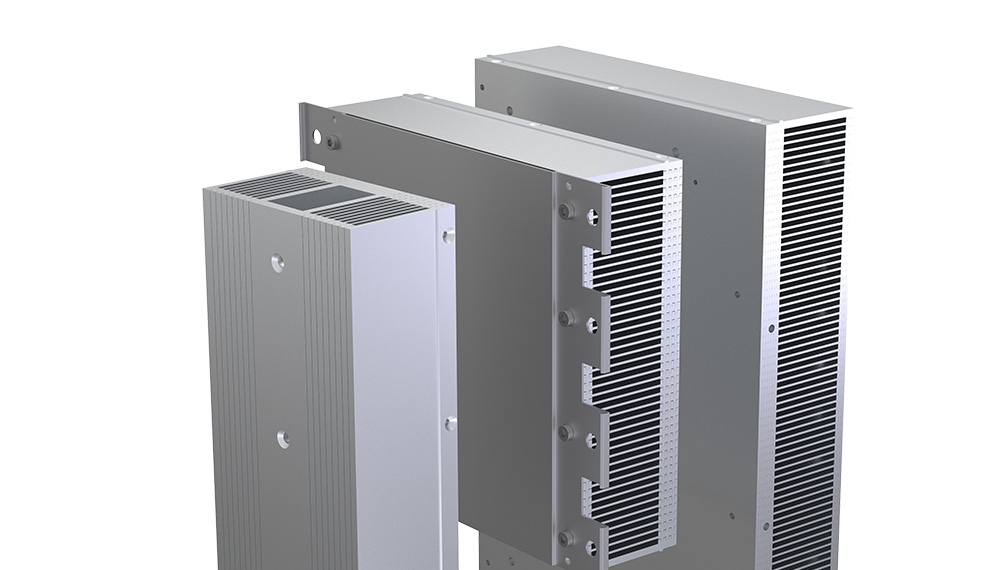

Side Pressed Fin Heat Sinks

Discover how you can cool efficiently in a compact, double-sided design – ideal for limited space.

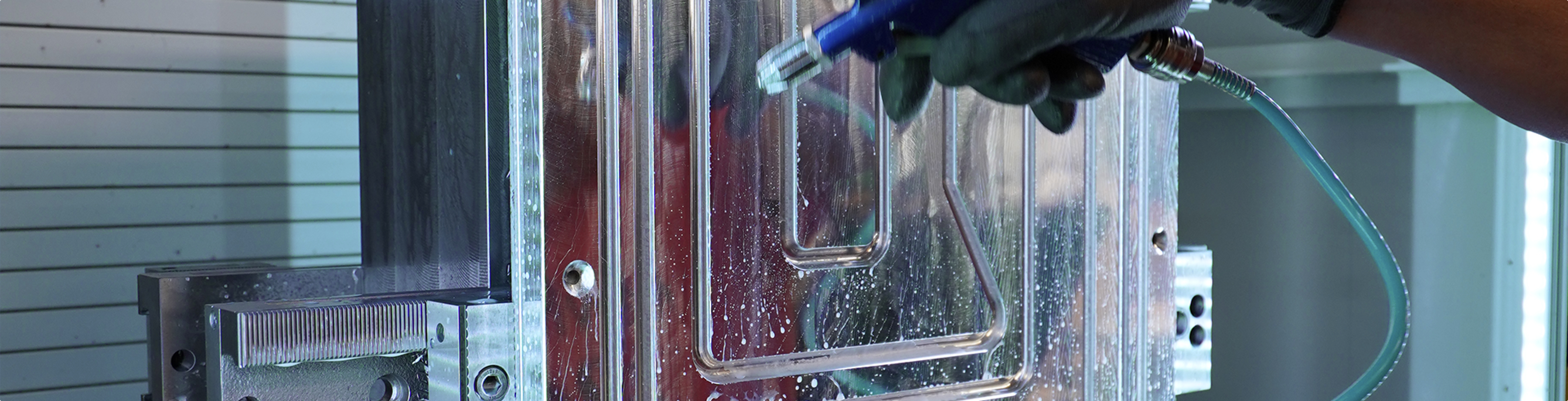

Every liquid cooler is tested for leaks to ensure the system’s safety, reliability, and efficiency. Depending on the requirements, different testing methods are used – from standard tests to highly precise helium leak tests.

