E-Mobility

Learn how HV batteries, inverters, and power transistors are reliably cooled – compact, efficient, and perfectly tailored for your application.

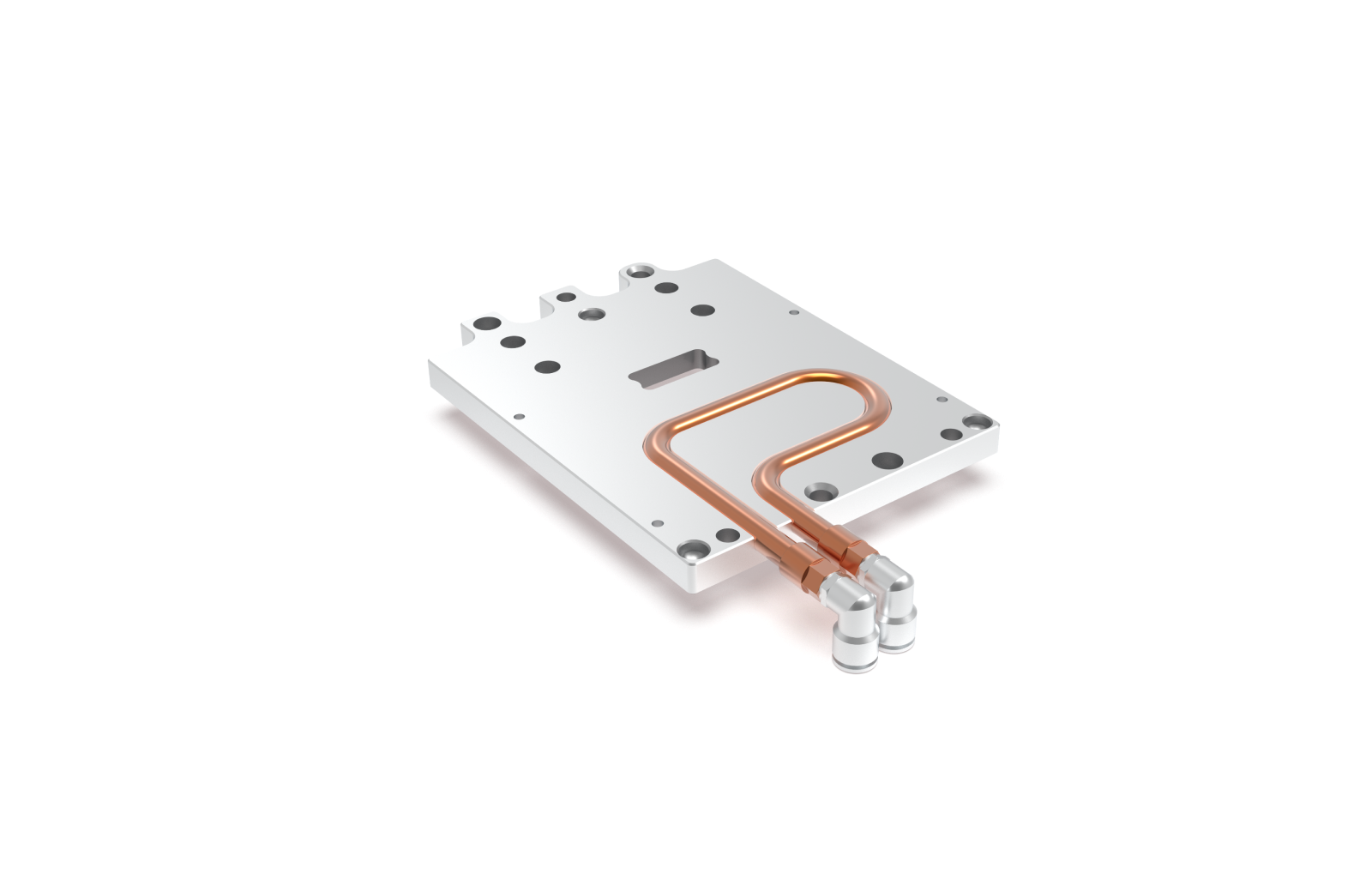

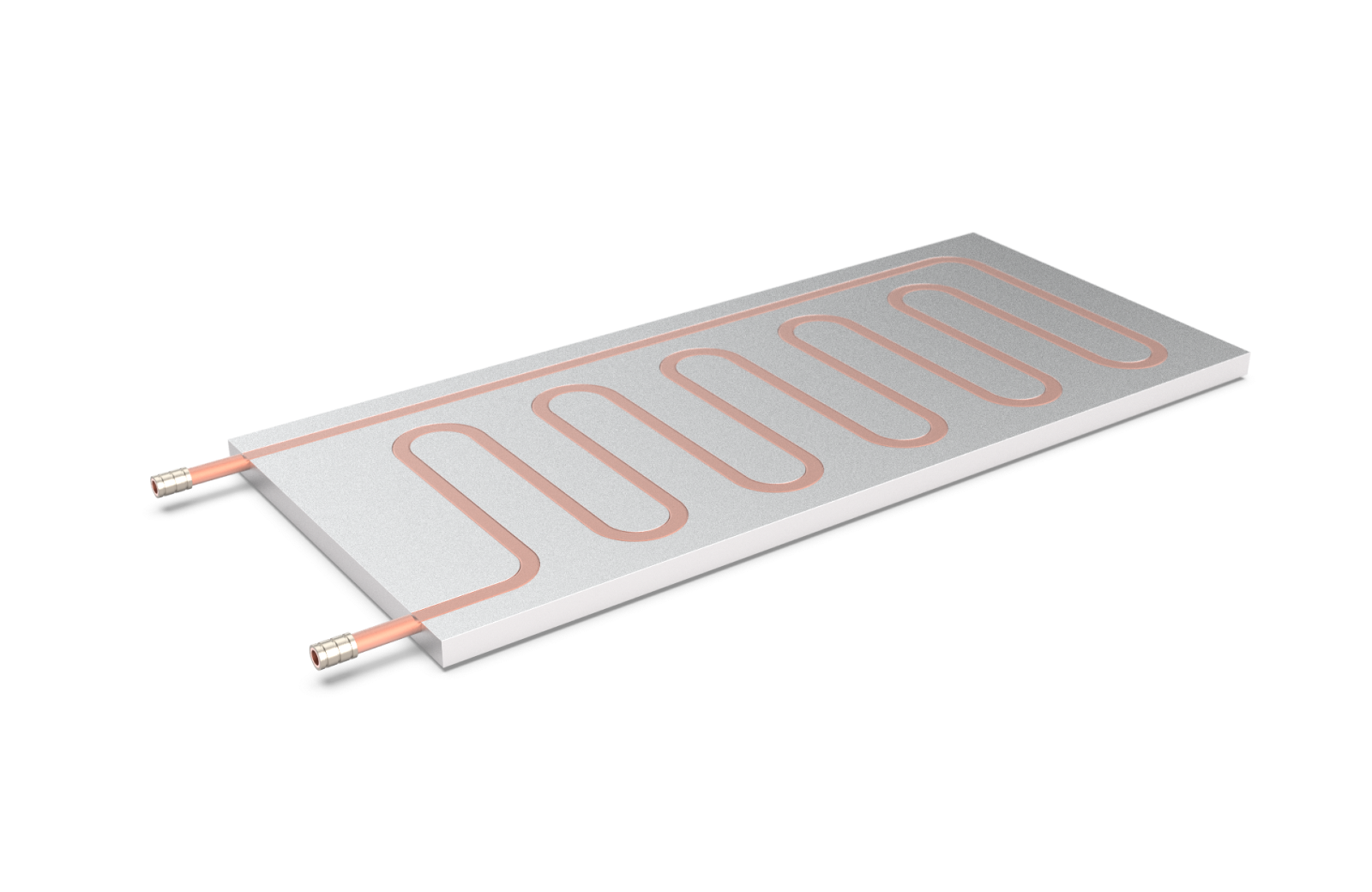

