Heating and Air Conditioning Technology

Heating and air conditioning technology is an essential industry that ensures comfort and energy efficiency in residential and commercial buildings. (...)

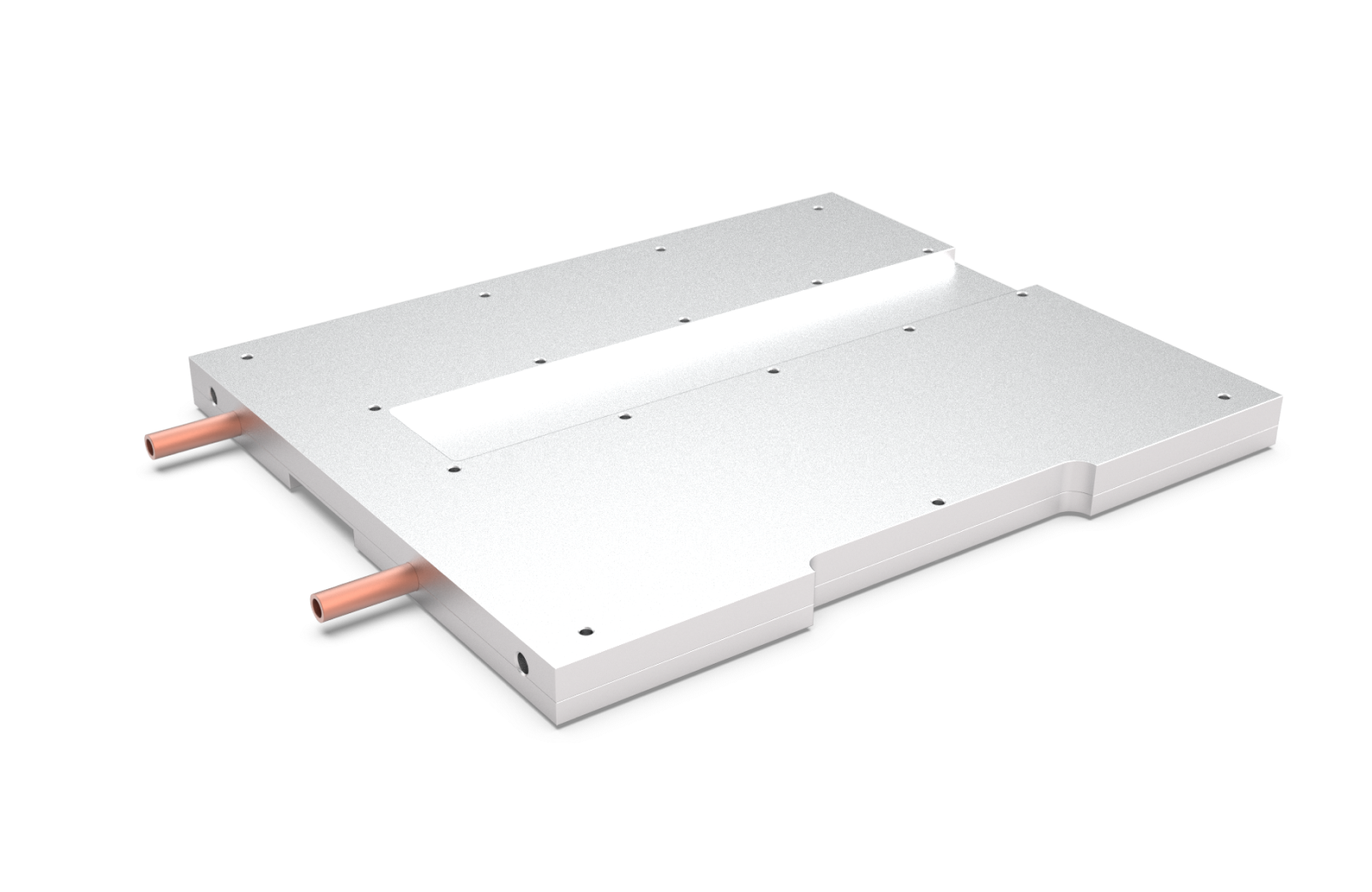

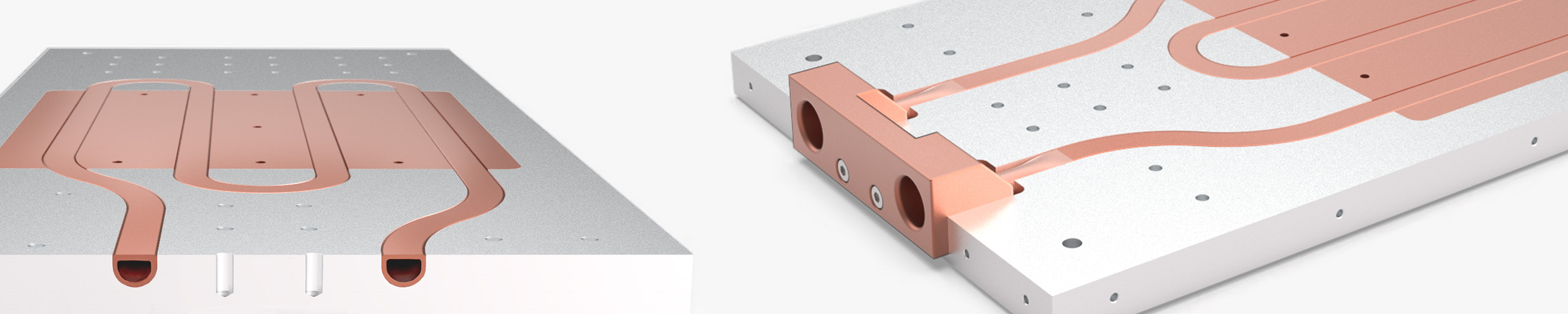

Efficient dual-sided cooling thanks to internal tubing for even heat dissipation.

Learn more in a conversationIdeal for applications requiring component cooling on both sides

