E-Mobility

Learn how HV batteries, inverters, and power transistors are reliably cooled – compact, efficient, and perfectly tailored for your application.

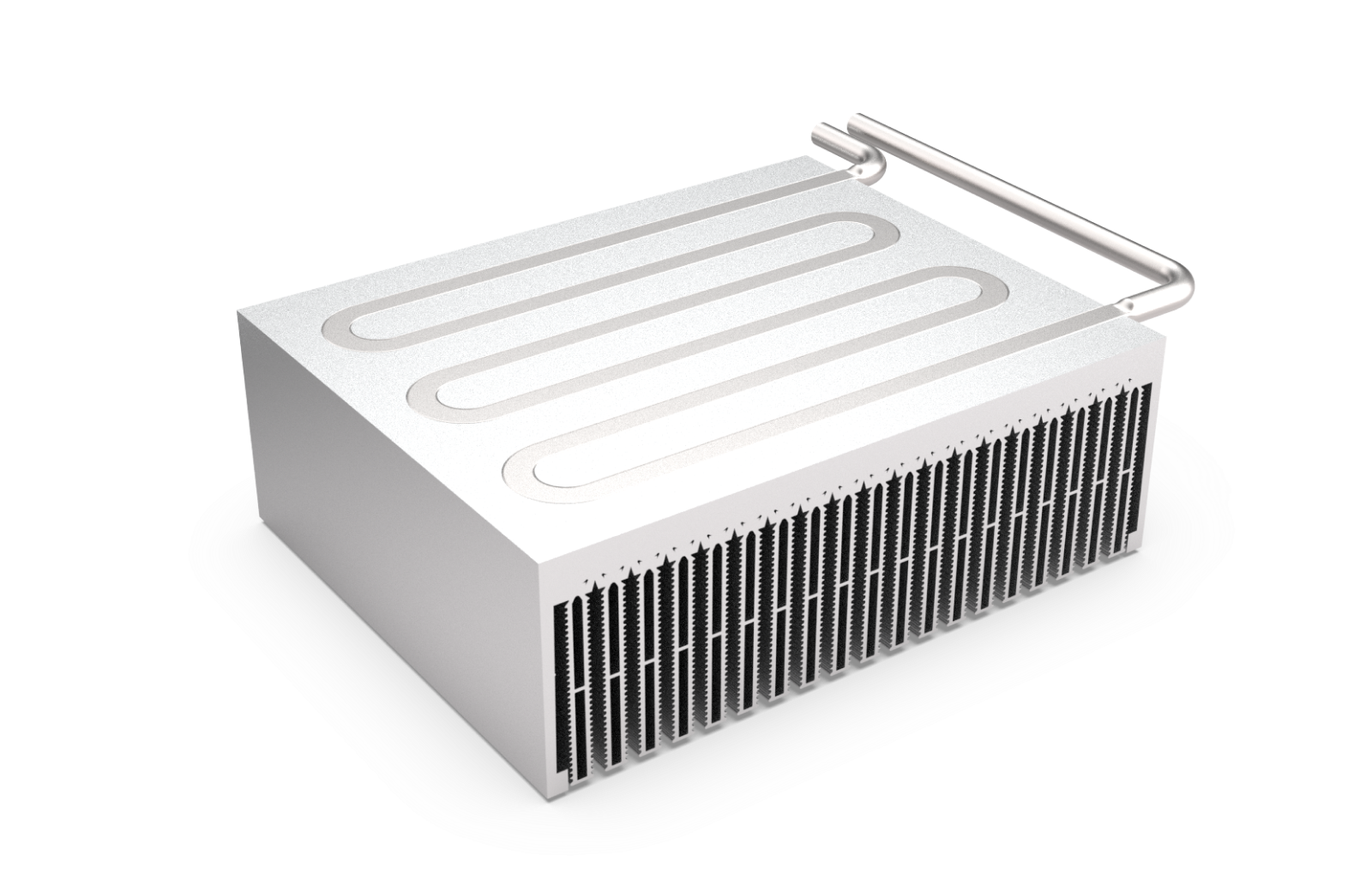

Profile heat sinks with embedded tubes for optimal thermal management – maximum efficiency through the combination of air and liquid cooling.

