Shipping and Marine

Discover how efficient cooling in motors, control systems, and power supply units enhances safety and performance at sea.

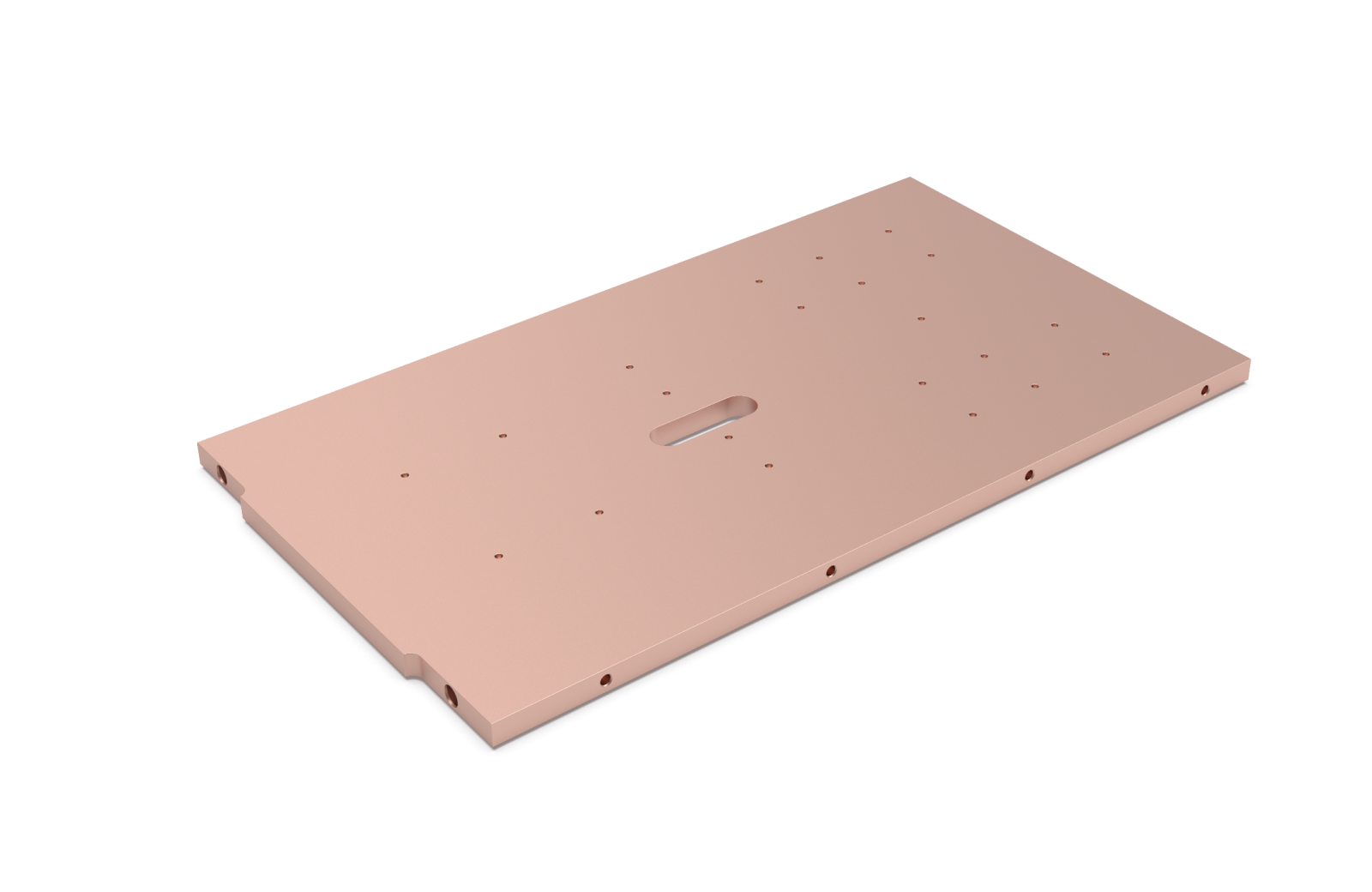

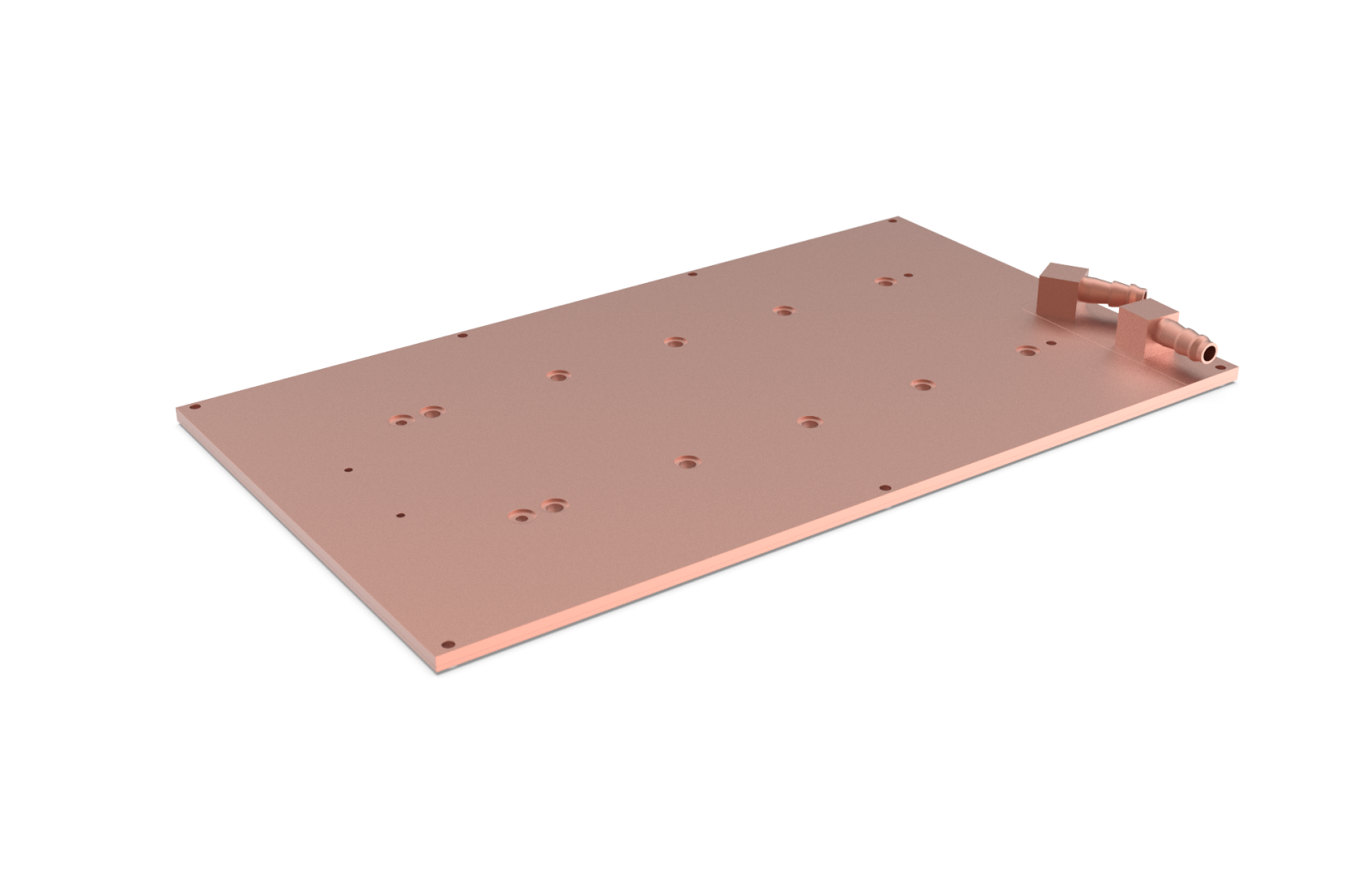

