Semiconductor Industry

Discover how effective cooling improves process stability in wafer manufacturing, test systems, and chip production.

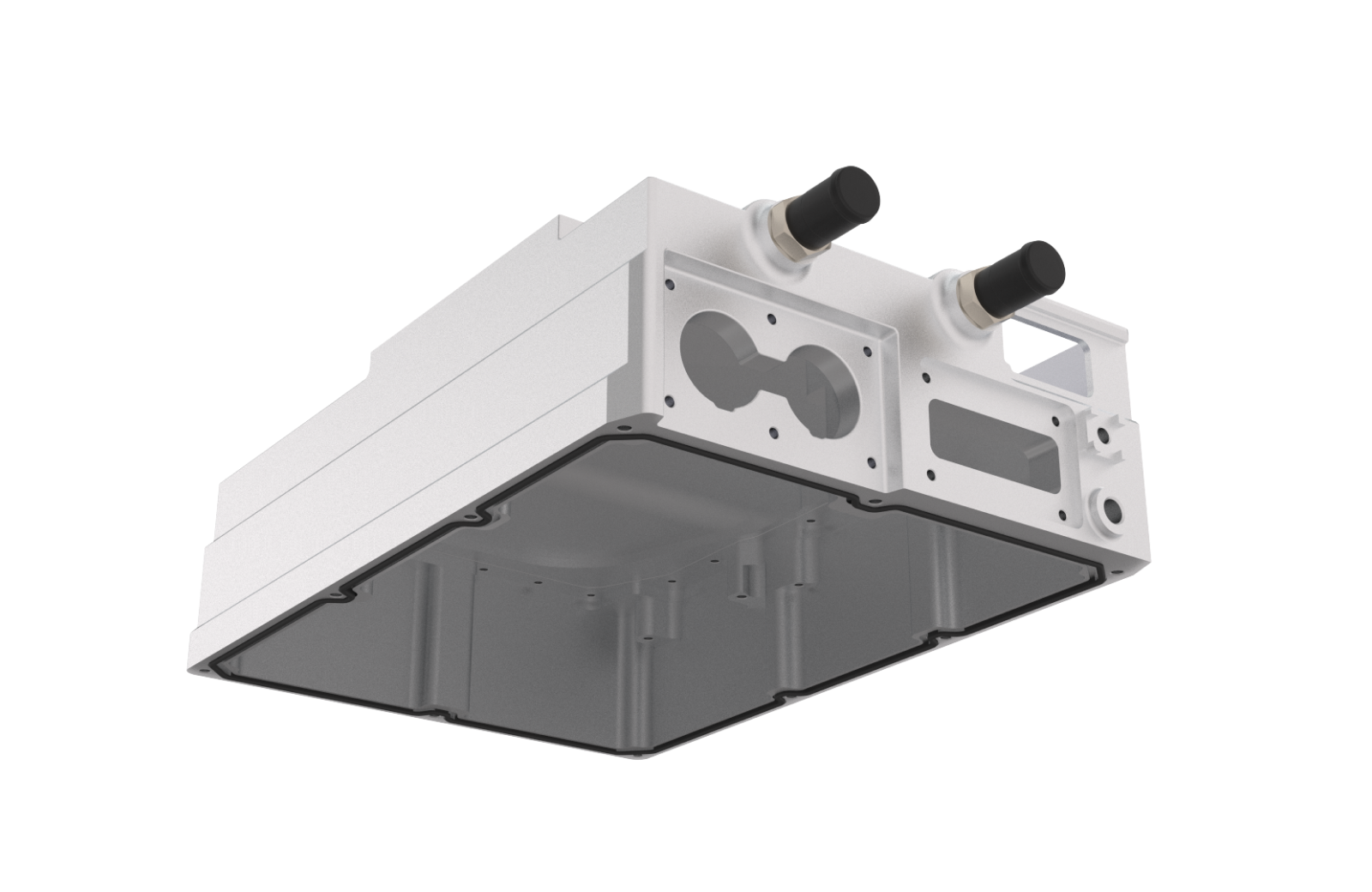

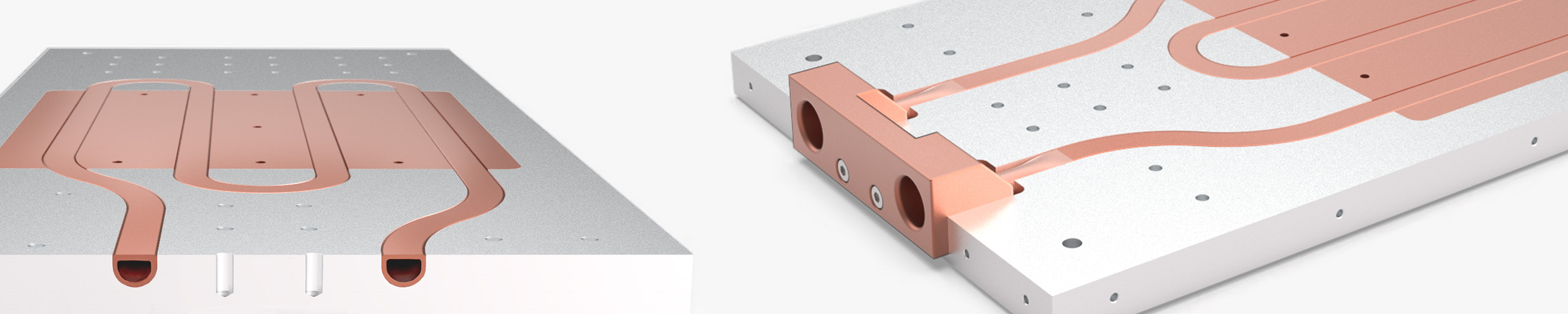

Embeddedflow combines housing protection with efficient liquid cooling. Precisely integrated structures dissipate heat directly, reduce hotspots, and ensure stable temperatures for electronic components.

