Liquid Cooling for Innovative Thermal Management

Air cooling no longer enough? Our liquid coolers get the most out of your system – efficient, compact, and customizable.

Contact us nowTypes & Applications of Our Liquid Coolers

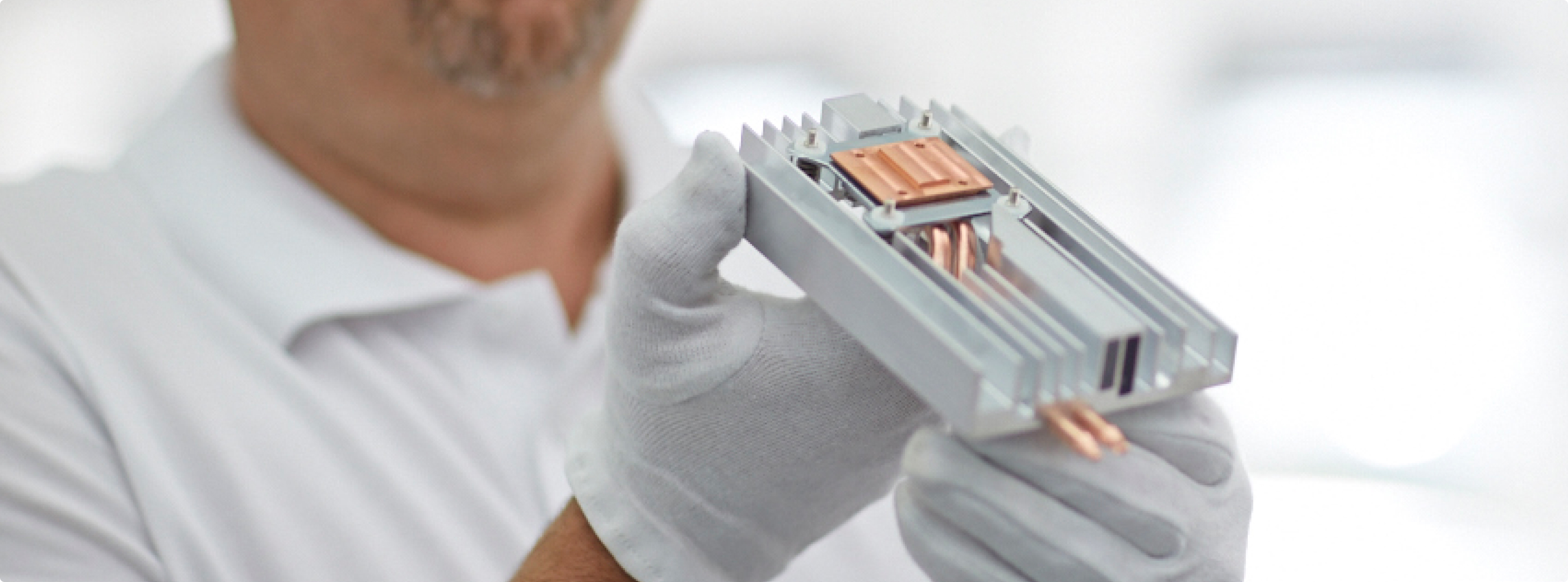

Liquid coolers are the ideal solution for heat dissipation in high-performance applications. Whether for power electronics, mechanical engineering, or laser system cooling – wherever air cooling reaches its limits, our custom-made liquid coolers ensure efficient and consistent thermal regulation.

