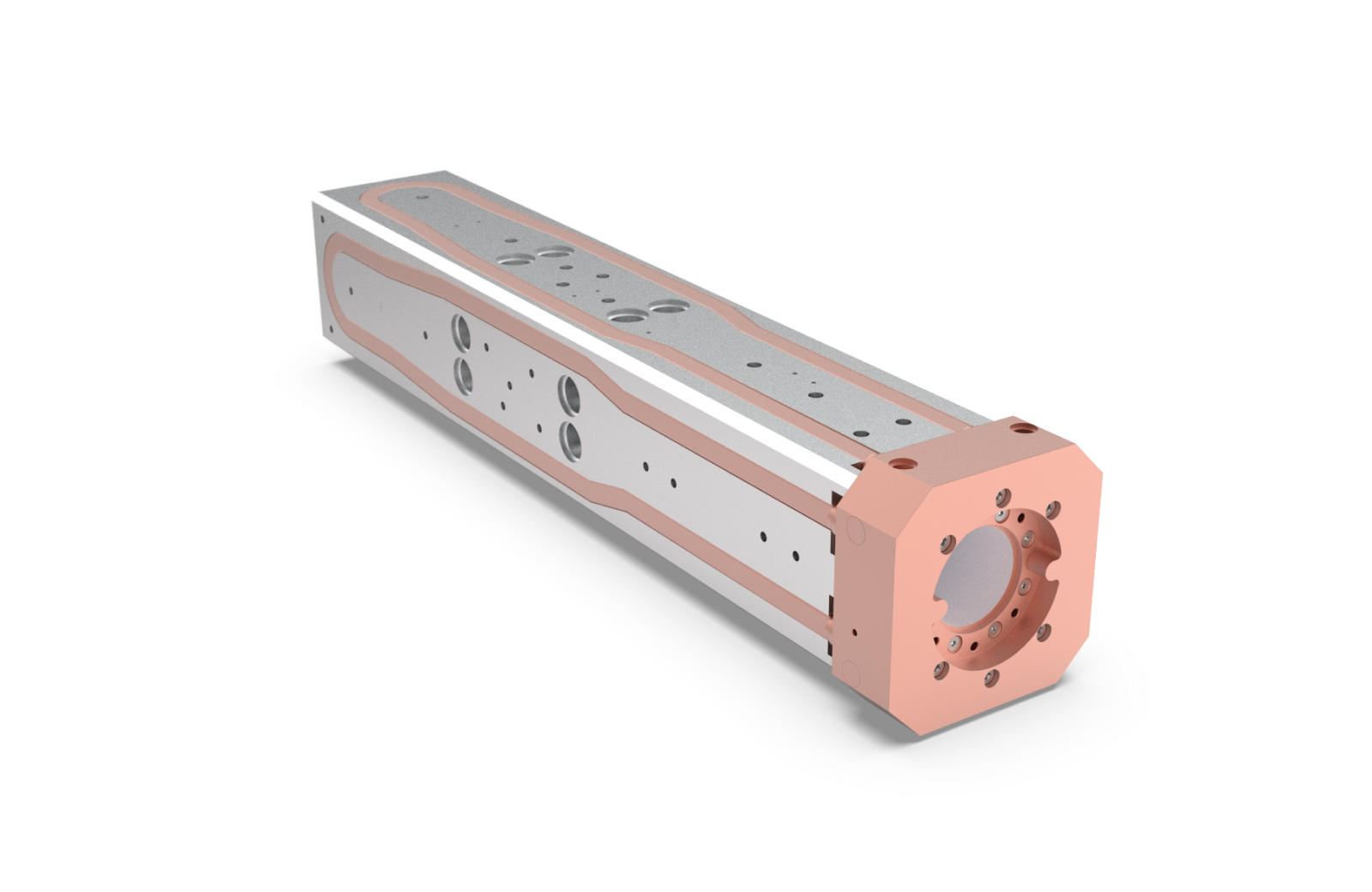

Each Multipress cooler is individually designed so that internal structures and tube layouts are precisely matched to the thermal requirements – for example, in EUV, high-frequency, or laser technology.