Learn more in a conversationHardly any limits for your design

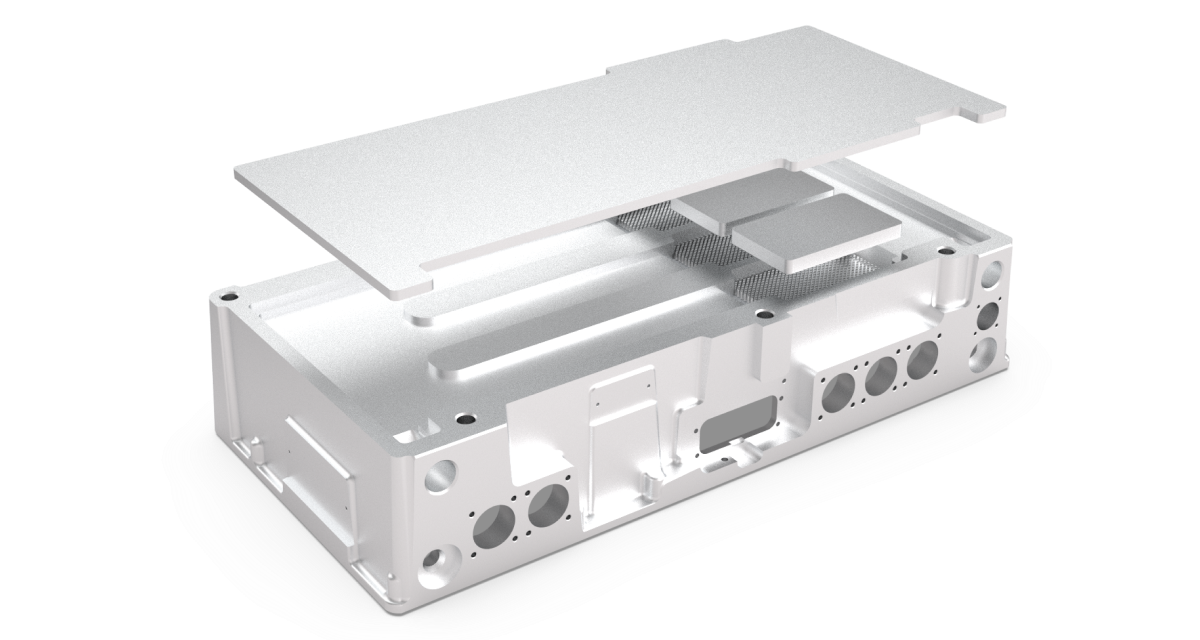

Implementation of all technically feasible solutions

Suitable method for every application

Options: friction stir welding, laser welding, vacuum brazing, bonding

Standard or custom connections

