Welding

Learn how innovative welding techniques create permanent material bonds while optimizing stability, tightness, and heat transfer.

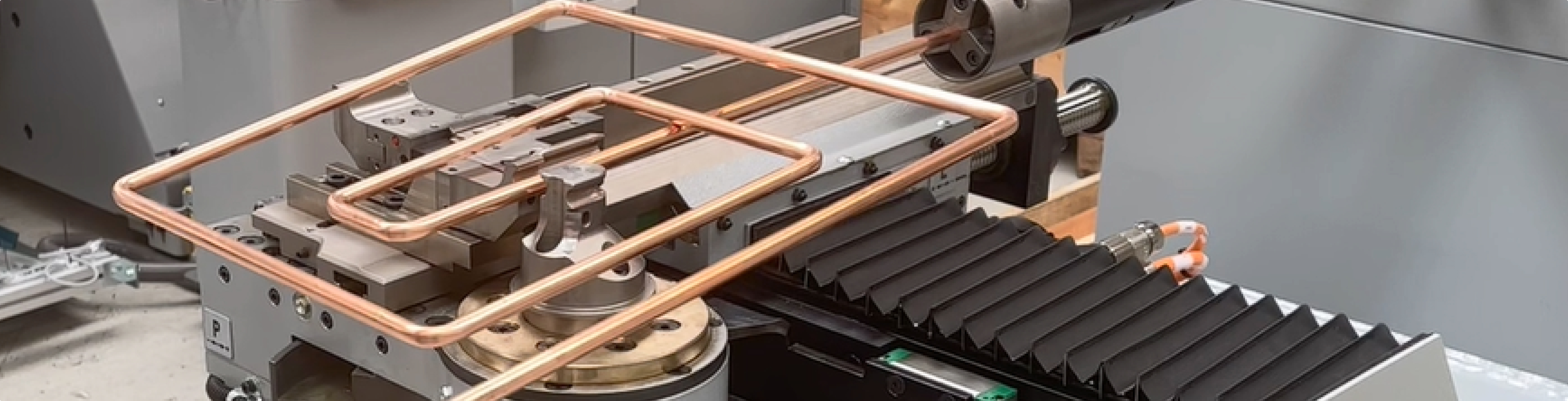

Tube bending is a key manufacturing step in producing modern liquid coolers and heat sinks. With precise bending technologies, copper, aluminum, and stainless-steel tubes can be shaped exactly to the required geometry, enabling compact, high-performance, and custom-configured cooling structures.

Learn more in a conversationWhether for prototypes, small batches, or series production – tube bending enables flexible, cost-efficient, and reproducible implementation of thermal systems in power electronics, e-mobility, and industrial cooling technology. In the bending process, a straight tube is formed into the desired shape using a CNC bending machine. Depending on the material, the tube is cold- or hot-formed to avoid deformation or thinning.

The use of precise mandrel and roll bending machines allows for tight bending radii, consistent wall thicknesses, and high repeat accuracy.

High precision: CNC-controlled manufacturing for exact geometries

Shape stability: No wrinkling or cross-section deformation

Reproducibility: Consistent quality in serial production

Flexibility: Adaptable to various tube diameters and radii

Cost efficiency: Fast, material-saving production process

Copper is the preferred material for liquid coolers, offering excellent thermal conductivity and superior bendability.

Very good forming properties

Tight radii achievable without cracking

High thermal performance

Ideal for high-performance applications in power electronics

Learn more about copper

Aluminum offers an optimal balance of weight, thermal conductivity, and corrosion resistance. It is ideal for applications focused on weight reduction and cost efficiency.

Low weight

Good heat transfer

Corrosion resistant

Cost-effective alternative to copper

Stainless steel is used where high chemical resistance and pressure strength are required – for example, in industrial cooling systems or special applications.

High stability and tightness

Good bendability with suitable machinery

Lower thermal conductivity than copper or aluminum

With state-of-the-art CNC technology, we produce precisely bent copper, aluminum, and stainless-steel tubes – for optimal heat transfer and perfect fit.