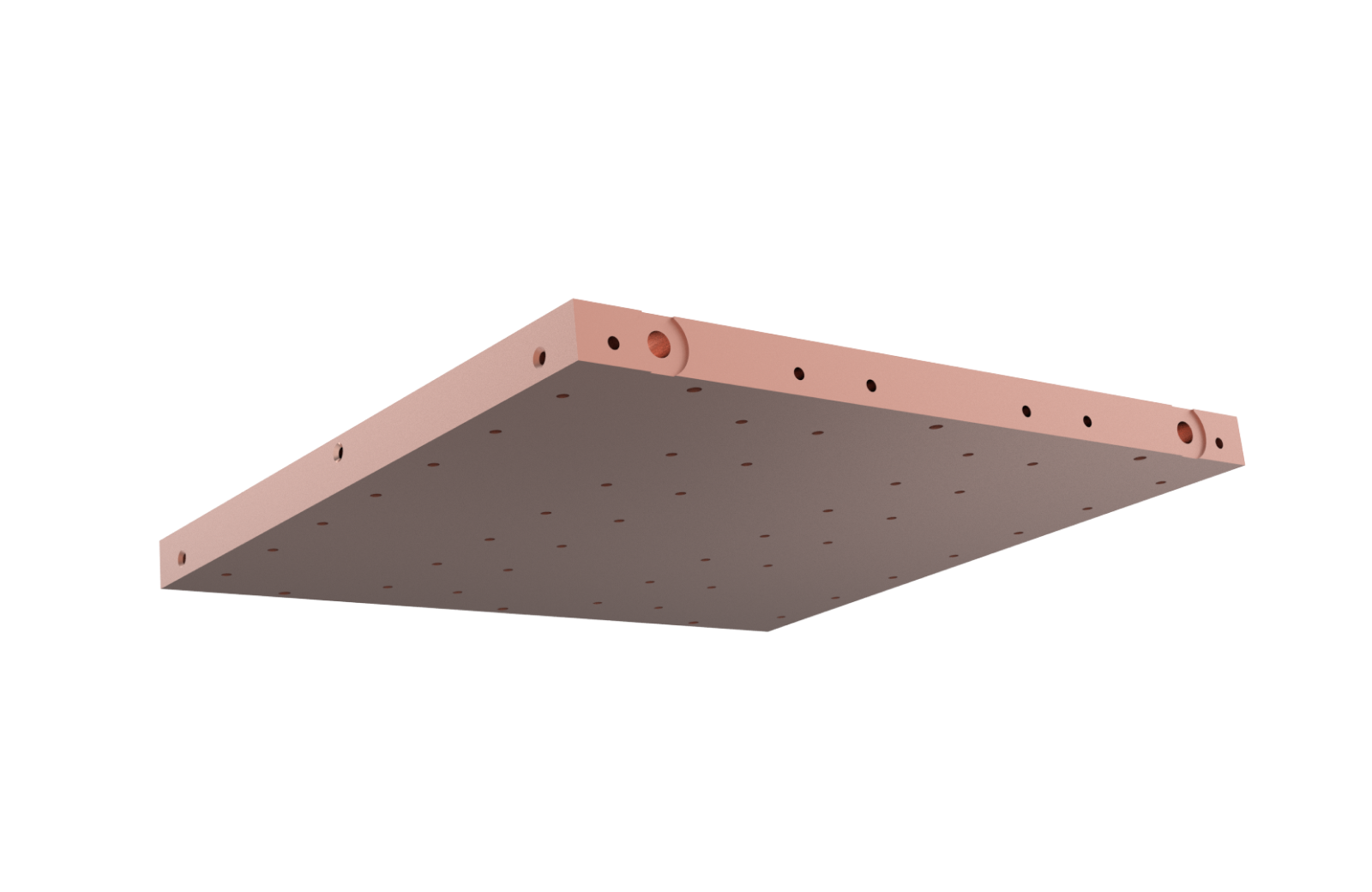

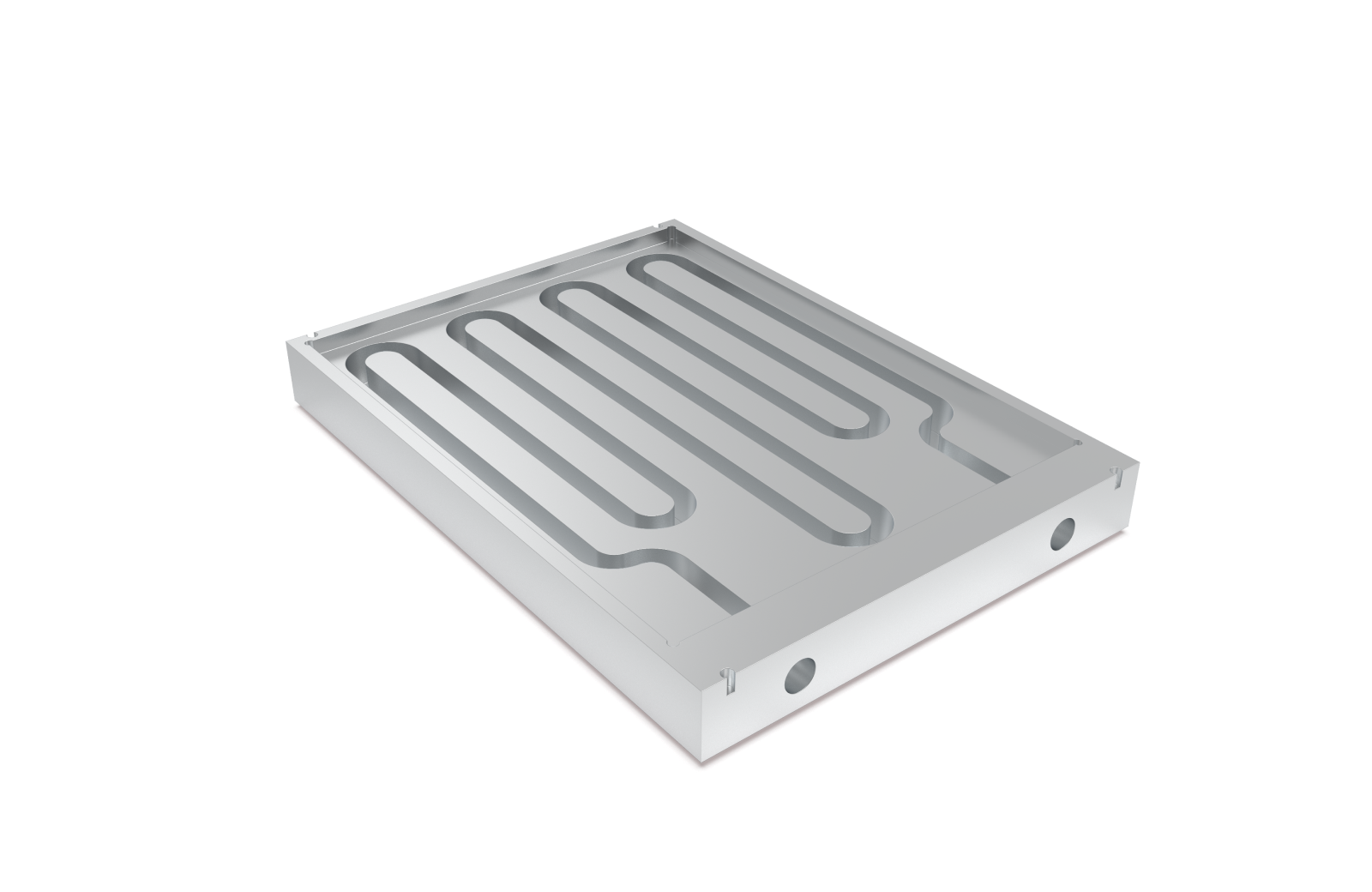

