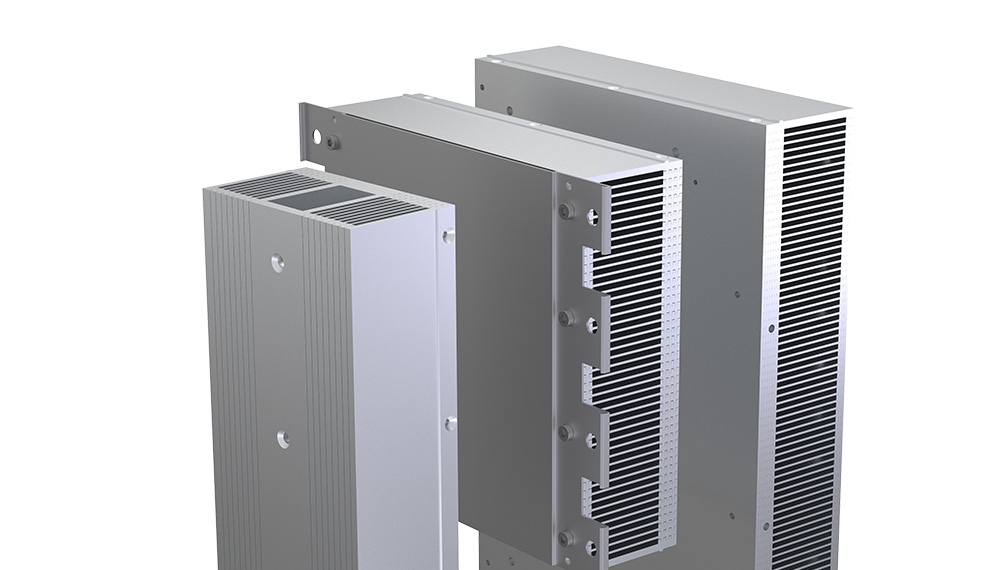

Side Pressed Fin Heat Sinks

Learn how our product family enables small fin spacing and dual-sided component mounting and cooling – for compact, high-performance cooling solutions.

We rely on precise forming and machining technologies such as punching, bending, and milling to shape alloyed metals into the desired form.

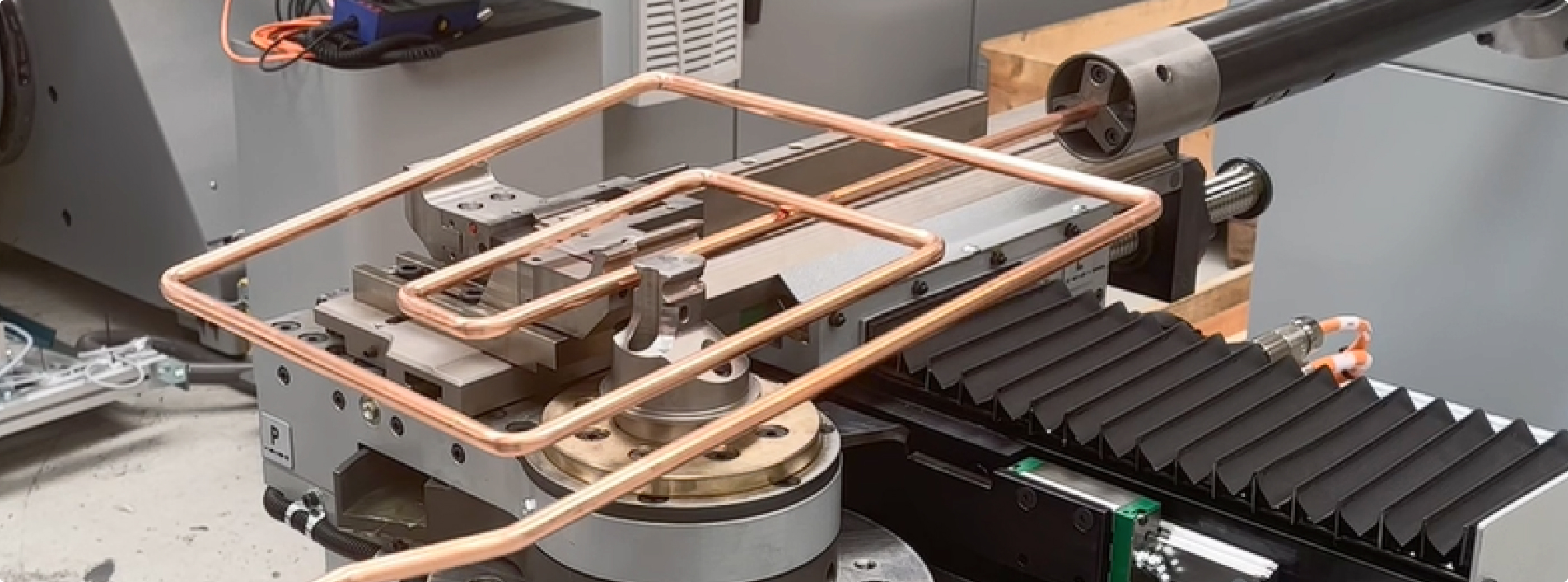

Tube bending is an essential process in the production of liquid coolers. Tubes made of copper, aluminum, or stainless steel are bent precisely to create complex cooling structures. Temperature, bending radius, and material strength must be optimally coordinated to ensure accurate shaping without cracking.

Learn more

CNC machining plays a key role in the high-precision production of air and liquid coolers. Only through CNC processing can raw materials become customized heat sinks with precisely defined geometries. The wide range of machining options allows for maximum precision, efficiency, and quality in production.

Learn moreOur experts work with you to develop the perfect machining and forming solution – customized, practical, and technically advanced. Every workpiece becomes a high-performance heat sink precisely tailored to your requirements.

Learn how to optimize cooling for high-tech applications – with solutions that are efficient, reliable, and ready to implement.

Download report