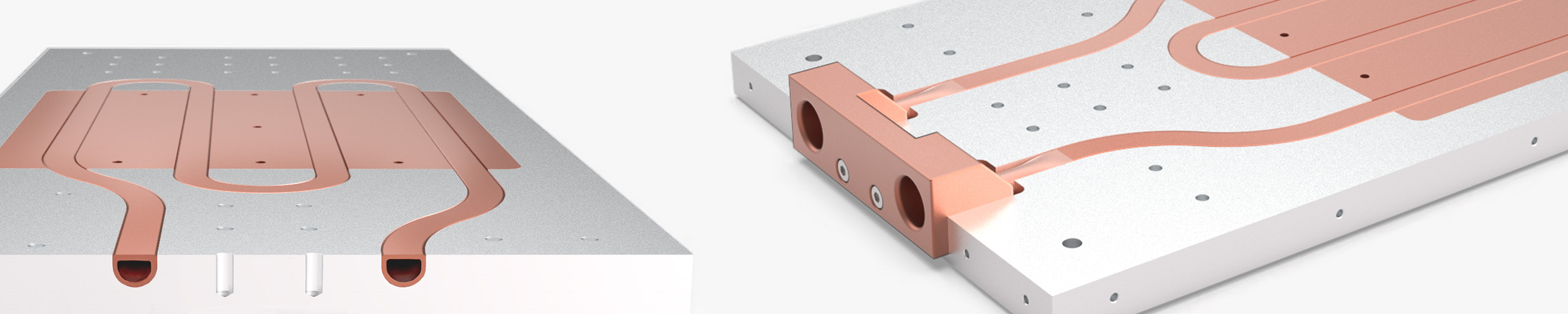

Learn more in a callWe can press a meander structure into any extruded profile according to your specifications. The result is a liquid cooler that combines air and liquid cooling in one system.

Best performance at high inlet temperatures or limited natural convection

Flexible combination of air and liquid cooling for maximum thermal performance

Optional: direct integration of the cooling channel into profiles with sufficient base thickness