Internal or external, adaptable to any component integration

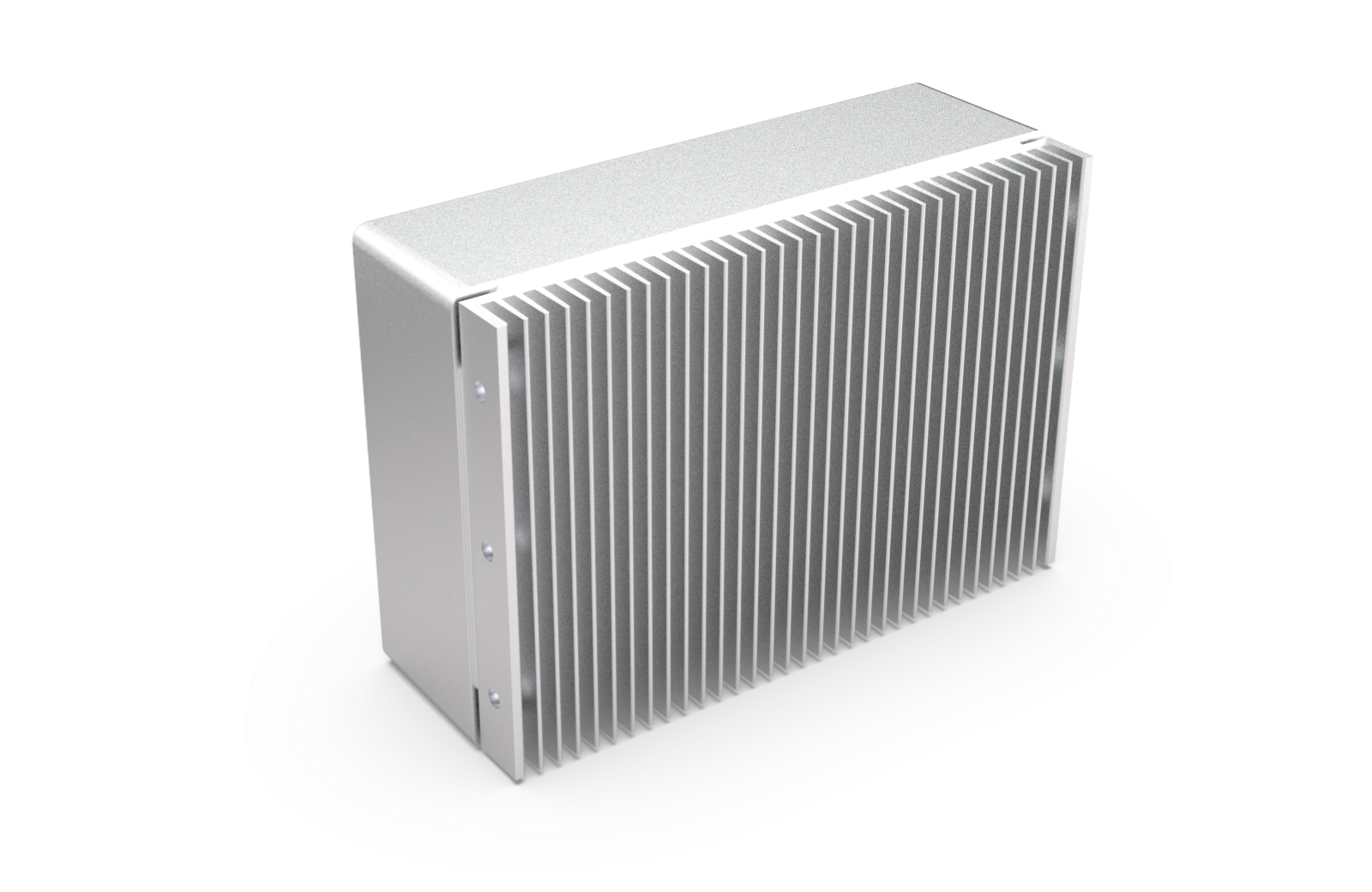

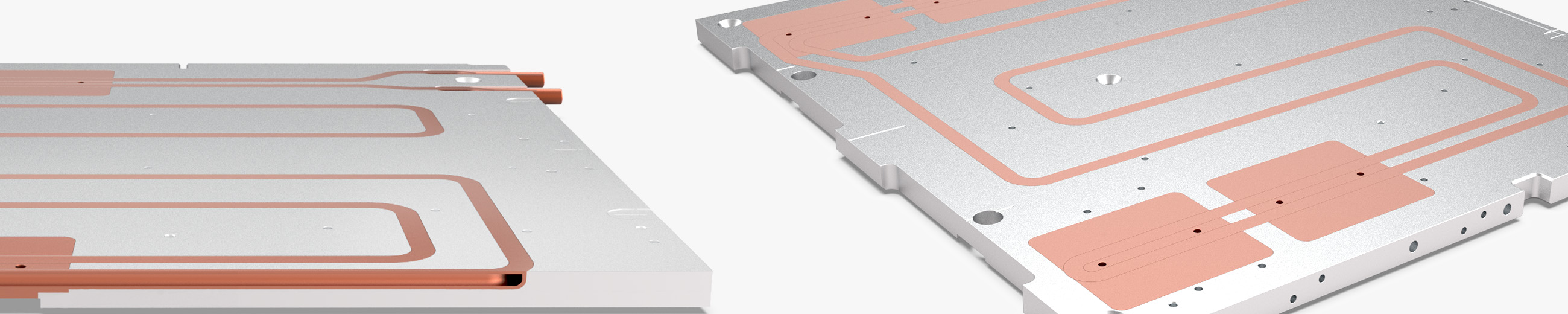

Housing heat sinks with or without fluid-carrying channels offer versatile solutions for effective heat dissipation in demanding applications.