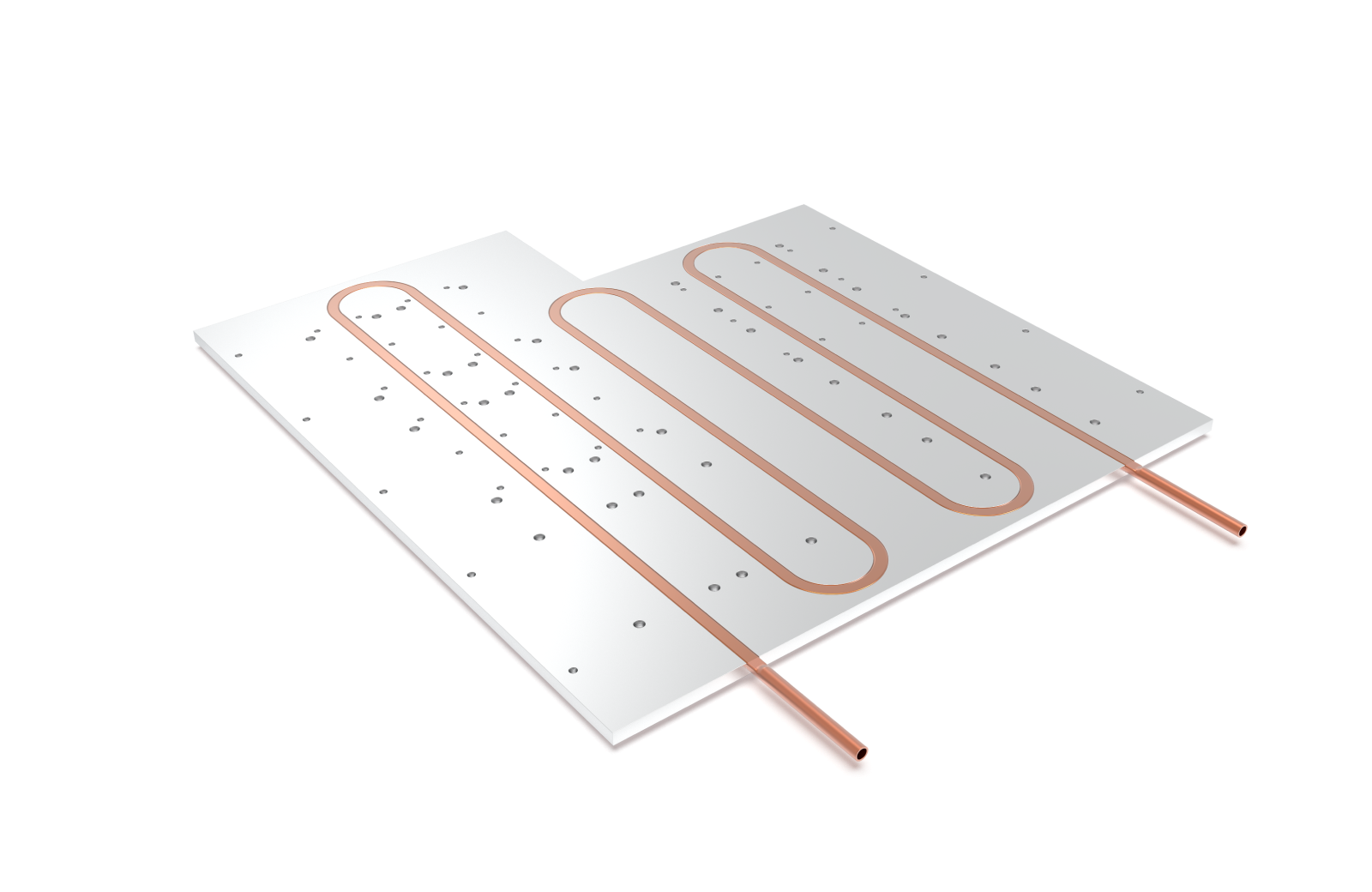

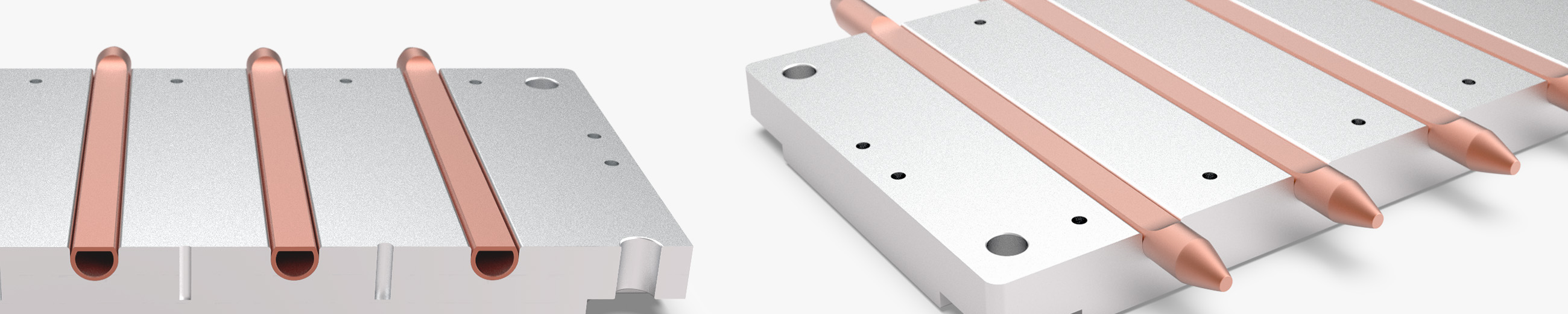

Efficient heat dissipation for high power losses. Copper, aluminum, or stainless-steel tubes ensure

maximum contact with the cooling medium – without any adhesive or foreign material.