Copper, aluminum, stainless steel or special alloys such as copper-nickel

Precise pressing technology for tight radii and complex layouts

Optimal heat transfer without foreign materials or adhesives

Standard or custom connections

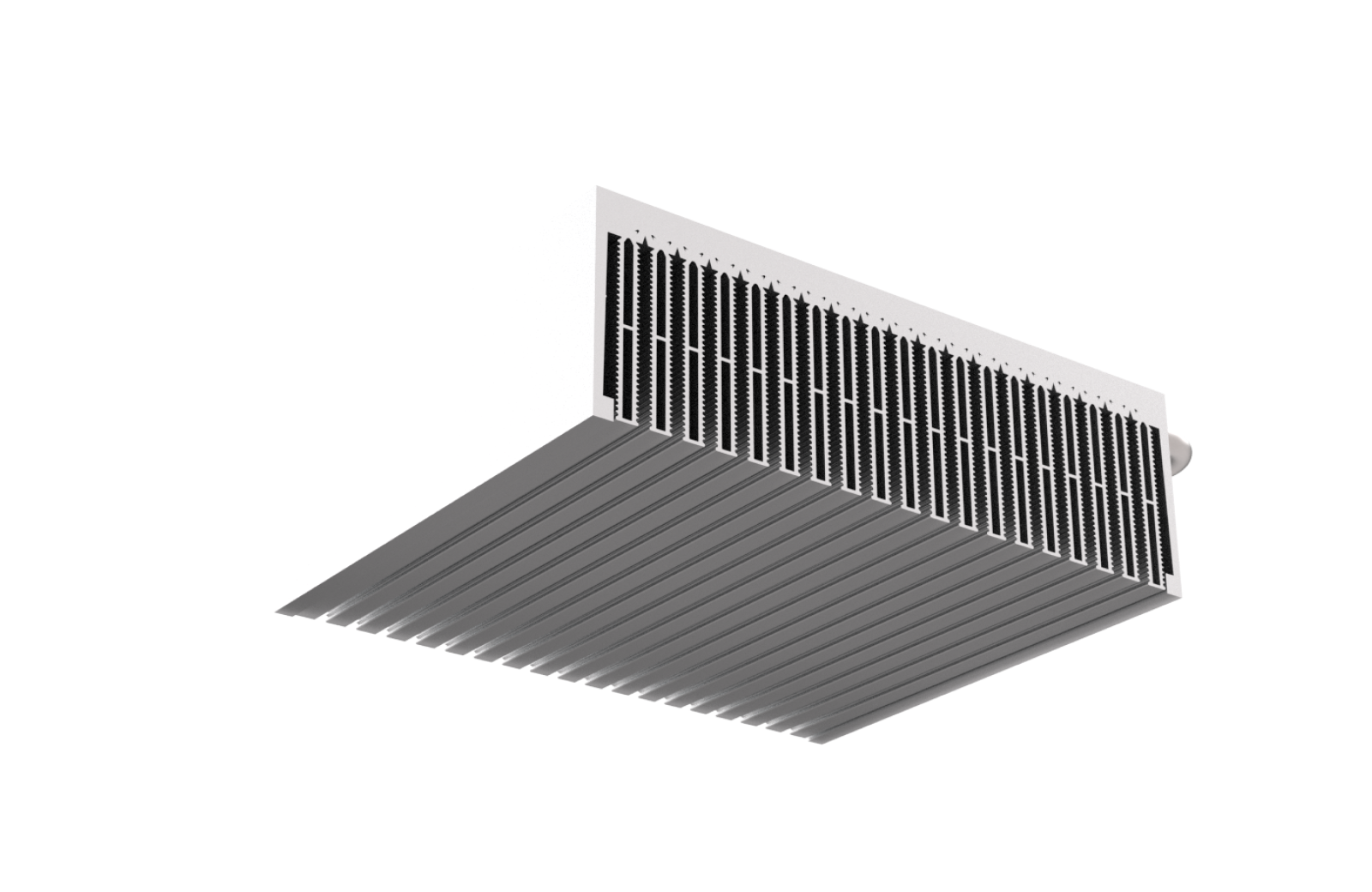

Internal, front-side or external mounting

Front-mounted water distributors for uniform coolant distribution

Easily adaptable to different systems and layouts

In thermally demanding applications, Finpress combines air and liquid cooling for maximum efficiency.

Extruded profile coolers are connected with liquid circuits depending on the application, allowing targeted heat dissipation. The design can be customized to avoid hotspots and ensure uniform operating temperatures.

Learn more in a call

Combined Cooling: Air and liquid cooling for maximum thermal performance

Flexible Integration: Press-fitting according to customer specifications, direct channel integration possible

Precision Manufacturing: Extruded profiles and press-fittings for highest dimensional accuracy