Through customizable structures such as fins, ribs, or channels, the cooling performance can be perfectly adapted to the specific requirements. Depending on the design and application, the heat sinks are manufactured using precise methods such as brazing, welding, or bonding to ensure a reliable thermal connection. The flexible combination of internal structure and production technique ensures efficient heat dissipation, stable temperatures, and high cost-effectiveness.

Learn more in a conversation

Customizable fins, ribs, or channels for optimal cooling performance

Precise manufacturing methods: brazing, welding, or bonding

Versatile design possibilities for efficient heat dissipation

High efficiency, stable temperatures, and cost-effective solution

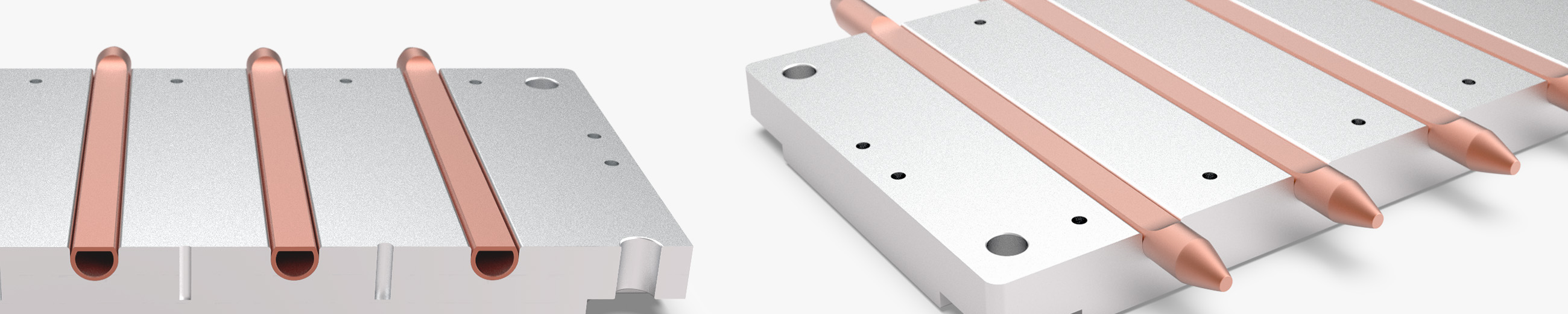

Fluid-carrying inserts made of copper or stainless steel conduct heat directly to the cooling medium, ensuring maximum thermal efficiency. They can be combined with milled or inserted structures to distribute heat evenly and reduce hotspots.

Copper inserts distribute heat across the entire cooling surface, stabilize operating temperatures, and extend the lifespan of sensitive electronic components. They are particularly effective when combined with fluid-carrying inserts or internal channel structures.

Heat pipes use phase change technology, where the liquid inside evaporates and condenses at cooler points. This allows heat to be transported efficiently, hotspots to be minimized, and stable temperatures to be maintained even in high-performance applications.

Digital thermal simulation enables fast analysis of existing designs and the development of new Embeddedflow solutions.

Optimized structures and channels ensure maximum cooling performance with minimal material usage.

With COOLTEC cooling solutions, you benefit from even heat distribution, reduced hotspots, and longer component lifespan.

Embeddedflow coolers are ideal when electronics must be both protected and cooled. They combine the function of a housing with integrated component cooling, offering maximum efficiency in compact applications.

Common materials include copper, aluminum, stainless steel, and special alloys. The choice depends on the thermal, mechanical, and fluid-related requirements of your application.

Milled or inserted structures such as channels, pins, ribs, or fins dissipate heat directly. They can be customized to reduce hotspots and adapt the cooling performance to your system requirements.

Depending on design and material, we use friction stir welding, laser welding, vacuum brazing, or bonding to ensure a secure and thermally efficient connection.

Standard and custom connections are available, both internal and external. Embeddedflow coolers can be flexibly integrated into complex system layouts.