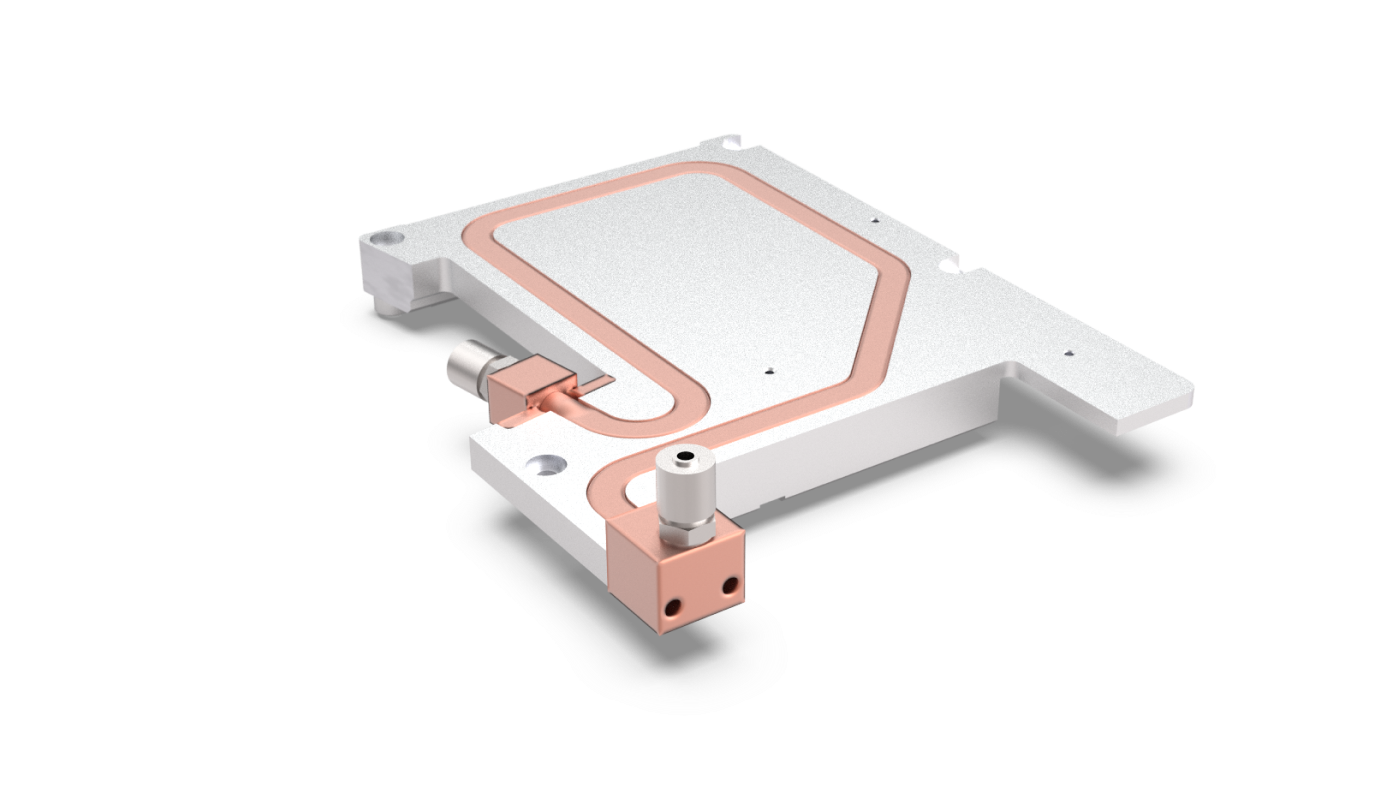

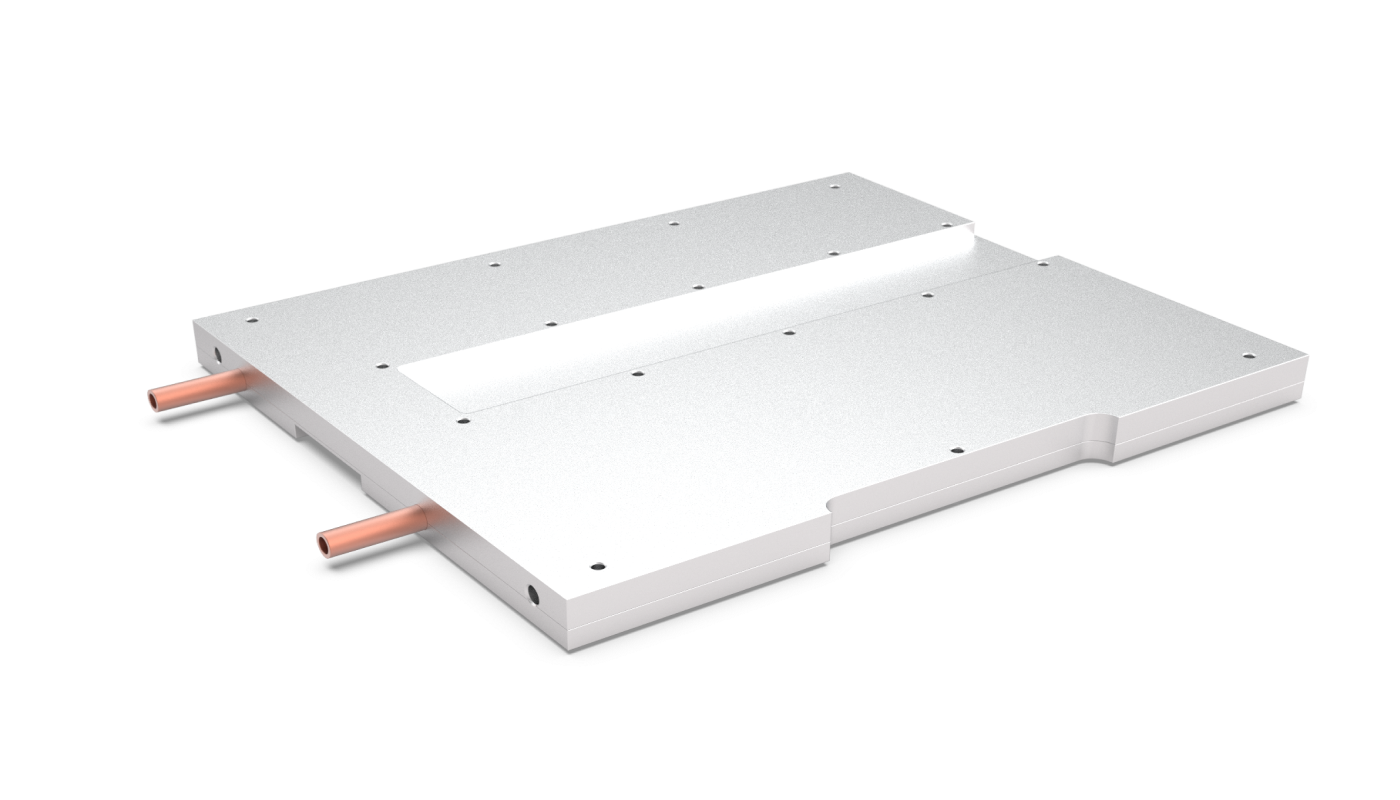

Single-sided Press-in Tubes | Monopress

Precisely pressed-in tubes made of copper, aluminum, or stainless steel for effective cooling of high power losses.Your benefits: Optimal heat transfer, compact design, many connection options