Direct metallic contact between tube and plate

No adhesive, no foreign media → maximum thermal conductivity

Perfect flatness, no outgassing from foreign materials

Copper, aluminum, stainless steel, or special alloys such as copper-nickel

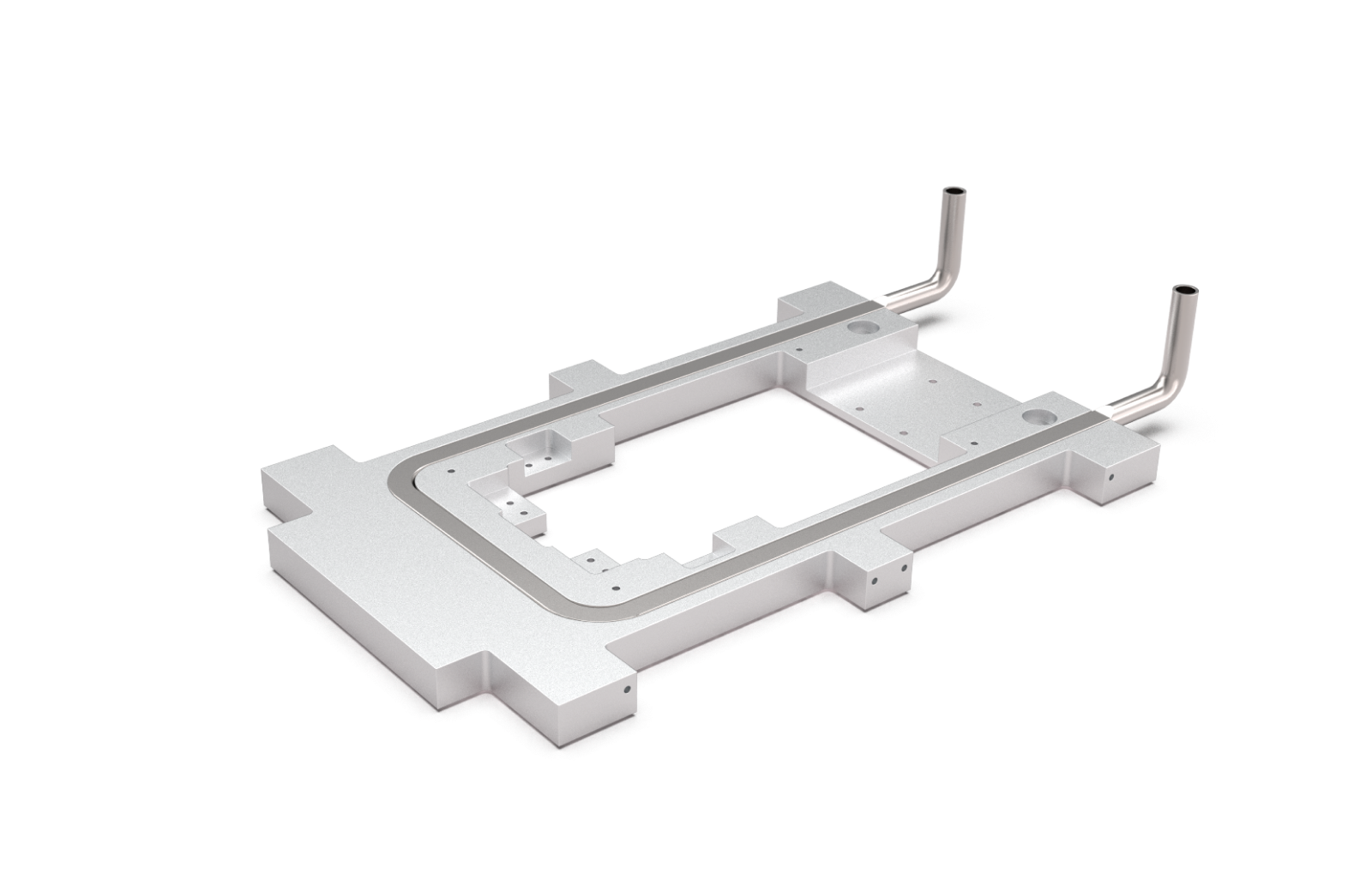

Precise press-fit technology for tight radii and flexible shaping

Ideal for high power density applications

Standard or custom connections