Learn more in a conversationThe bubble leak test is a simple yet effective method for detecting leaks.

Process:

The part to be tested is coated with a soap solution.

Pressure is applied to the component.

Bubbles form at leak points that must be repaired.

Ideal for weld seams and seals

Cost-effective and fast

Applicable in food, pharmaceutical, and automotive industries

The pressure drop test checks tightness by monitoring a defined pressure over a set period of time.

Process:

A pressure level is established in a closed system

The pressure is continuously monitored

If the pressure drops, this indicates leaks

Reliable and precise

Early detection of leaks

Suitable for cooling systems and pipelines

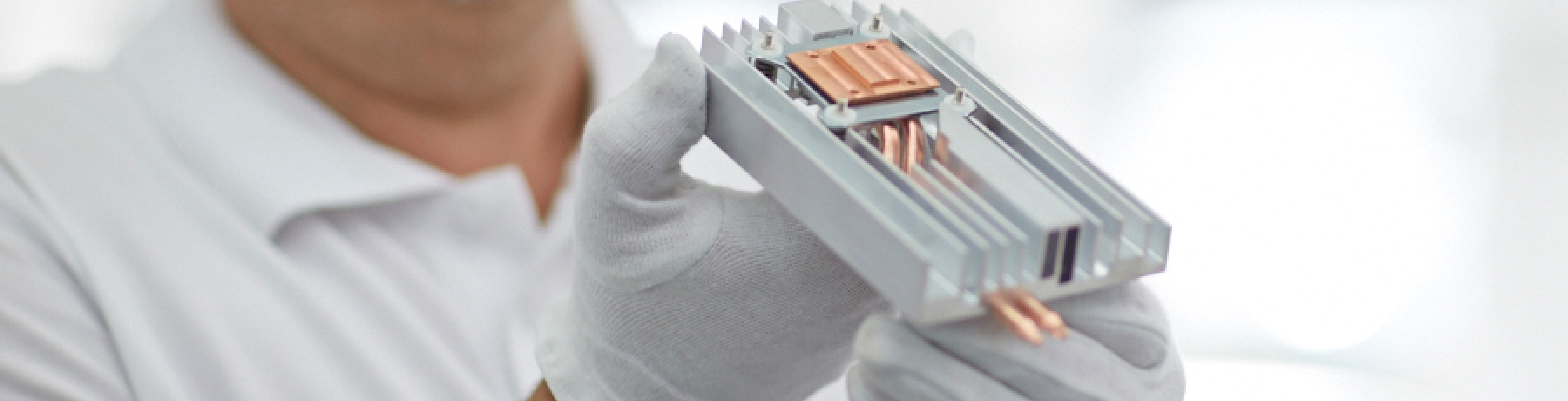

The helium leak test is a high-precision method for liquid coolers that can detect even the smallest leaks.

Process:

The cooler is filled or surrounded with helium

A special detector identifies even minimal gas quantities

Highest accuracy

Detects microscopic leaks

Ensures safety and functionality

The leak test is a key step in detecting leaks early, ensuring operational safety, and avoiding unnecessary costs. Only products that pass this test meet the highest quality standards, which also increases customer satisfaction.

Part cleaning is equally important. During production, dust, oils, greases, or machining residues can remain on surfaces, reducing thermal conductivity and performance. Using modern processes such as ultrasonic cleaning, chemical baths, or high-pressure rinsing, these residues are reliably removed. Especially for liquid coolers with fine internal channels, thorough cleaning prevents blockages and ensures a free coolant flow.

The combination of precise leak testing and careful cleaning ensures that your cooling systems operate efficiently, remain reliable, and achieve maximum service life.

Our precise testing methods ensure your liquid coolers are completely leak-free and reliable. Every leak is detected early for maximum quality and safety.