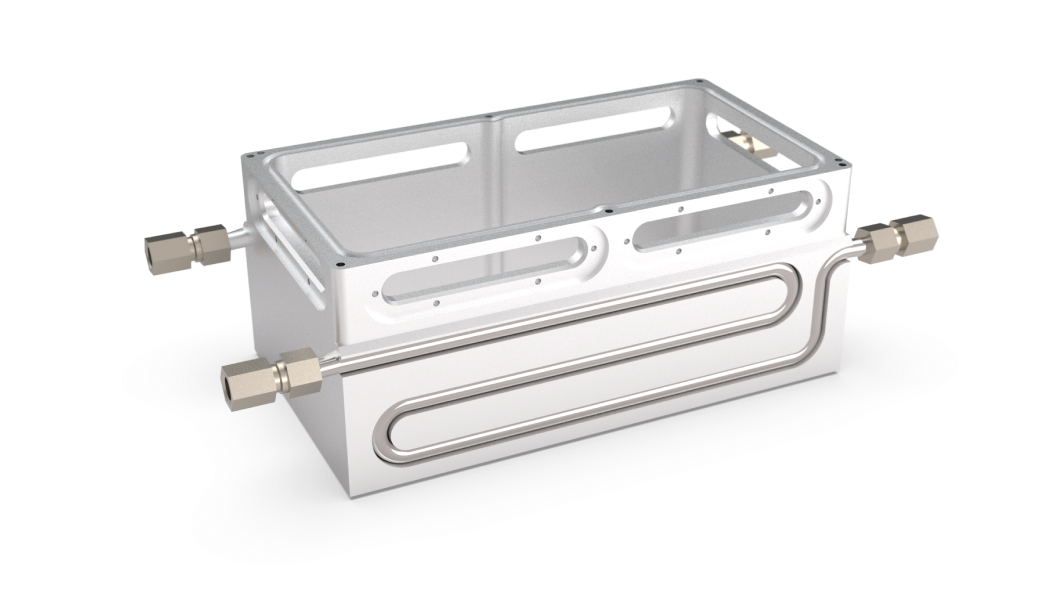

Multi-sided Press-in Tubes | Multipress

Press-in tubes on multiple sides of the heat sink for enhanced cooling performance.Your benefits: Extended cooling surface, flexible design, high efficiency