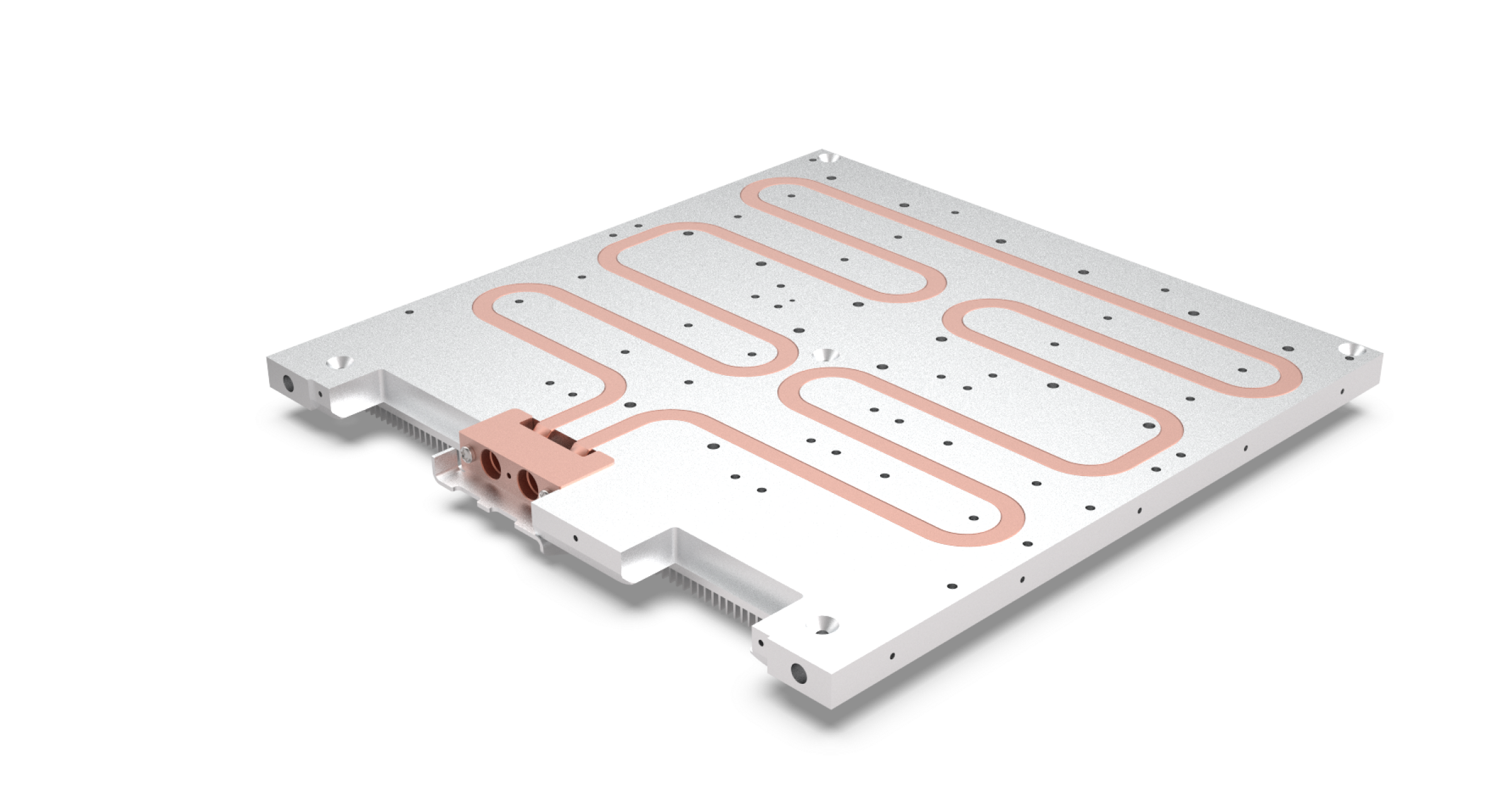

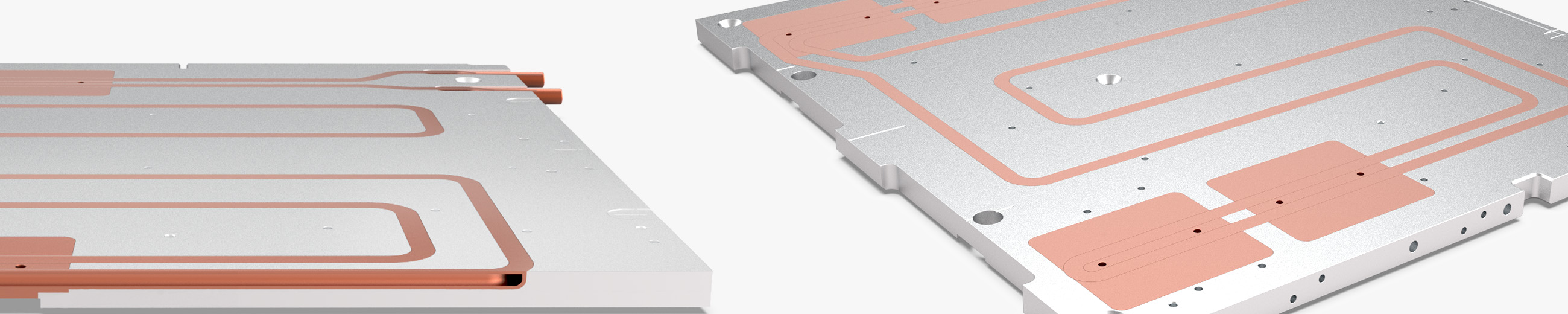

Fluid-Carrying Inserts: Copper or stainless-steel inserts for optimal heat transfer