Internal or external, adaptable to any component integration

Compatible with various tube layouts and mounting designs

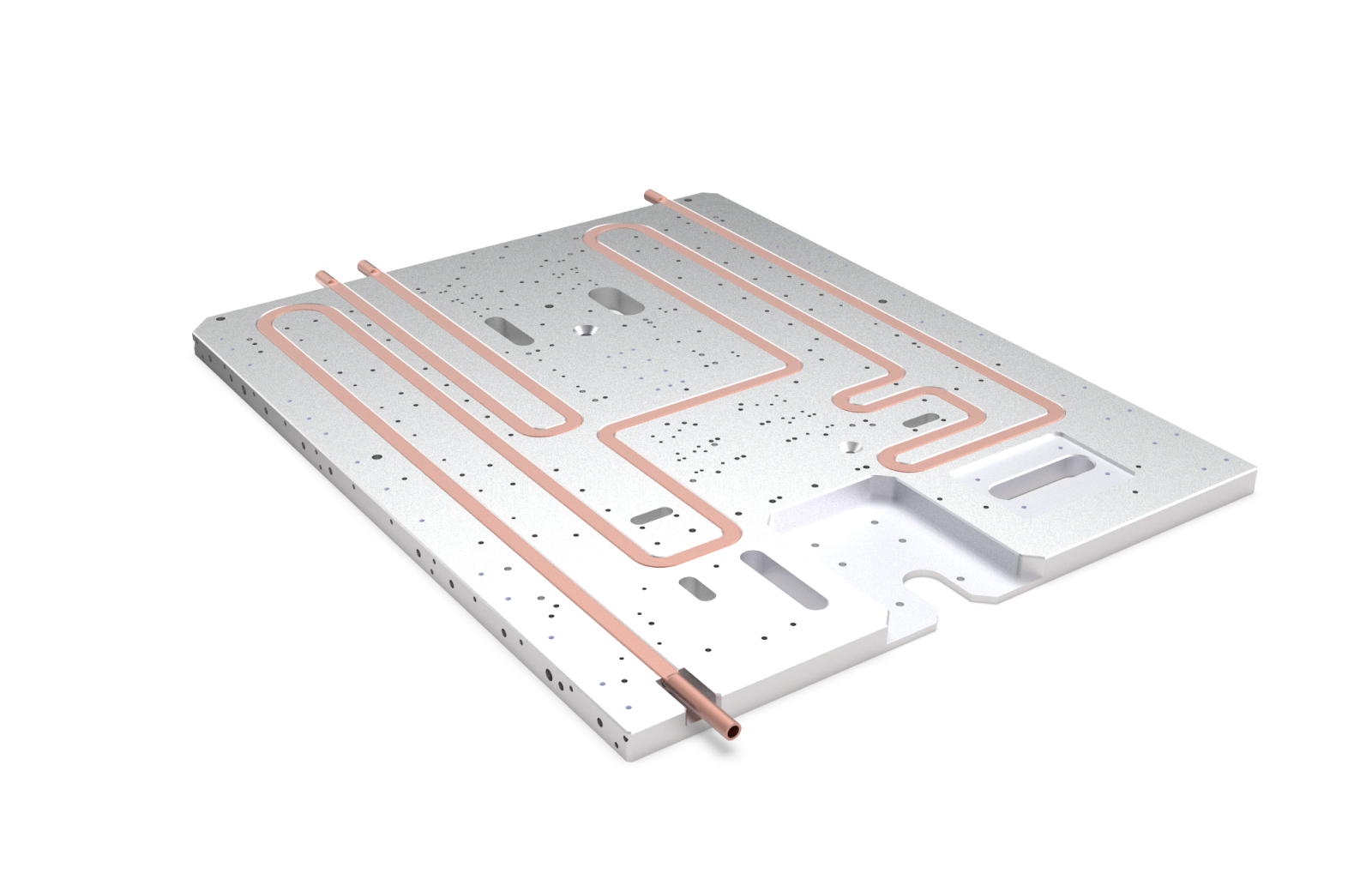

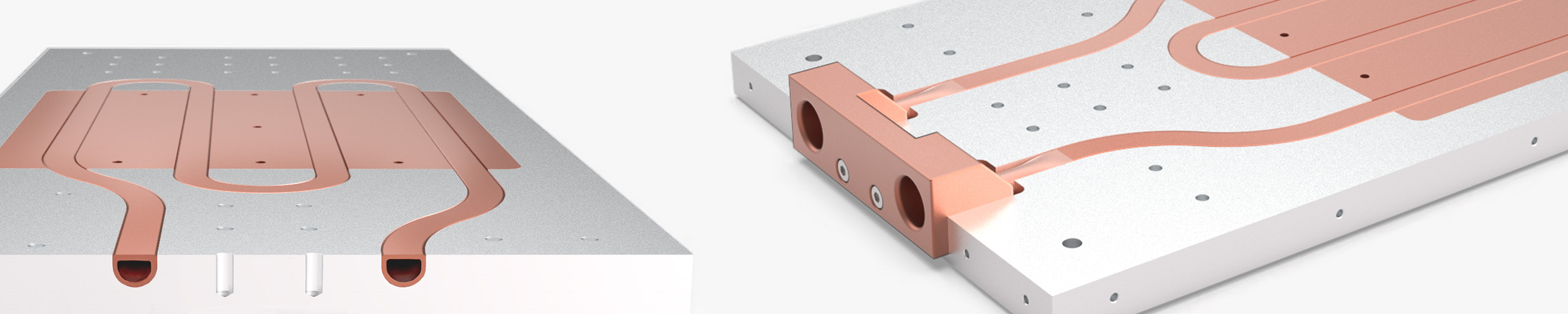

For liquid coolers with single-sided pressed-in tube or meander structures, the focus is on maximum thermal efficiency. This is achieved through optimally pressed-in tubes without gaps and precise mechanical processing.