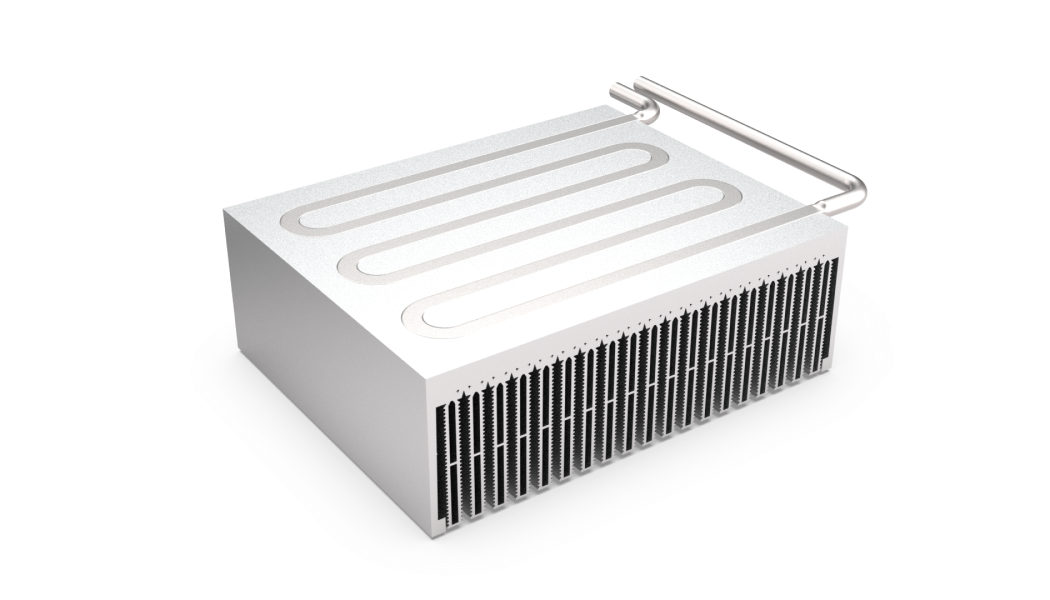

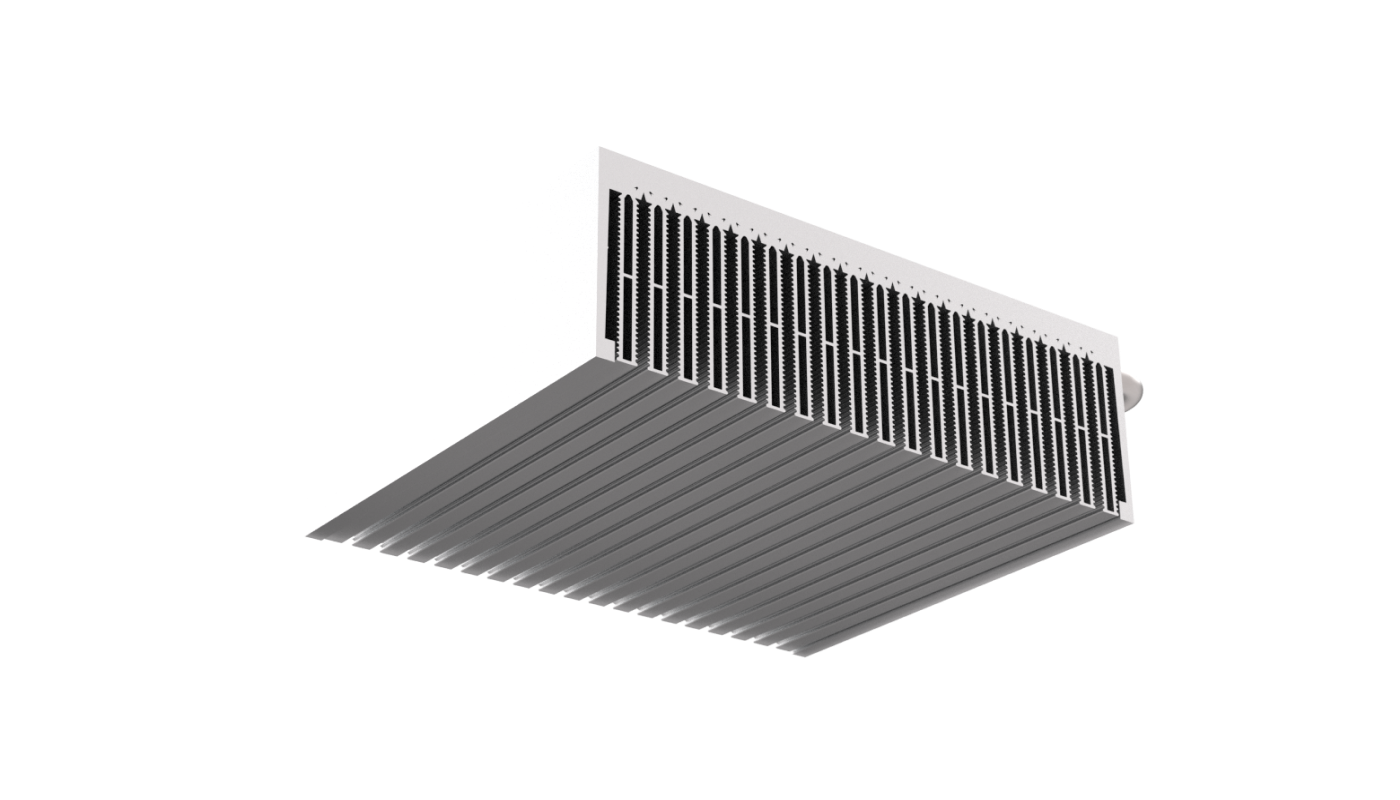

Combined Air/Liquid Cooling | Finpress

Extruded profile heat sinks with press-in tubes for hybrid thermal management.Your benefits: Combined cooling technology, various connection options, effective heat dissipation