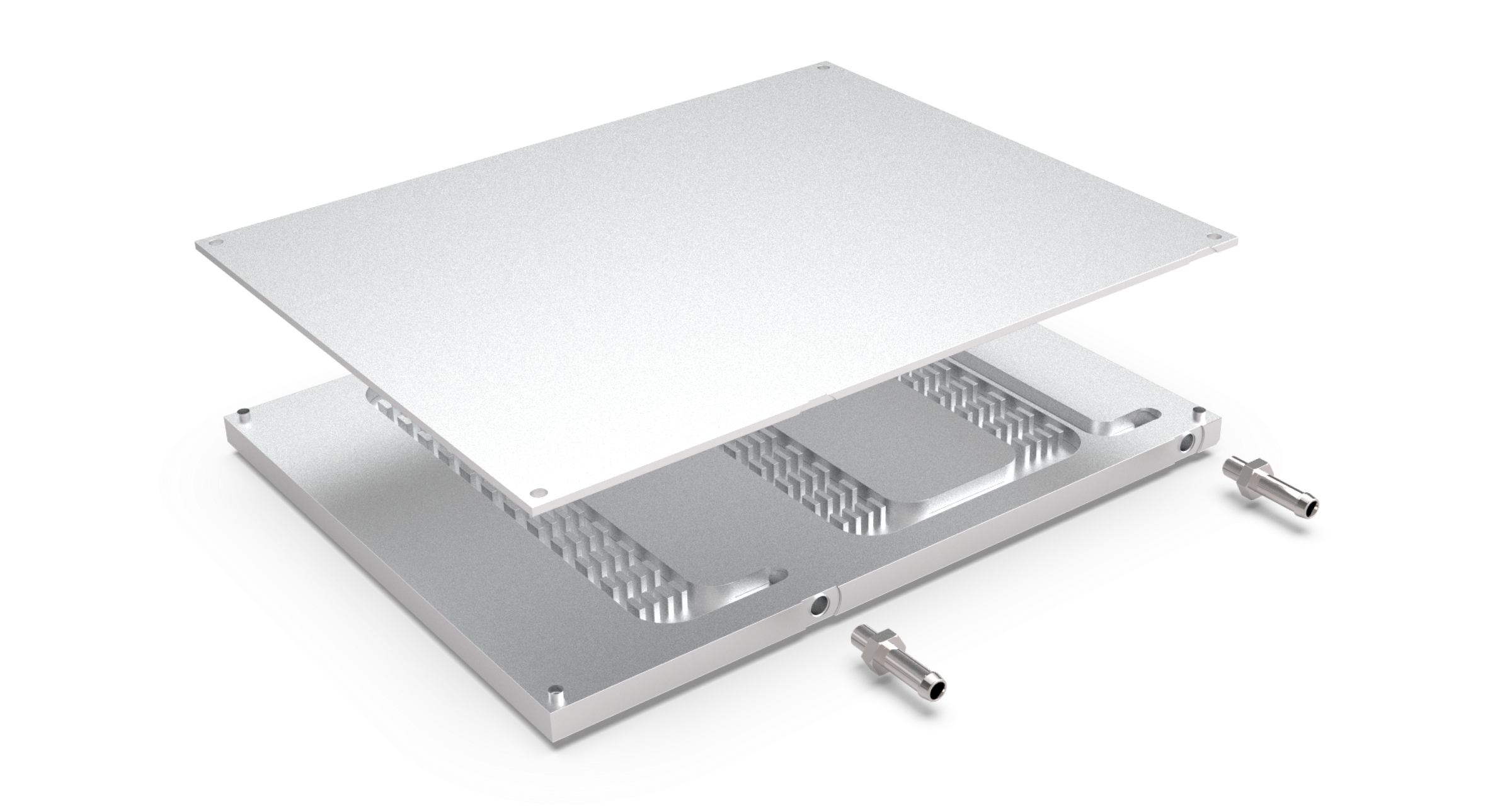

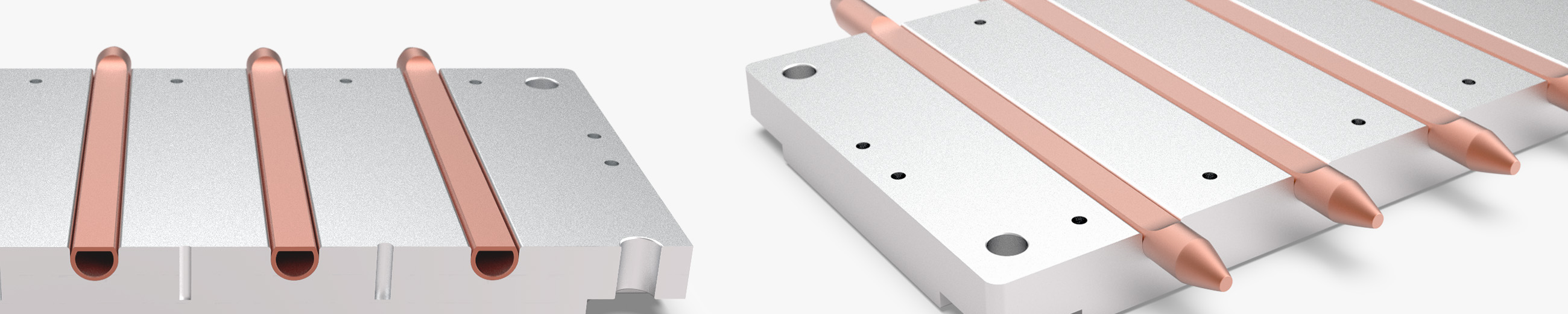

Milled or inserted channel and pin structures increase cooling performance and ensure stable temperatures in high-performance applications.