Embedded Copper Inserts: Uniform heat distribution, stable temperatures

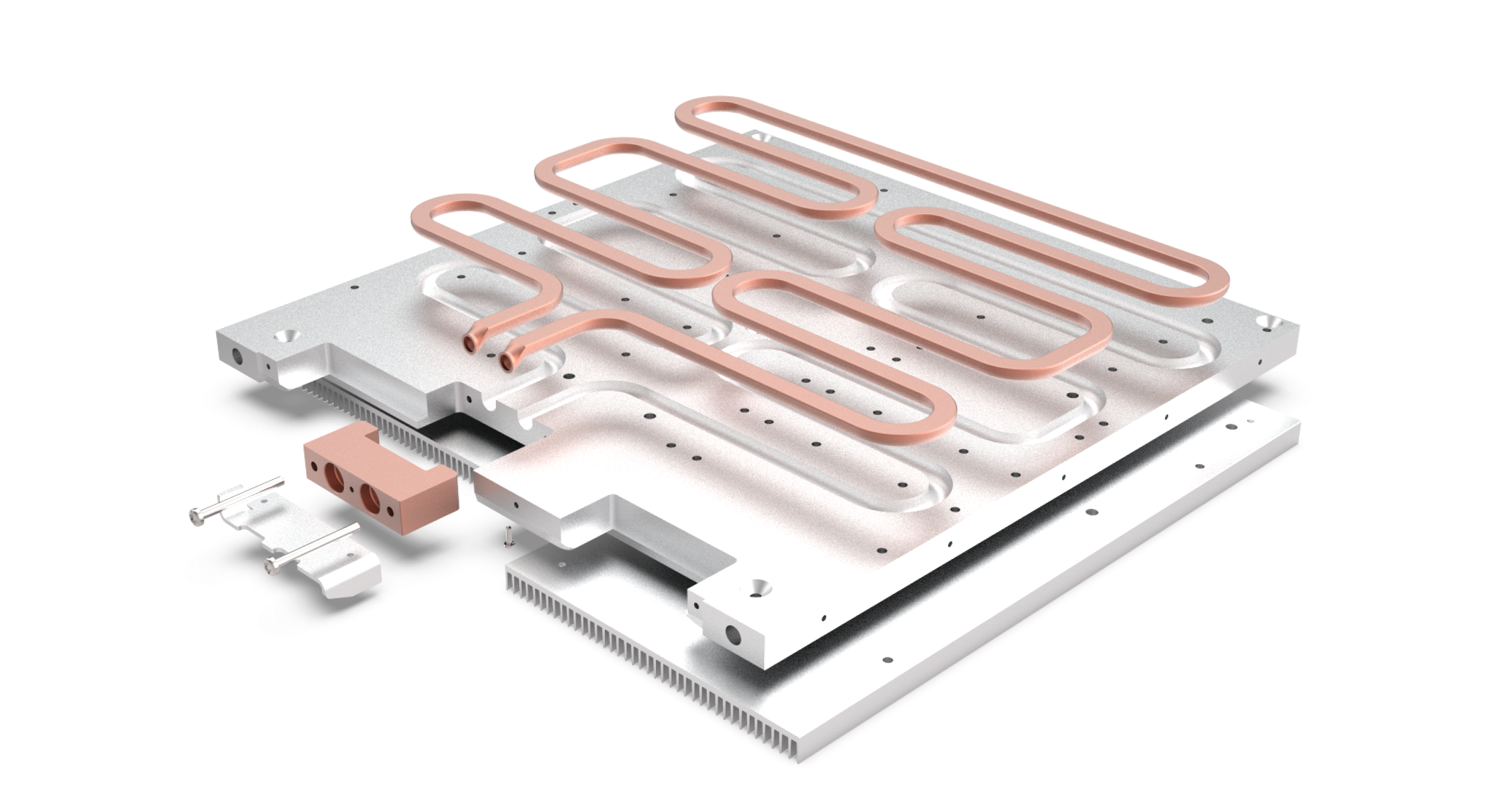

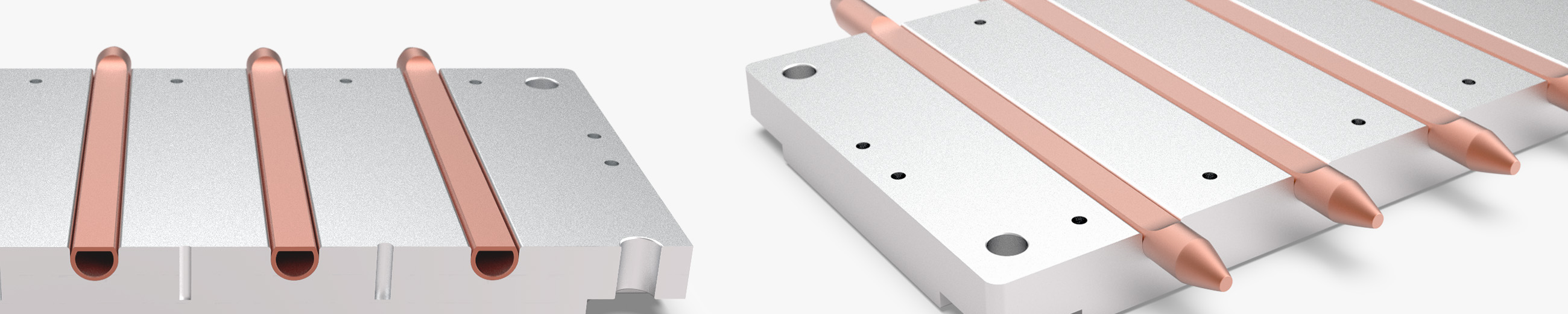

Integrated Heat Pipes: Effective hotspot reduction and increased cooling capacity

Reliability Tested: Leak tests and durable constructions

Copper or stainless-steel inserts transfer heat directly to the circulating coolant. They can be easily combined with embedded tube systems to further increase total performance – ideal for high power densities or dynamic temperature profiles.

Copper inserts evenly distribute heat across the heat sink, reducing hotspots and maintaining stable operating temperatures. They also extend the service life of thermally sensitive components.

Heat pipes use phase change technology to transfer heat efficiently. They significantly increase cooling performance and ensure stable temperatures even in high-performance applications. This minimizes hotspots and improves temperature control.

COOLTEC supports the design of your cooling solution:

Thermal simulations and CAD optimization

Custom design for maximum cooling performance

Short development times thanks to decades of experience

Whether high-performance electronics or limited installation space: we develop cooling systems that combine performance and reliability – fast, precise, and tailored to your needs.

Finpress coolers are ideal when high power densities and compact designs require efficient cooling. They combine air and liquid cooling to prevent hotspots and ensure stable operating temperatures.

Finpress coolers use copper, aluminum, stainless steel, or special alloys such as copper-nickel. The material selection depends on thermal, mechanical, and fluid-related requirements.

The press-fit technology integrates liquid channels directly into extruded profiles. The direct metallic contact enables efficient heat transfer without adhesives or foreign materials.

Performance can be enhanced through fluid-carrying inserts, copper heat spreaders, or integrated heat pipes. Thermal simulations help fine-tune tube layout and flow for the specific application.

Finpress coolers offer both standard and custom connection options. They can be mounted internally, on the front side, or externally – including water distributors for even flow distribution.