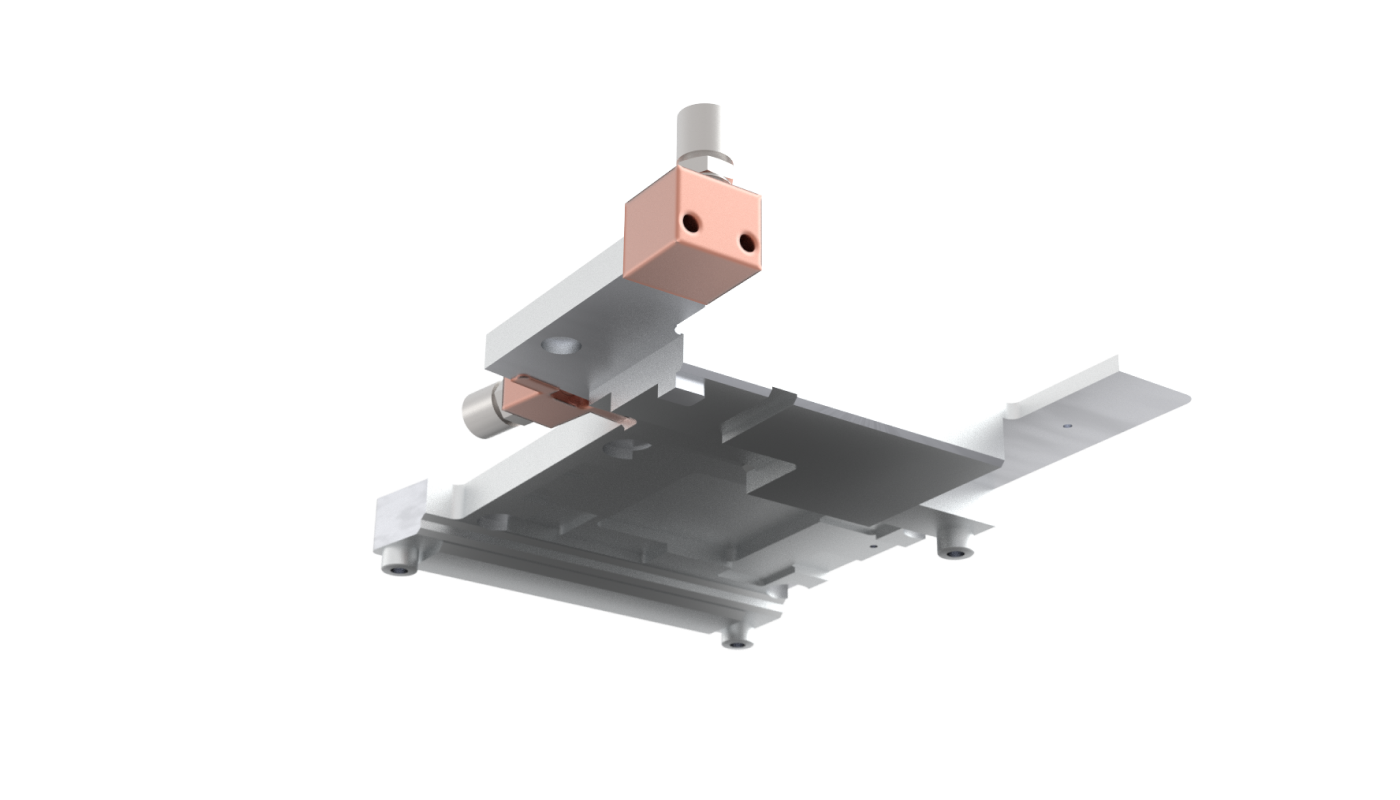

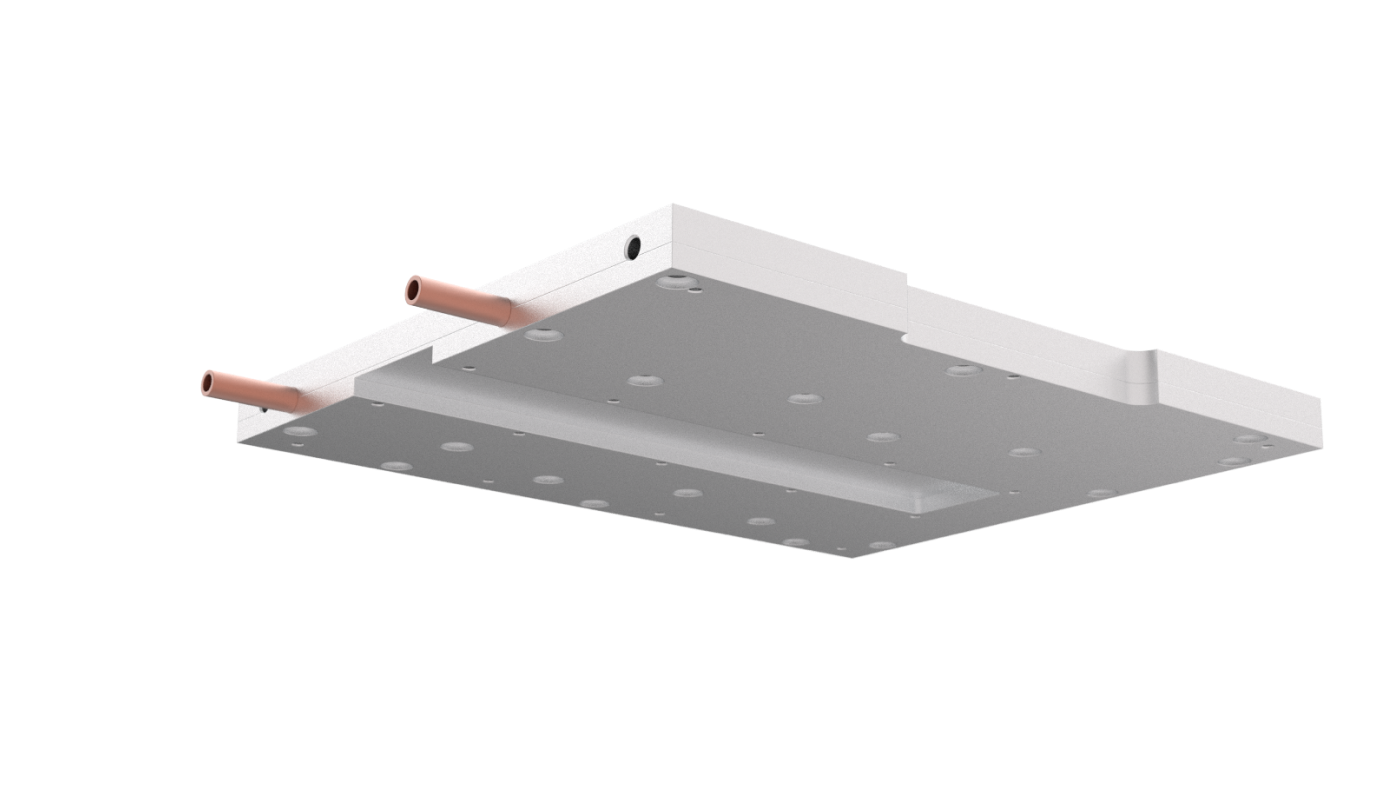

Internal Press-in Tubes | Interpress

Internal tubing enables uniform cooling of components from both sides.Your benefits: Double-sided cooling, optimal thermal transfer, internal tube routing

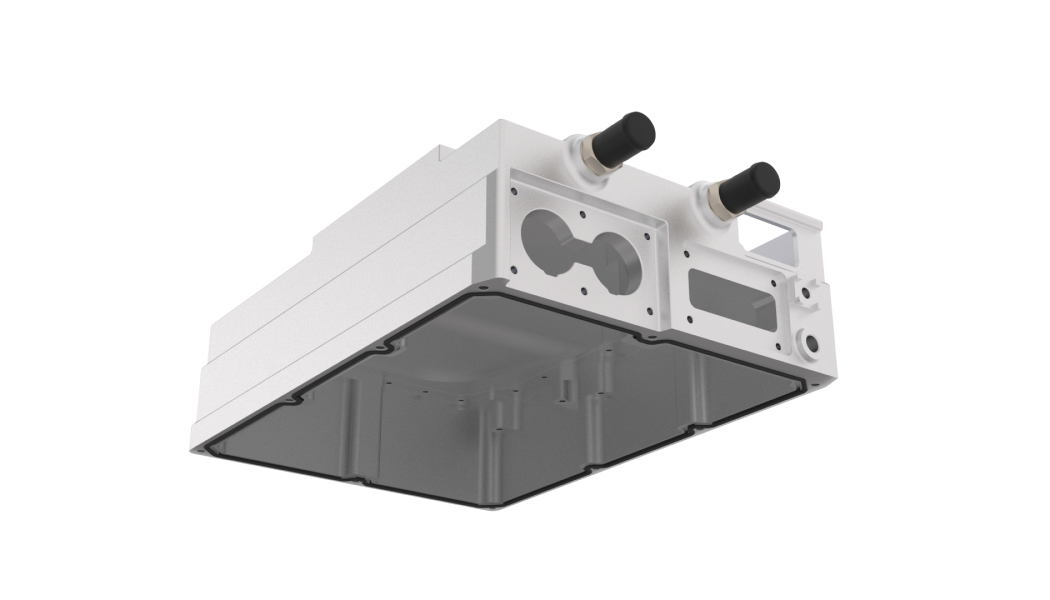

Integrated Housing Coolers | Embeddedflow

Heat sink and housing combined – with integrated liquid circuit for compact system solutions.Your benefits: Space-saving, multifunctional, customizable design