Only one internal tube required – no tubing on both sides needed

Copper, aluminum, stainless steel or special alloys such as cupronickel

Precise press-fit technology allows tight radii and flexible layouts

Standard or custom connection options

Can be mounted internally or externally

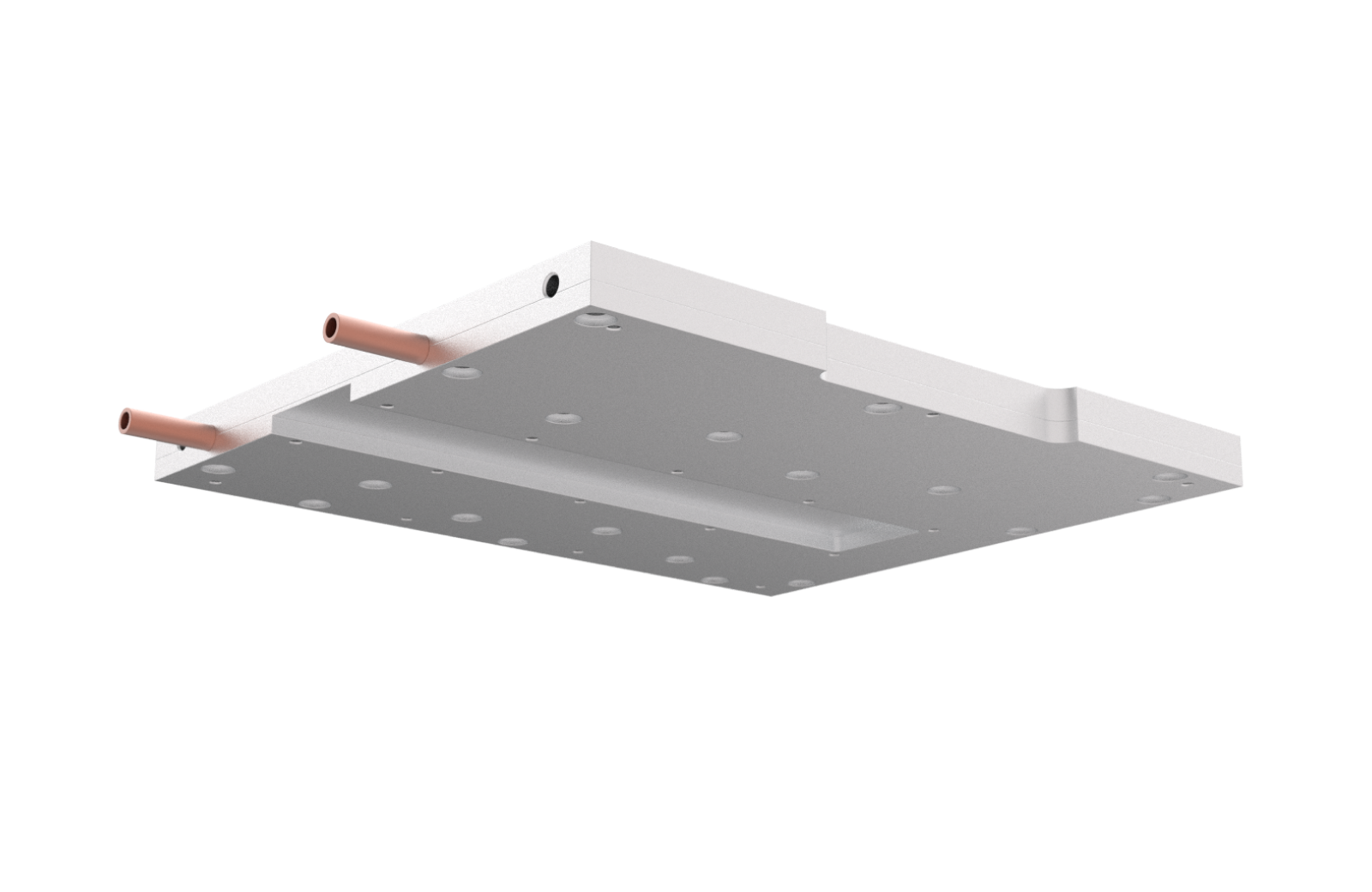

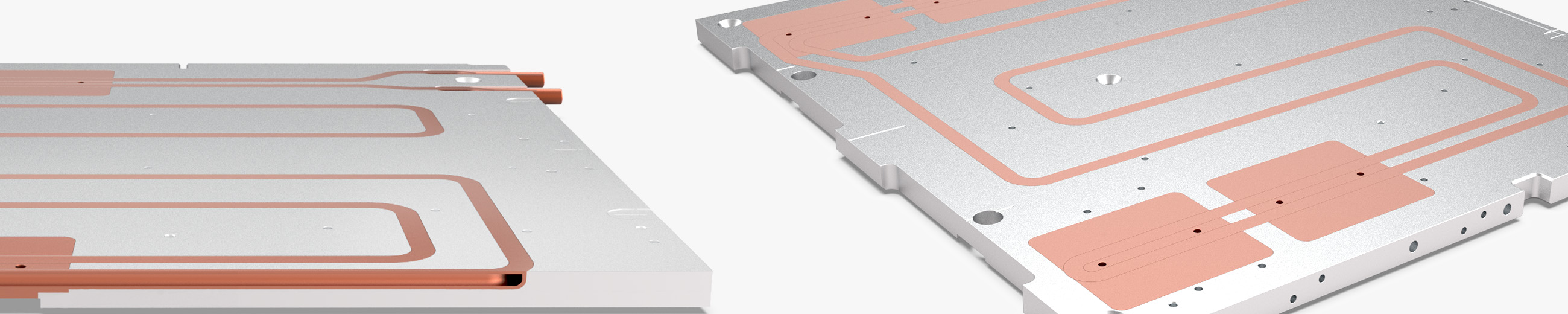

Internal tube structures ensure maximum thermal efficiency and even heat dissipation. The tubes are integrated precisely without gaps, ensuring reliable dual-sided component cooling.