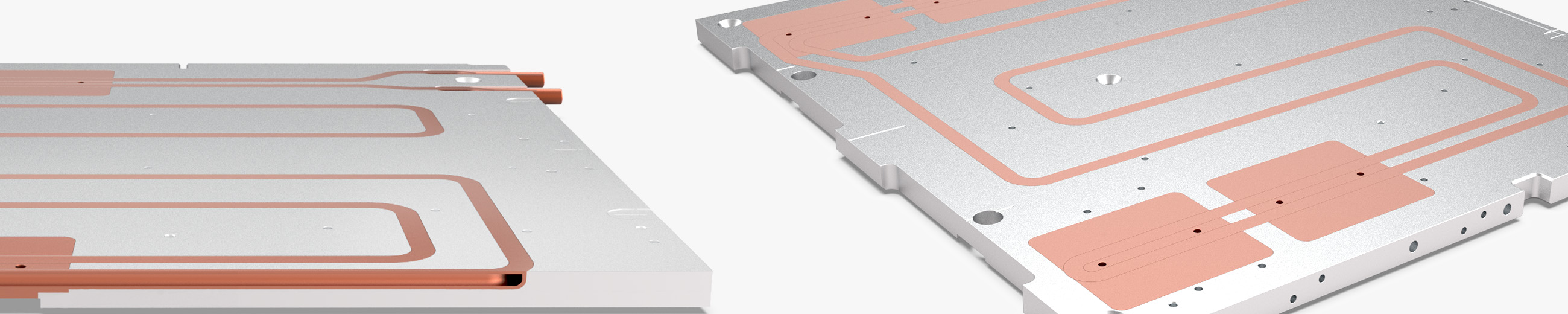

The fluid circuit can be realized either with press-fitted tubes or precisely milled internal structures, and supplied via one or more inlets and outlets to ensure maximum performance.

Learn more in a personal consultation

Multi-sided heat dissipation: Tubes press-fitted on up to four sides

Highest efficiency: No adhesives, no foreign media → direct metallic contact

Flexible integration: Custom connectors, manifolds, and internal layouts

Precision manufacturing: CNC-milled flatness for optimal sealing and assembly

Thermal stability: Even heat distribution in complex assemblies

Proven reliability: Leak and tool-breakage testing for maximum operational safety

Copper or stainless-steel inserts transfer heat directly to the circulating coolant. These can easily be combined with press-fitted tube systems to further increase overall performance – ideal for applications with high power density or dynamic temperature profiles.

Embedded copper inserts evenly distribute generated heat across all cooling surfaces. This reduces hot spots, stabilizes operating temperature, and extends the lifetime of sensitive electronics.

Built-in heat pipes use phase-change technology to rapidly transfer heat from hot zones to cooler regions. This ensures consistent temperatures, especially in high-frequency or high-power applications.

Using digital thermal simulation, COOLTEC supports you in the fast and precise development of your customized cooling solution.

With over 30 years of experience in manufacturing technology, performance, material use, and available space are optimally balanced – ensuring maximum efficiency and short development times.

Benefit from over 30 years of expertise in thermal management and precision engineering. We’ll find the best solution for your application – perfectly tailored, guaranteed.

Multipress coolers are ideal for high power density, limited space, or complex heat sources. Multi-sided tube press-fitting enables uniform heat dissipation in all directions – for maximum efficiency and stability in high-performance applications.

Depending on requirements, copper, aluminum, stainless steel, or special alloys such as copper-nickel are used. Each design is optimized for thermal conductivity, weight, and corrosion resistance.

In Multipress technology, tubes are precisely press-fitted into grooves on multiple sides. The direct metallic contact – without adhesives or fillers – ensures maximum thermal conductivity and long-term sealing.

Performance can be enhanced through fluid-conducting inserts, copper heat spreaders, or integrated heat pipes. Complementary thermal simulations also enable optimal system design.

Multipress coolers offer flexible connection variants – internal, front-mounted, or external. Water manifolds and custom connections ensure even coolant distribution and easy system integration.

COOLTEC develops tailor-made Multipress coolers – from simulation to series production. The result: efficient, reliable liquid coolers perfectly matched to your thermal, mechanical, and spatial requirements.