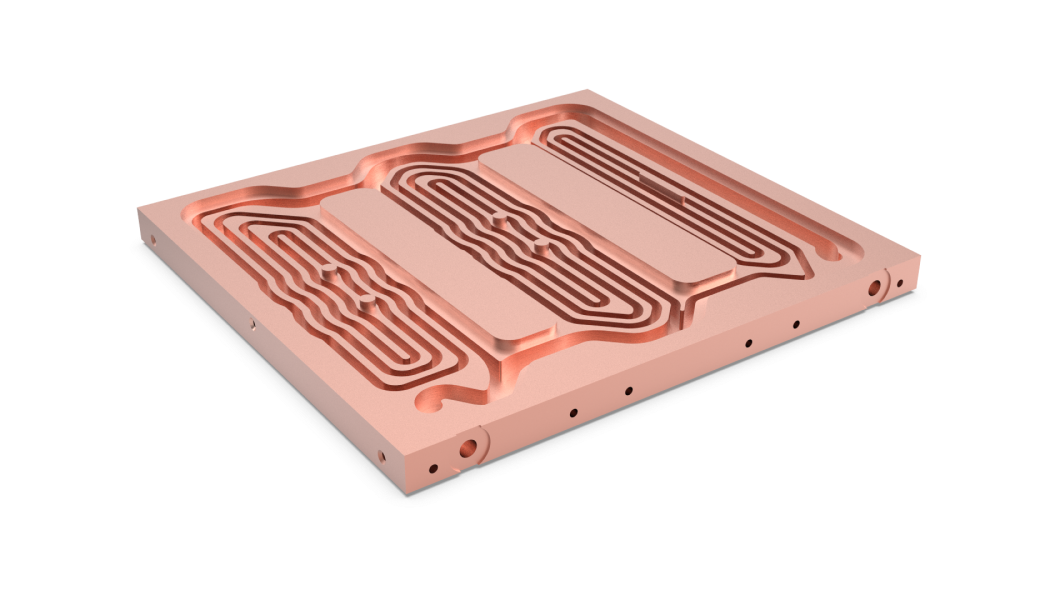

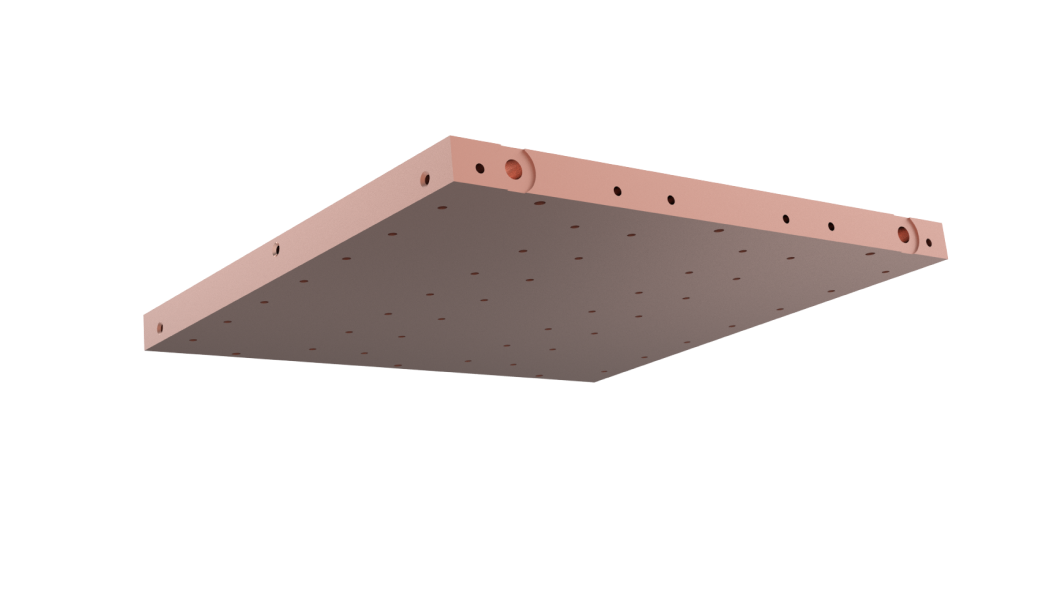

Plates with Internal Structures | Structureflow

Pin, honeycomb, or multi-layer structures combined with vacuum brazing, welding, or bonding for maximum performance.Your benefits: Free technical design, efficient, cost-effective implementation

These customers rely on COOLTEC's cooling solutions

Technology & Function of Liquid Coolers

Liquid coolers, also known as cold plates, are the ideal solution when air cooling reaches its limits – for example in power electronics, laser modules, data centers, or e-mobility applications. Direct heat transfer to a coolant (water, water-glycol, or dielectric liquid) enables up to 10 times more effective heat dissipation – especially when installation space is limited or component density is high.

For maximum performance, COOLTEC uses internally structured cooling plates (Structureflow). Whether complex channels, pins, fins, or multi-layer systems – our coolers are tailored precisely to your thermal requirements. Depending on the design, we use vacuum brazing, welding, bonding, or additive manufacturing.

Benefits of Our Liquid Coolers

Efficient & Compact: Ideal for high thermal loads and tight spaces – liquids transport heat far better than air.

Diverse Forms & Materials: From standard plates to complex internal structures in aluminum, copper, or stainless steel

Customized & Cost-effective: Technically optimized, economically manufactured – perfect for prototypes and small to medium series.

Sustainable Cooling: Recyclable materials, anodized surfaces, and low-CO₂ production for eco-friendly thermal management.

Sustainable Liquid Cooling for Modern Electronics

Our liquid coolers are made from recyclable materials such as aluminum, copper, or stainless steel – ideal for high cooling performance and a low carbon footprint. Aluminum in particular is nearly 100% recyclable and offers excellent thermal conductivity.

Thanks to energy-efficient manufacturing methods like vacuum brazing and optimized material use, our cooling solutions are sustainable – combining environmental responsibility with technical efficiency. This is how we actively contribute to sustainable thermal management in demanding applications.

Sustainability at COOLTECMore Performance. More Safety. More Service.

Quality Assurance & Leak Testing

Every liquid cooler undergoes comprehensive leak testing – such as helium leak detection or pressure testing – and is reliably cleaned. This ensures maximum operational safety and cleanliness for your system.

