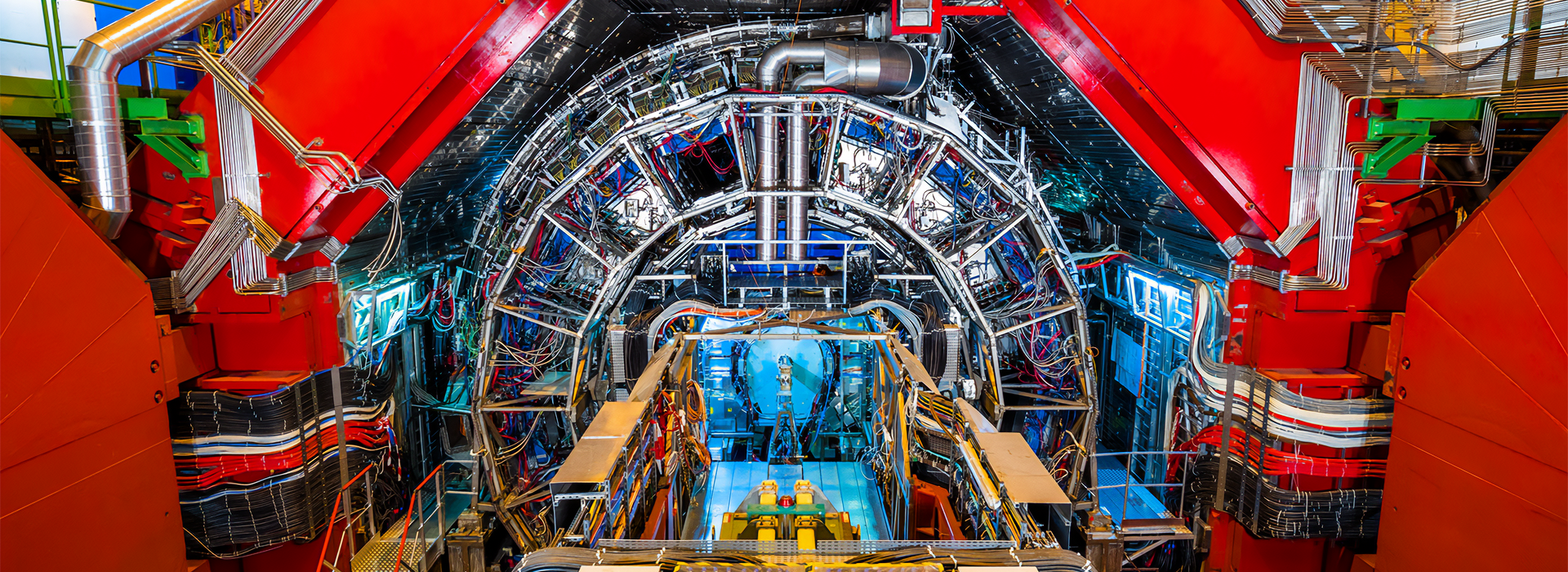

High-Frequency Technology: Precision Cooling for Maximum Signal Stability

Whether in transmitters, amplifiers, or RF power components – COOLTEC cooling solutions ensure reliable thermal management even under extreme operating conditions.

Why Cooling in High-Frequency Technology Is Essential

Electronic components in high-frequency systems face intense thermal loads. Without proper cooling, performance degradation, interference, and permanent damage can occur – directly impacting reliability, efficiency, and system lifespan.

Our cooling systems ensure stable temperatures, maximum performance, energy efficiency, and minimized downtime and maintenance.

Learn more in a conversationWithout Targeted Cooling, You Risk:

Overheating of amplifiers, oscillators, and RF components – performance loss and signal distortion

Shortened component lifespan

Reduced signal quality and system reliability

Increased maintenance and energy consumption

COOLTEC Solutions for High-Frequency Technology

With COOLTEC, you benefit from cooling systems designed specifically for high-frequency applications. Our solutions ensure stable temperatures and maximum performance even under high frequencies, intensive signal processing, and compact designs.

Maximum signal stability within the same footprint

Stable temperatures under continuous and extreme conditions

Reduced downtime and maintenance effort

Improved energy efficiency through optimized thermal management

Top Performance for Your High-Frequency Systems

Our cooling solutions keep your RF components reliably at operating temperature. Fewer failures, optimized performance, and long-lasting systems – from early development to full production.

Frequently Asked Questions

RF components generate significant heat at high voltages and frequencies. Without cooling, performance loss, interference, and permanent damage occur, critically affecting reliability and signal quality.

COOLTEC employs modular high-performance coolers, liquid cooling, thermoelectric coolers, and efficient heat exchangers – specifically developed for RF components, transmitters, and oscillators.

Yes, our systems are flexibly configurable and tailored to high-frequency application needs – from individual devices to mass production.

Developers achieve optimal temperature control for maximum signal stability, design freedom, and longer component life. Buyers benefit from competitive pricing, reliable delivery, and reduced maintenance costs.

- Stable temperatures even under continuous operation and high frequencies

- Reduced downtime and maintenance costs

- Maximum signal quality and system stability

- Energy-efficient thermal management

Get your Cool How Report 2026 now

Efficient thermal management for the high-tech industry

Learn how to optimize cooling for high-tech applications – with solutions that are efficient, reliable, and ready to implement.

Download report