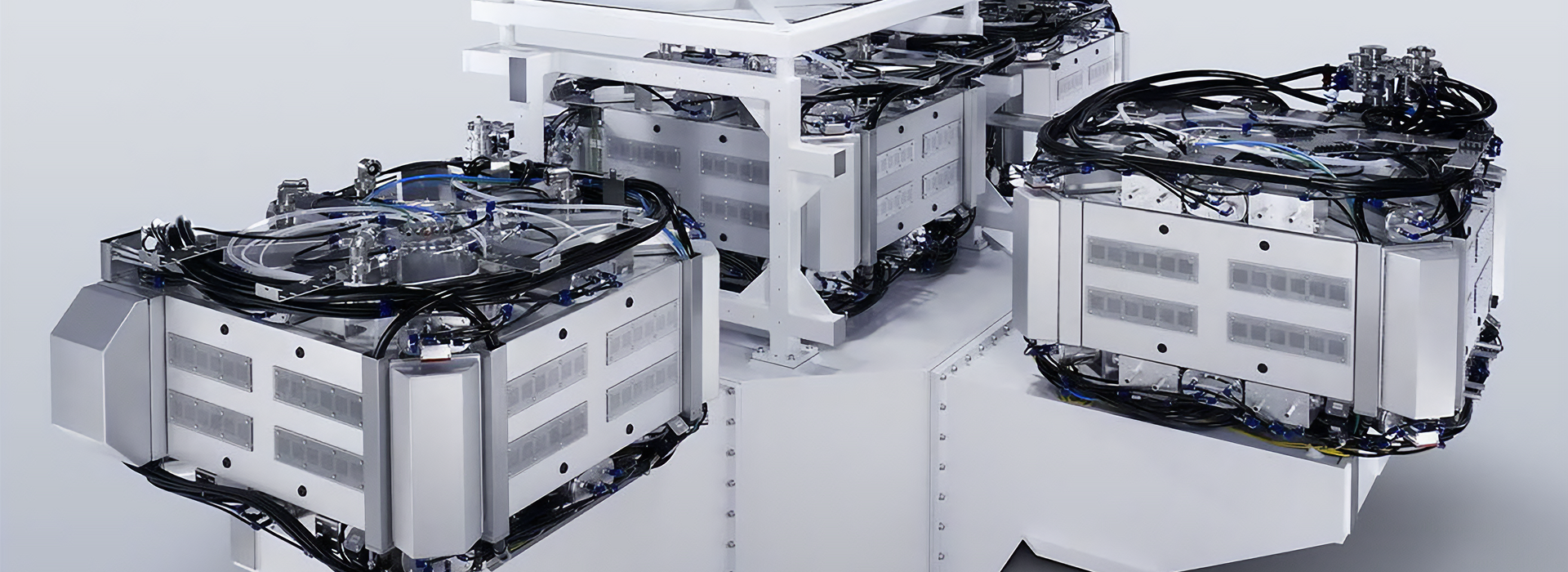

EUV Lithography & Laser Technology: Precision cooling for maximum beam stability

In EUV lithography and laser technology, precise cooling ensures maximum beam quality and reliability. COOLTEC guarantees stability and performance through high-performance cooling solutions.

Why cooling is crucial in EUV lithography and laser technology

Laser and EUV systems generate enormous energy in extremely small spaces. Even minimal temperature deviations can cause beam drift, power loss, or optical distortion. Especially in high-power lasers and semiconductor manufacturing, thermal stability is key to efficiency, process reliability, and product quality.

Learn more in a conversationWithout targeted cooling, you risk:

Beam instability and power loss due to temperature drift

Deformation of optical components

Reduced lifespan of laser diodes, optics, and electronics

Unexpected downtime and quality deviations in production

COOLTEC solutions for EUV lithography & laser technology

With COOLTEC, you benefit from cooling systems developed specifically for the extreme demands of EUV and laser technologies. Our modular high-performance heat sinks and liquid cooling systems enable you to push the thermal limits of your systems – achieving maximum precision in minimal space.

Stable operating temperatures for maximum beam quality

Higher laser output within the same installation space

Energy-efficient thermal management for continuous operation

Reduced downtime through reliable cooling performance

Customizable cooling modules – from prototype to series production

Maximum precision, minimal tolerances

Whether in semiconductor manufacturing, research, or high-power laser applications – COOLTEC ensures that optical systems, laser sources, and power electronics deliver their full performance potential.

Frequently Asked Questions

EUV and laser systems are extremely sensitive to temperature changes. Without targeted cooling, beam stability decreases, components age faster, and production processes lose precision and cost-efficiency.

COOLTEC offers modular high-performance heat sinks, liquid cooling plates, and highly efficient heat exchangers – designed for precise temperature control with minimal thermal resistance. Ideal for high-power lasers, optics, and precision electronics.

Yes. All systems are modular and can be individually adapted to performance, space, and thermal requirements – from prototype to mass production.

Developers gain thermal reliability and design freedom, while purchasers benefit from competitive pricing, process-safe manufacturing, and high delivery reliability.

- High-power lasers & laser diodes

- Optical components and beam sources

- Power electronics and driver units

- EUV optics and mirror modules

Get your Cool How Report 2026 now

Efficient thermal management for the high-tech industry

Learn how to optimize cooling for high-tech applications – with solutions that are efficient, reliable, and ready to implement.

Download report