Coating & Marking

Whether corrosion protection, electrical insulation, or individual serial numbers – we tailor the surface and marking of your coolers precisely to your application’s requirements.

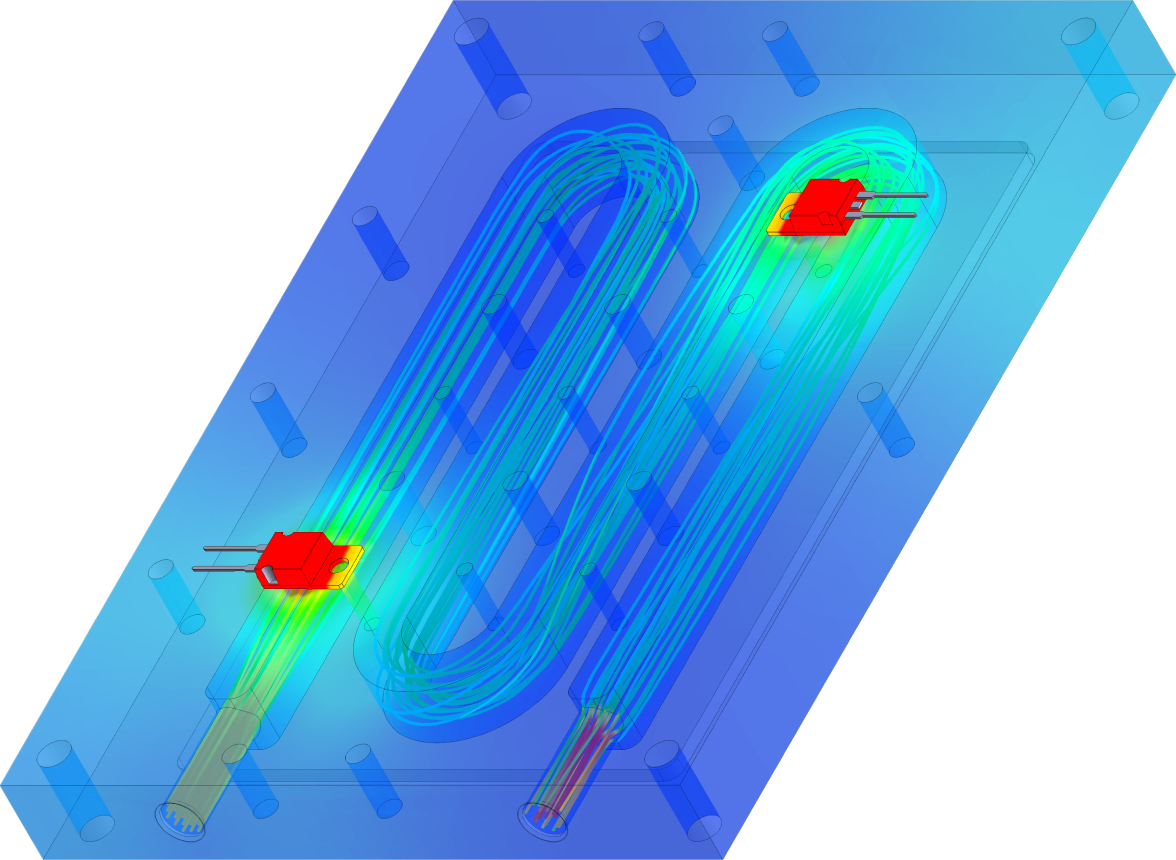

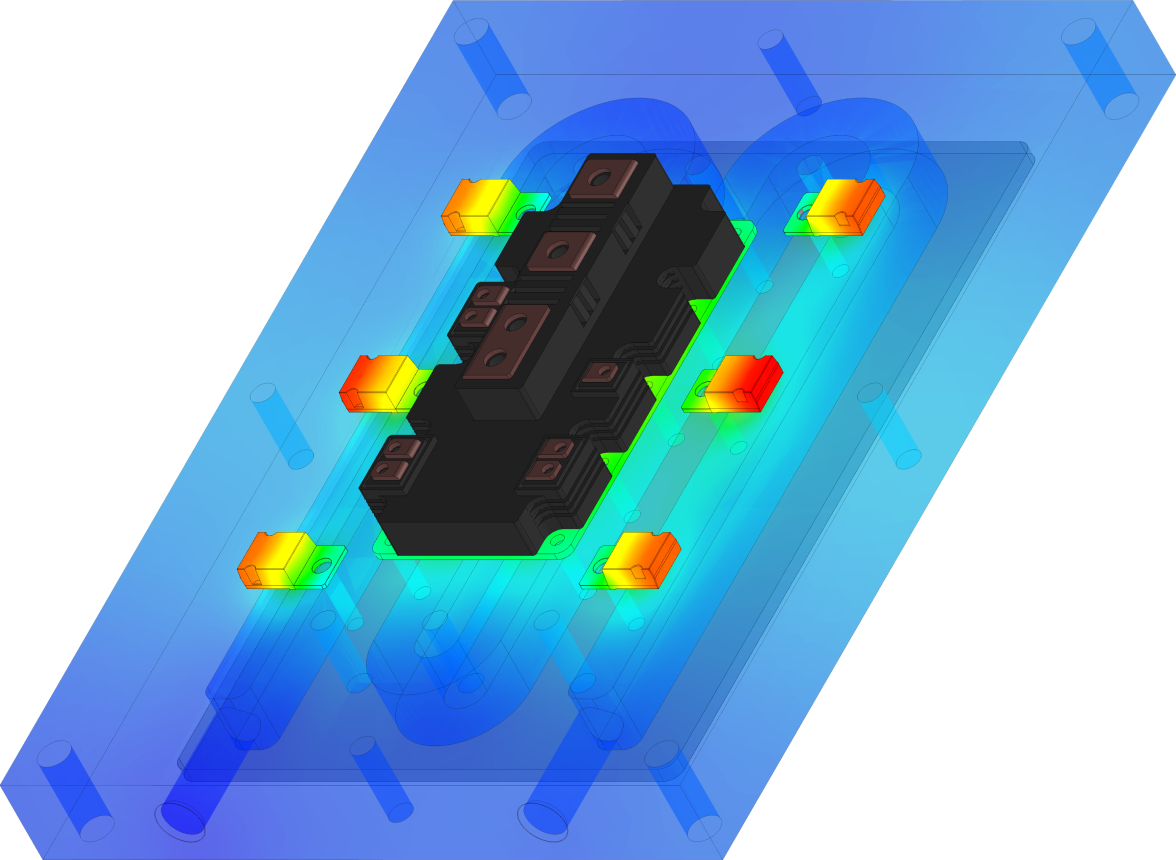

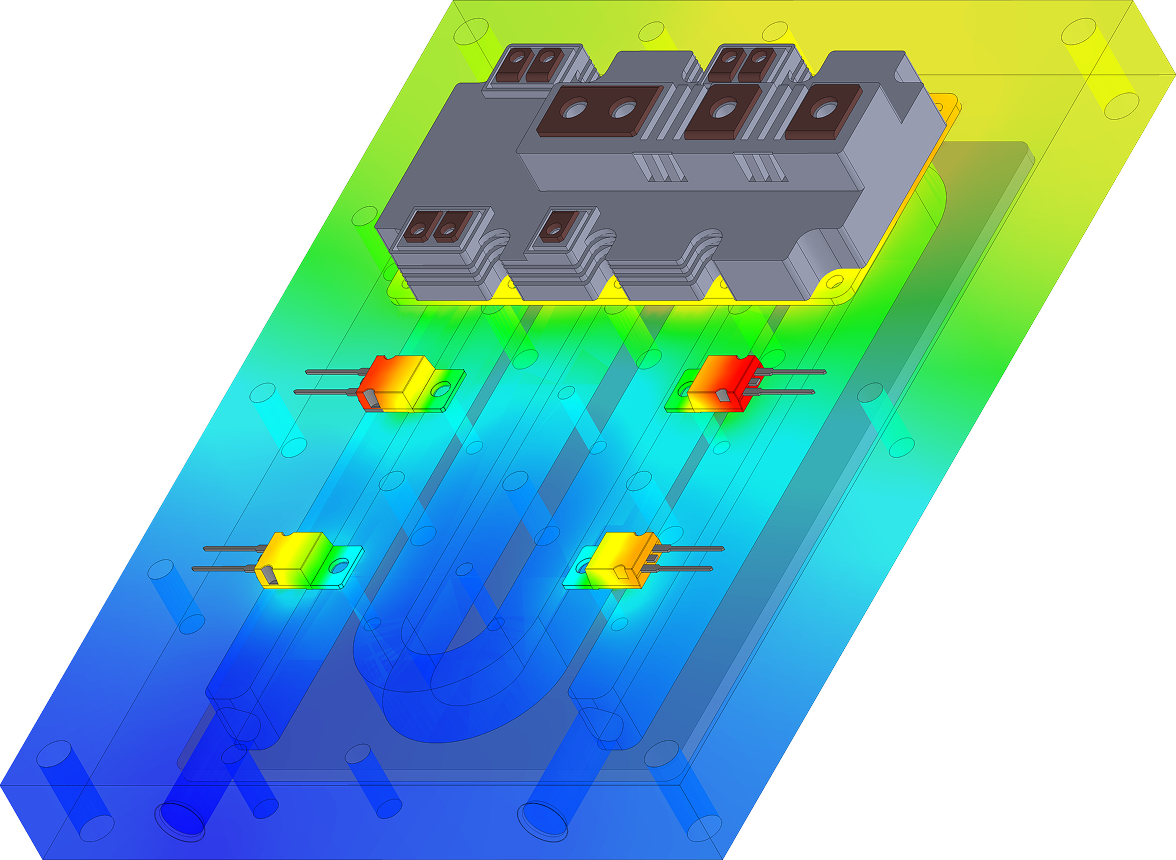

Simulation & Design of Your Cooling Solution

To achieve an optimal liquid cooling solution, several factors must be considered, including:

- Power loss from electronics

- Geometry and available space

- Flow rate and coolant

- Pressure drop and flow guidance

Our thermal simulation tools enable precise design of coolers – including temperature distribution and flow behavior. This ensures maximum efficiency while minimizing risks of hotspots or oversizing.

From Your Requirements to the Solution – We Develop Your Custom Cooler

Whether proven plates for short time-to-market or fully customized solutions – we offer both. Rely on proven designs or develop a custom cooling solution with us for your thermal needs. Get in touch and let’s start your optimal cooling strategy together.

Frequently Asked Questions

A liquid flows through channels or structures inside the cooler, absorbing heat from the component and dissipating it efficiently. The design (microchannels, pins, fins, etc.) significantly impacts performance.

Depending on the application, we use water-glycol mixtures, deionized water, or special non-conductive liquids. We’ll gladly advise you on the right solution, including material compatibility and long-term stability.

Liquid cooling is significantly more effective. The specific heat and thermal conductivity of liquids allow for up to 10 times more efficient heat dissipation – more uniform, more compact, and quieter.

Whenever high power losses need to be efficiently dissipated in a small space. Typical examples: IGBT modules, laser technology, power electronics, e-mobility, or data centers. Liquid cooling is ideal when air is no longer sufficient.

In cooperation with our engineering team. You define the requirements like space, thermal power, or fluid – we take care of design, simulation, and system integration.

Yes. We develop cooling solutions specifically for your application – from single units to series production. We consider structure, joining processes, materials, and system integration.

Properly designed liquid cooling systems require minimal maintenance. High-quality materials, closed circuits, and suitable fluids ensure long service life and low maintenance.