Each cooling plate is designed so that heat is transferred directly and evenly from the components to the cooling medium.

Learn more in a consultation

Optimal press-fit technology: Tubes without adhesive or foreign materials → maximum heat transfer

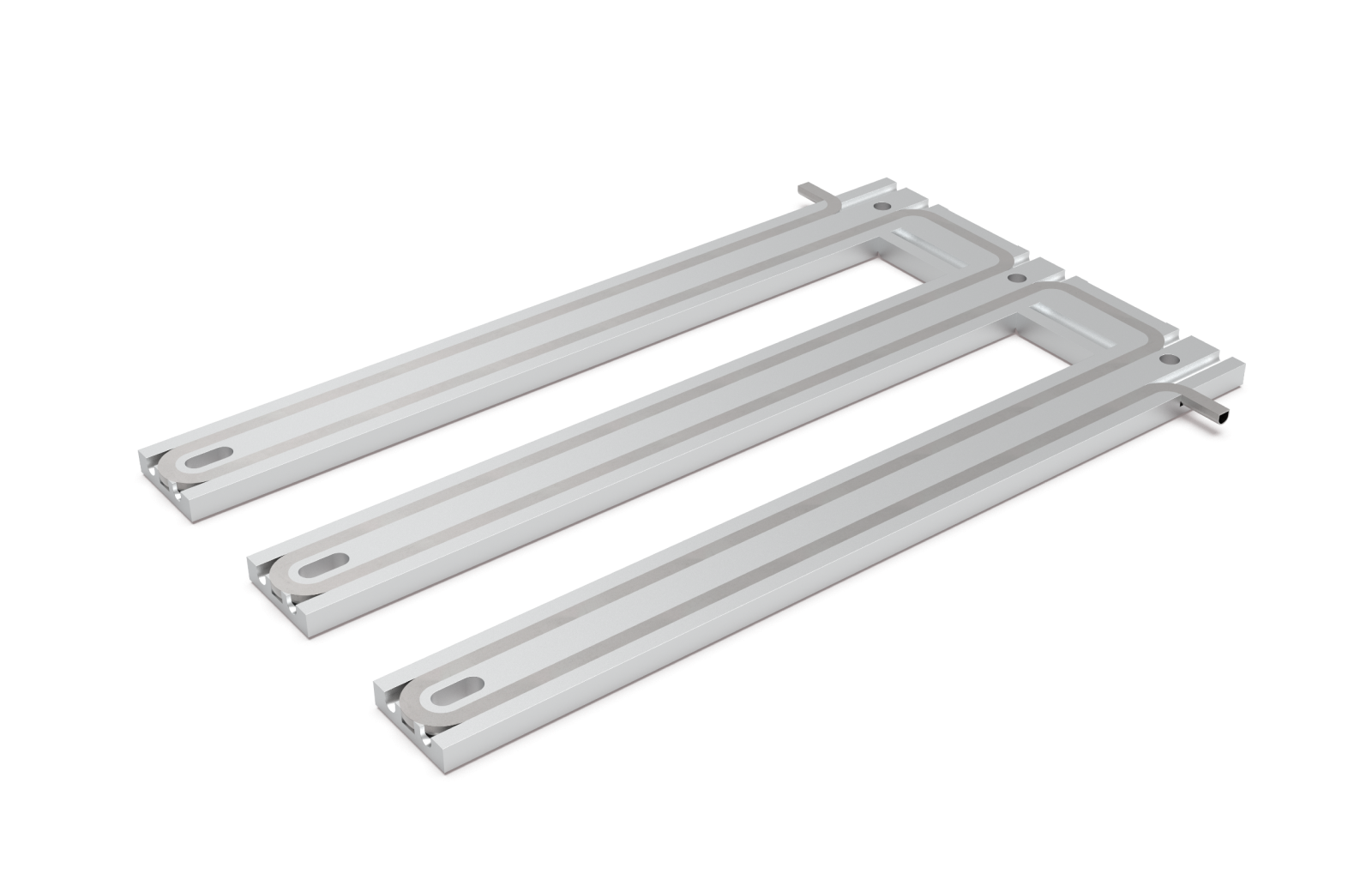