High flatness ensures exact fit, easy assembly, and high reliability. Modern leak and tool-breakage tests minimize quality risks and guarantee consistent performance.

Learn more in a conversation

Uniform dual-sided component cooling

Optimal heat transfer without gaps

Precise flatness for easy assembly and high reliability

Quality assured through leak and tool integrity testing

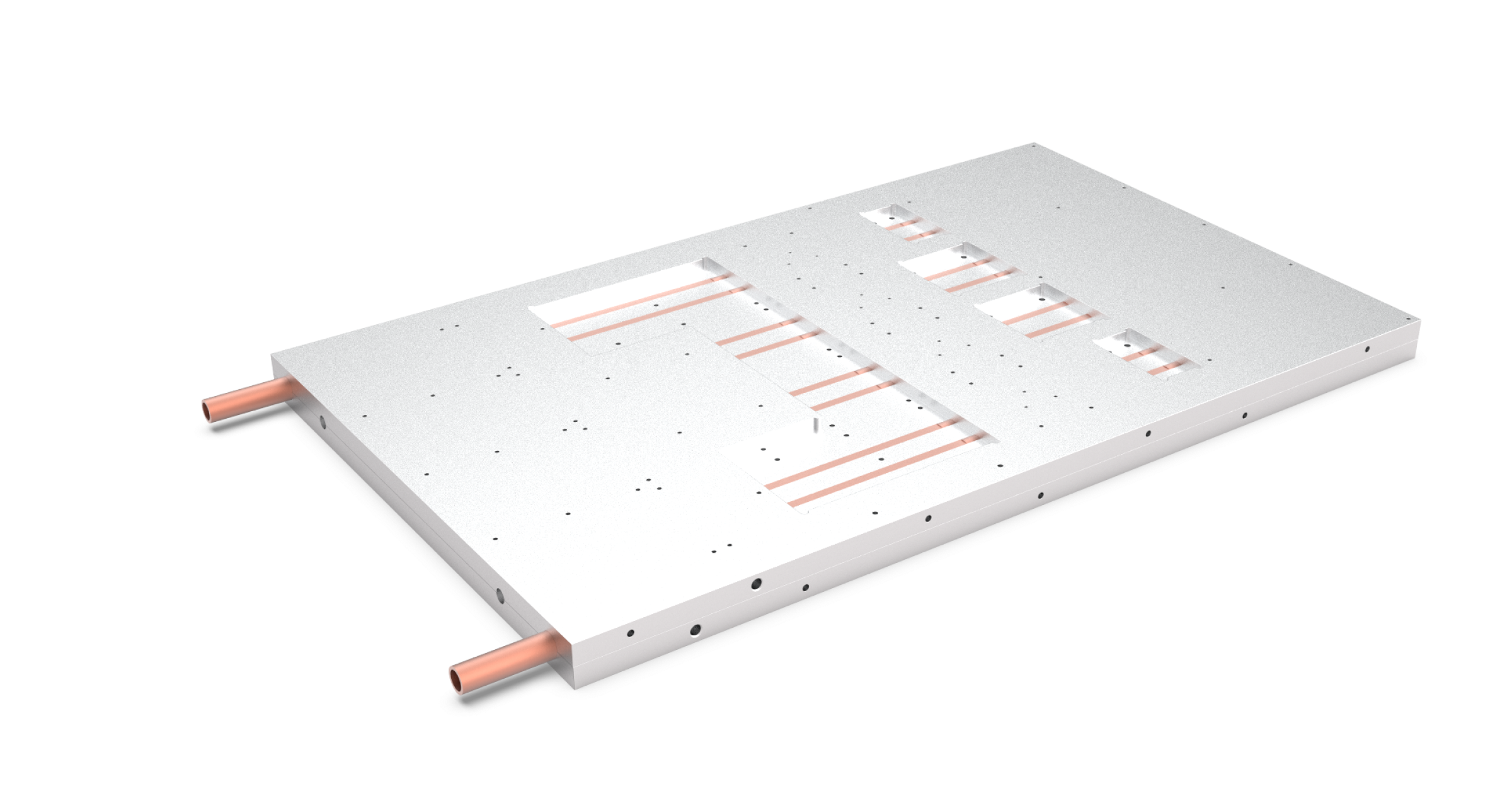

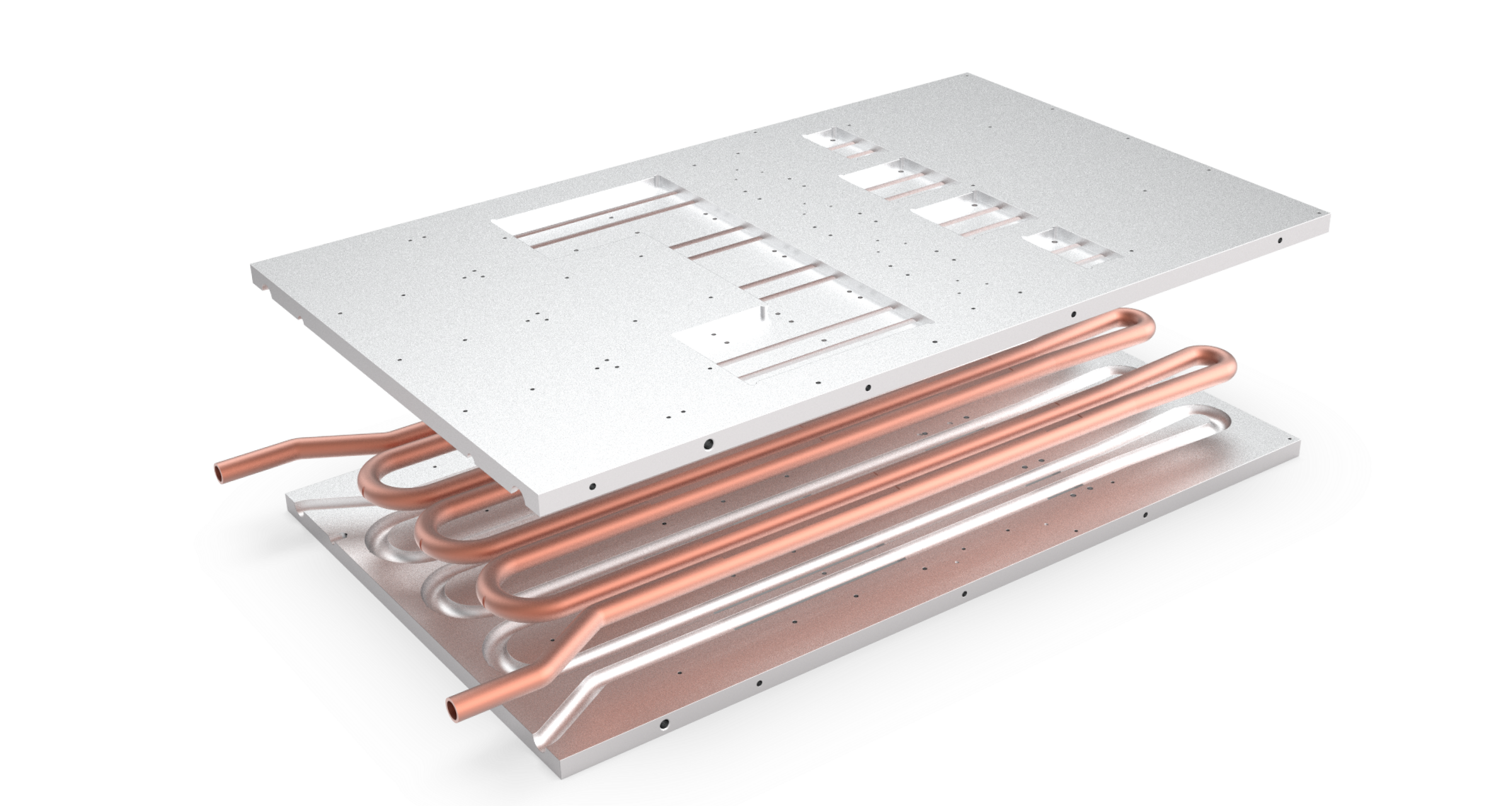

Copper or stainless steel inserts transfer heat directly to the flowing coolant, enabling highly efficient heat removal. Available in various materials and alloys, they can be easily combined with press-fitted tube systems to further enhance thermal performance.

Embedded copper inserts distribute generated heat evenly across the cooling surface. Whether placed directly under fluid channels or in other regions, they provide stable operating temperatures, reduce hotspots, and extend the lifetime of sensitive components.