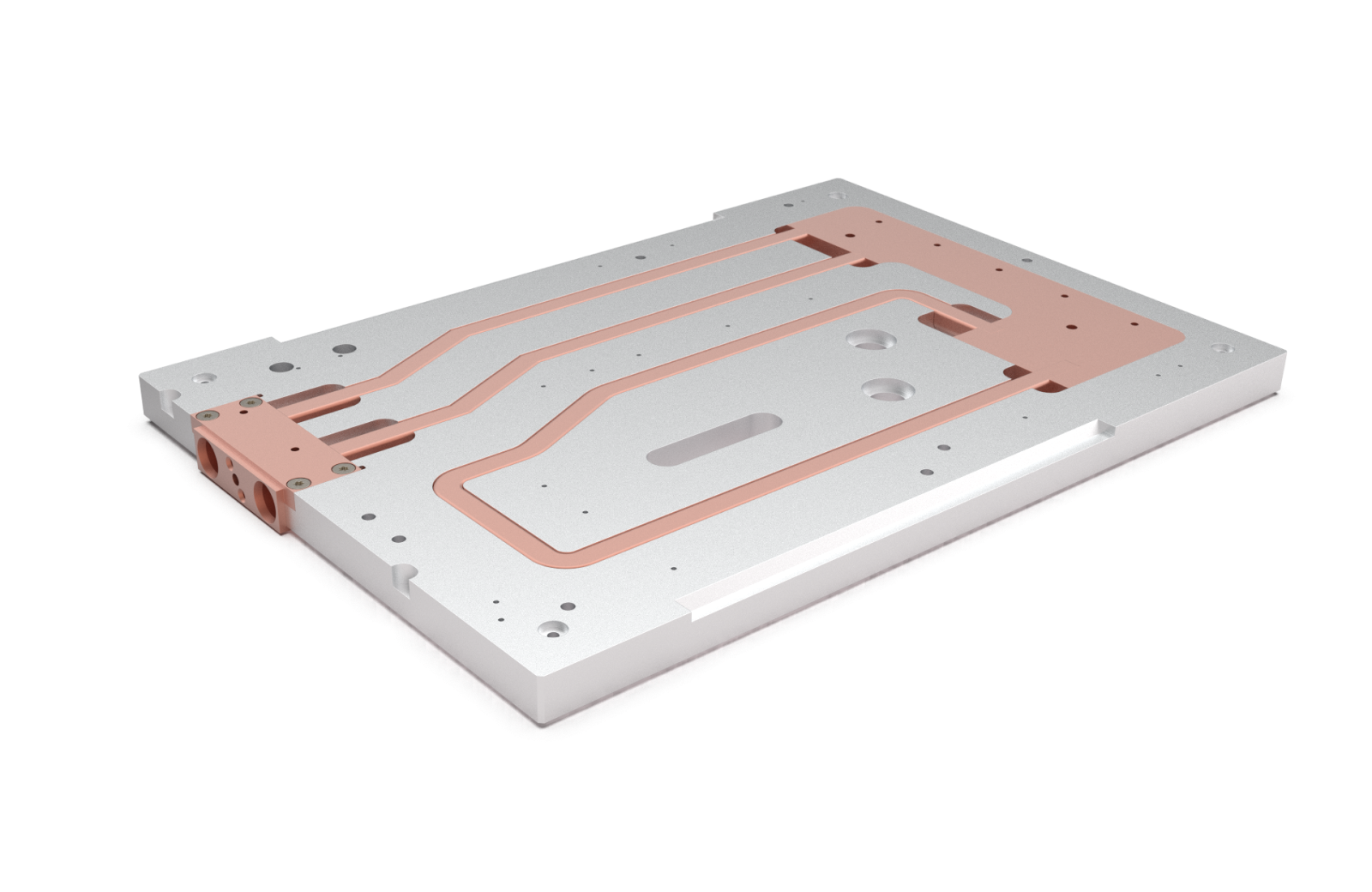

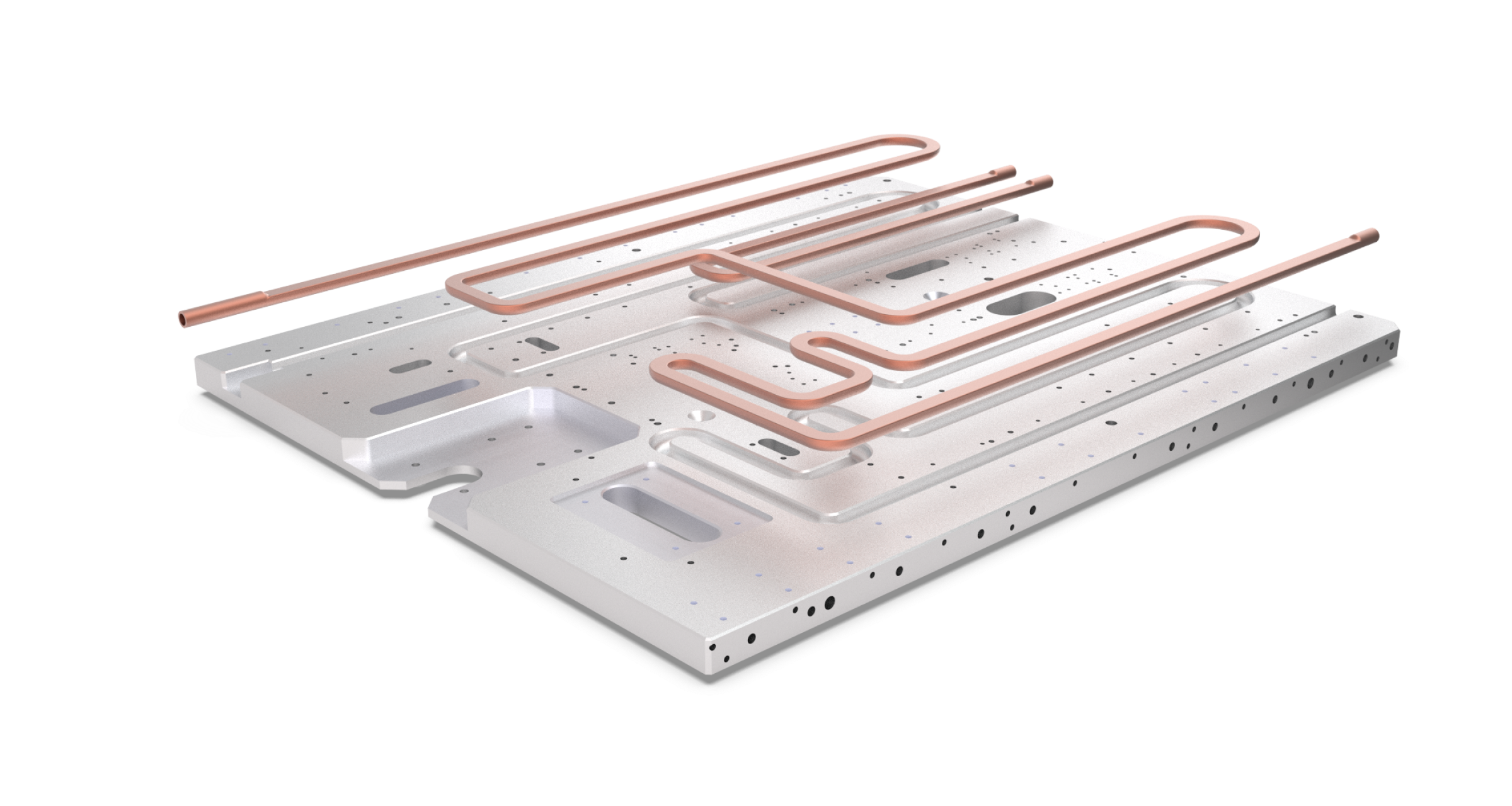

Flexible integration: Double-sided holes, custom fins, and connection options

Precision machining: CNC-milled flatness for perfect mounting fit

Tested reliability: Leak tests and tool breakage monitoring for safe, long-lasting cooling plates

High adaptability: Tight radii, complex tube layouts, and various materials (copper, aluminum, stainless steel, special alloys)

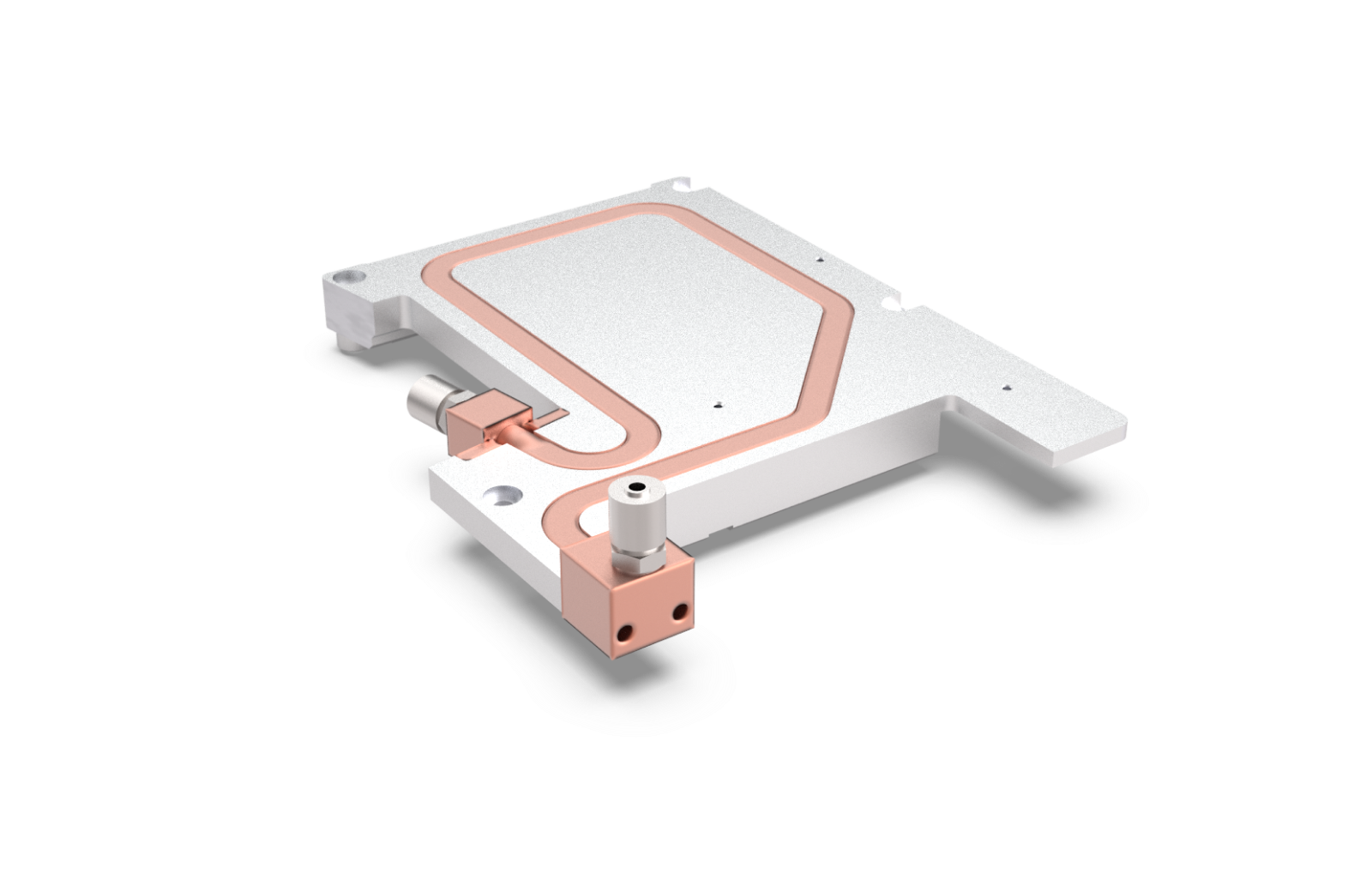

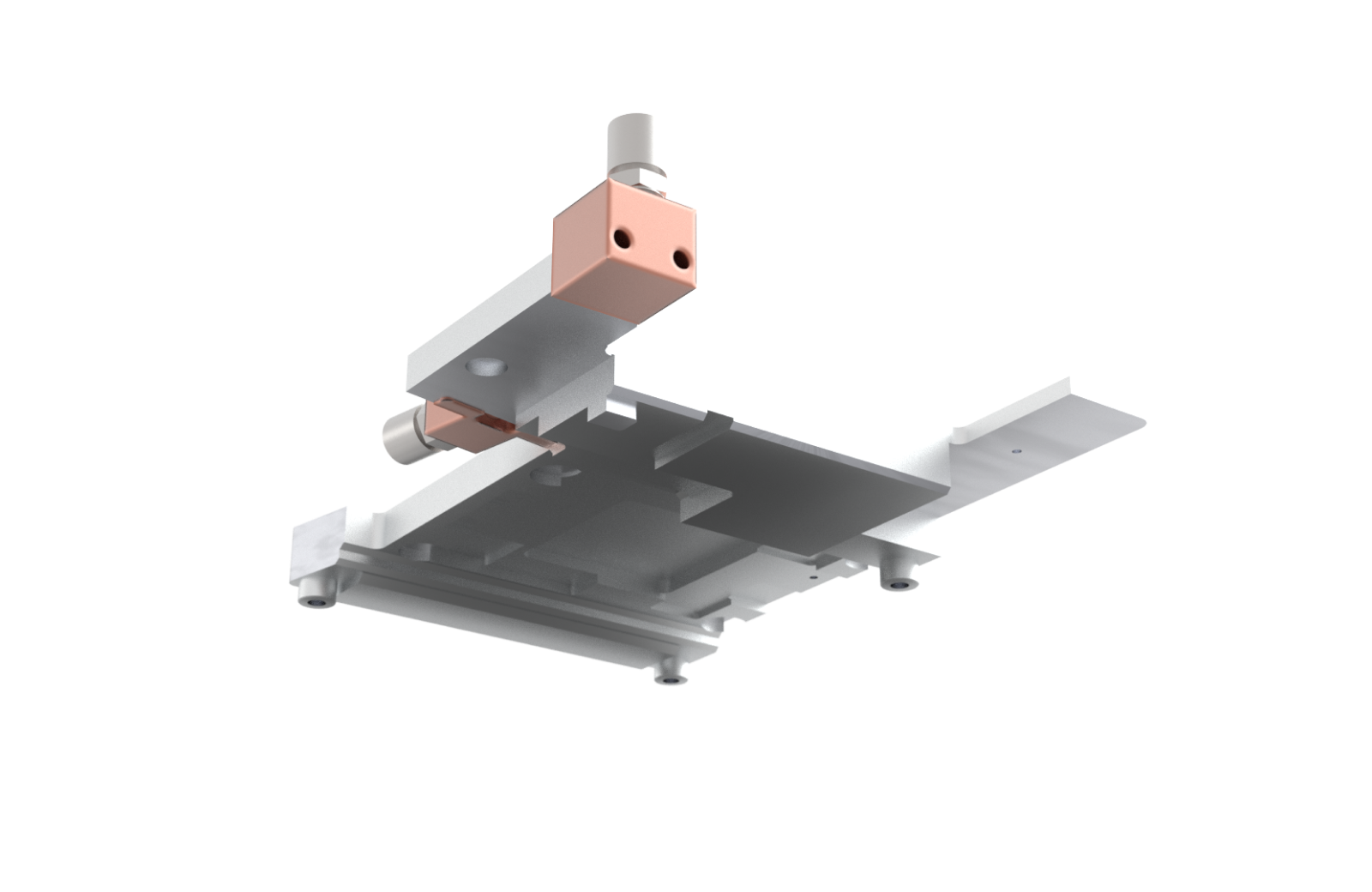

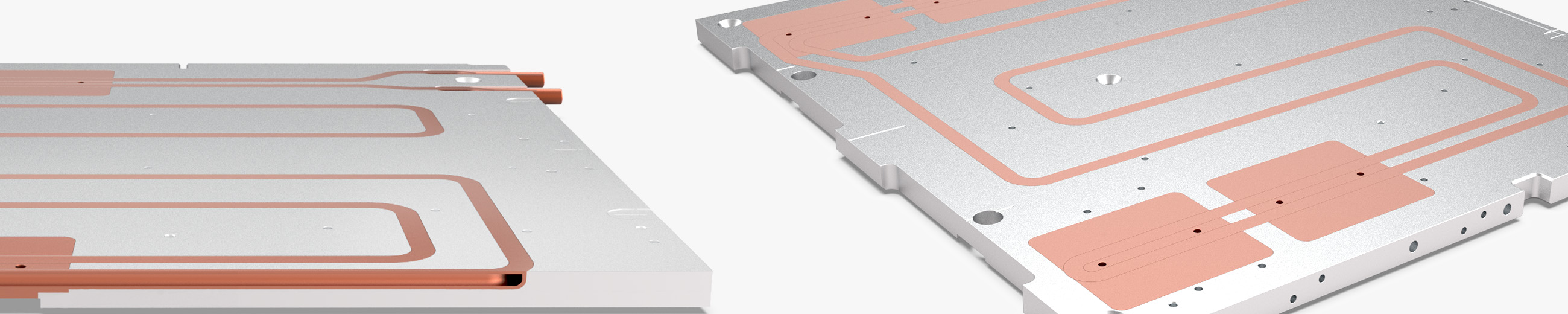

Copper or stainless-steel inserts transfer heat directly to the flowing cooling medium, enabling particularly efficient heat dissipation. Available in various materials and alloys, they can be easily combined with press-fitted tube systems to further boost thermal performance – ideal for high power densities and dynamic temperature profiles.

Embedded copper inserts evenly distribute heat across the cooling surface. Whether directly under the fluid channels or in other areas, they ensure stable operating temperatures, reduce hotspots, and extend the lifespan of sensitive components.

Integrated heat pipes use phase-change technology, where liquid evaporates and condenses at cooler points. This distributes heat efficiently, reduces hotspots, and ensures constant operating temperatures in high-performance applications.

COOLTEC’s digital thermal simulation enables fast, precise, and resource-efficient development of your cooling solution. Whether optimizing existing designs or creating new ones – we refine performance, material usage, and space for maximum cooling efficiency.

COOLTEC supports you in selecting, designing, and customizing your Monopress cooling solution – fast, efficient, and precise.

Monopress coolers are ideal for high power losses, limited space, or complex component layouts. Single-sided press-fitting transfers heat directly to the cooling medium without adhesives or foreign materials – for maximum efficiency and stability.

Copper, aluminium or stainless steel are used as standard; special alloys such as copper-nickel are also available on request. The choice of material has a decisive influence on thermal conductivity, weight, corrosion resistance and integration into the respective construction environment.

The tubes are mechanically pressed into the cooling plate with high precision, creating direct metallic contact, strong heat transfer, and perfect flatness – reducing hotspots and stabilizing temperatures.

In addition to Monopress technology, media-carrying inserts, copper inserts, or heat pipes can be integrated to enhance heat distribution and maintain stable operating temperatures.

Monopress cooling plates can be equipped with standard or customized connections, either internal or external, depending on your system requirements.

Thermal simulation, virtual testing, and customized designs ensure optimized Monopress cooling plates – powerful, material-efficient, and compact.