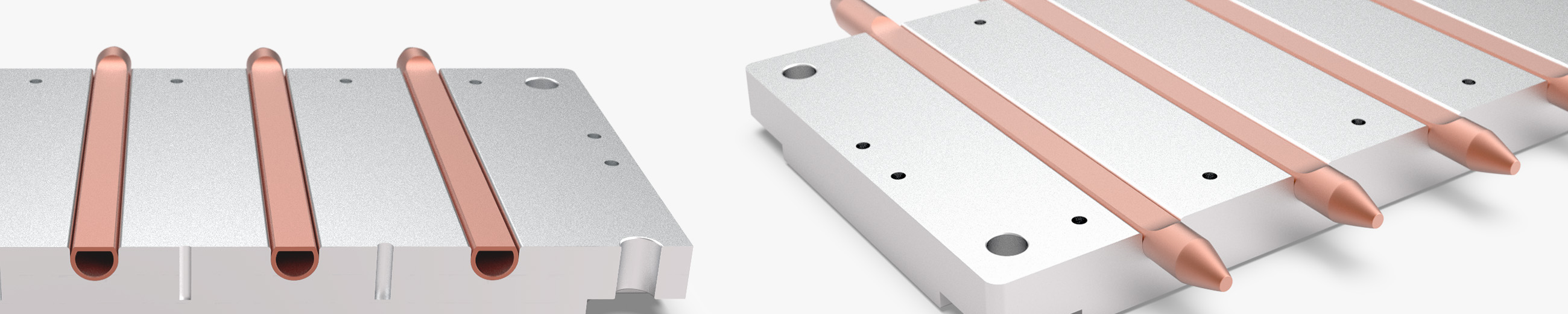

Integrated heat pipes use phase-change technology, where a liquid evaporates and condenses at cooler spots. This efficiently distributes heat, reduces hotspots, and ensures constant operating temperatures in high-performance applications.

COOLTEC’s digital thermal simulation enables fast, precise, and resource-efficient development of your cooling solution.

Whether analyzing existing designs or creating a new one, we optimize performance, material use, and space for maximum cooling efficiency.

Whether for high-performance electronics or compact designs: we develop cooling systems that combine performance and reliability – fast, precise, and customized.

Interpress coolers are ideal when components must be cooled on both sides. The internal tube ensures even heat dissipation, stable temperatures, and maximum efficiency.

Copper, aluminum, or stainless steel are used as standard. Special alloys such as cupronickel are available. The choice of material affects thermal conductivity, weight, corrosion resistance, and compatibility with the coolant.

The tubes are internally integrated into the cooling plate without gaps or adhesives, ensuring direct metallic contact with the cooling medium for optimal heat transfer.

Cooling performance can be enhanced through fluid-carrying inserts, copper heat spreaders, or integrated heat pipes. Thermal simulations help optimize tube layout, flow, and geometry for maximum efficiency.

Standard and customized connections are possible, mounted internally or externally. Front-mounted water distributors ensure even flow across all channels in complex systems.