Learn more in a conversationIndividually designed cooling structures (milled or inserted)

Channels or pin structures for maximum thermal performance

Selection adapted to the application

Processes: friction stir welding, laser welding, vacuum brazing, or bonding

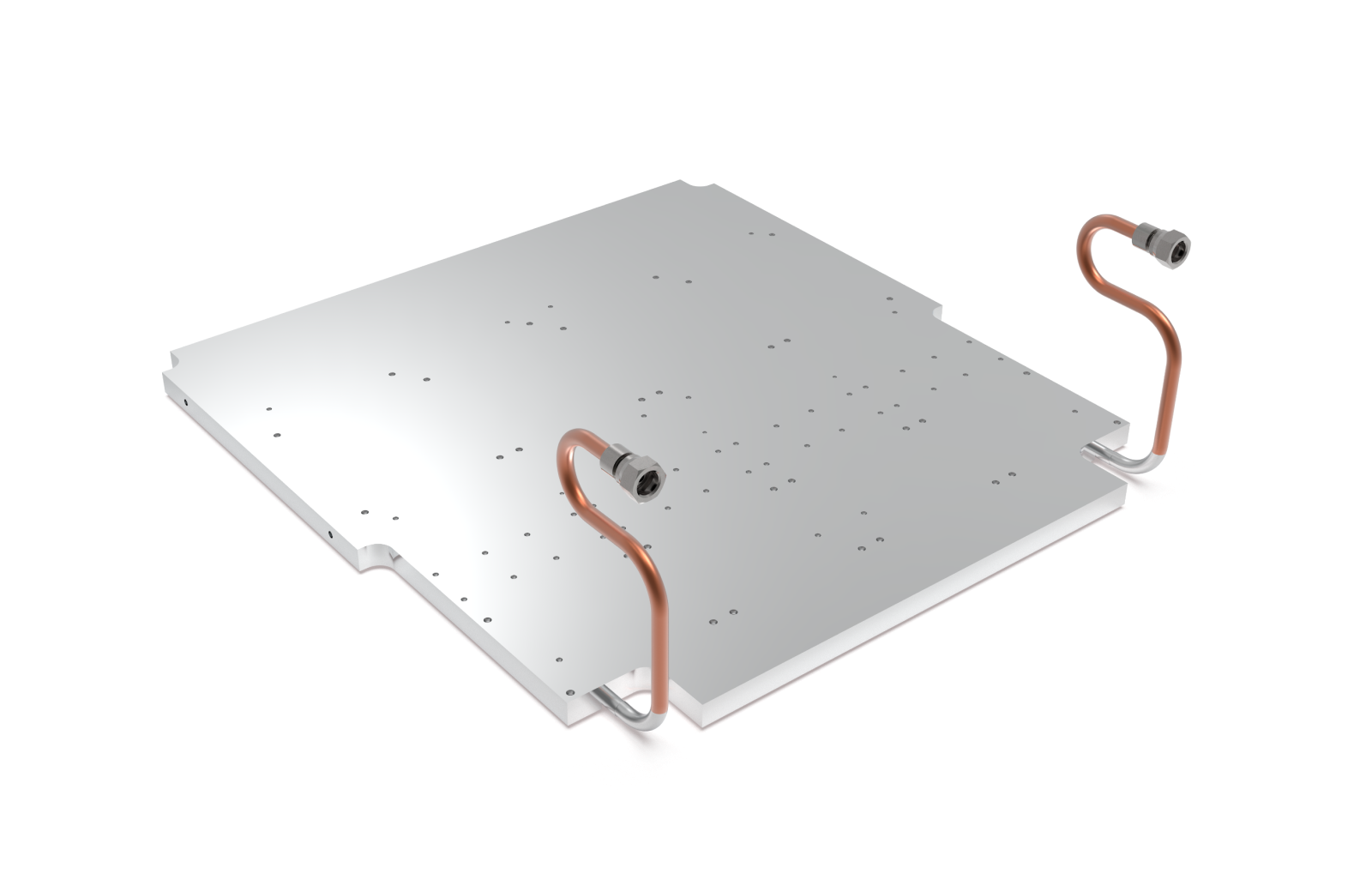

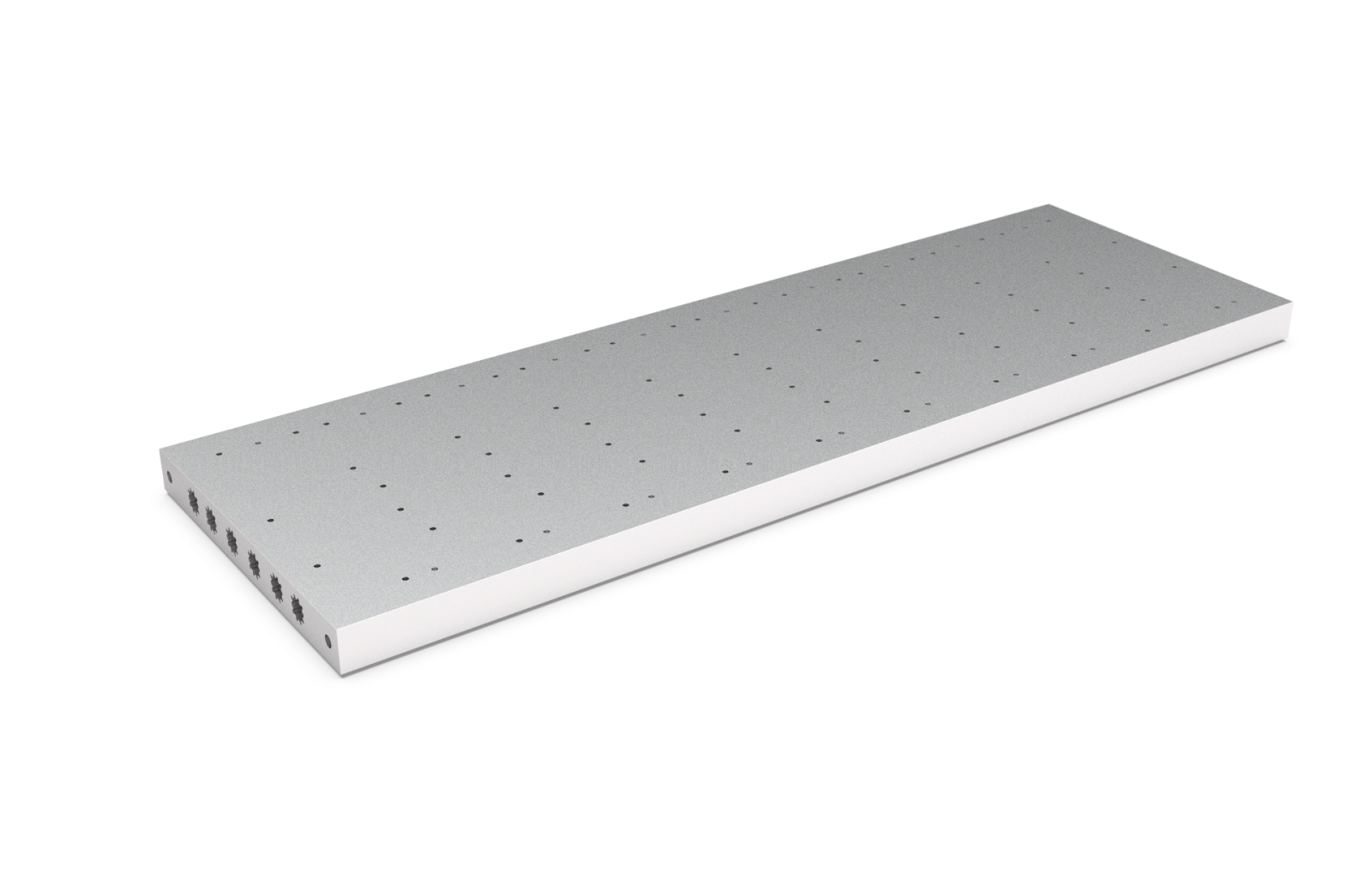

Uniform component cooling from both sides

No need for tubes on both sides

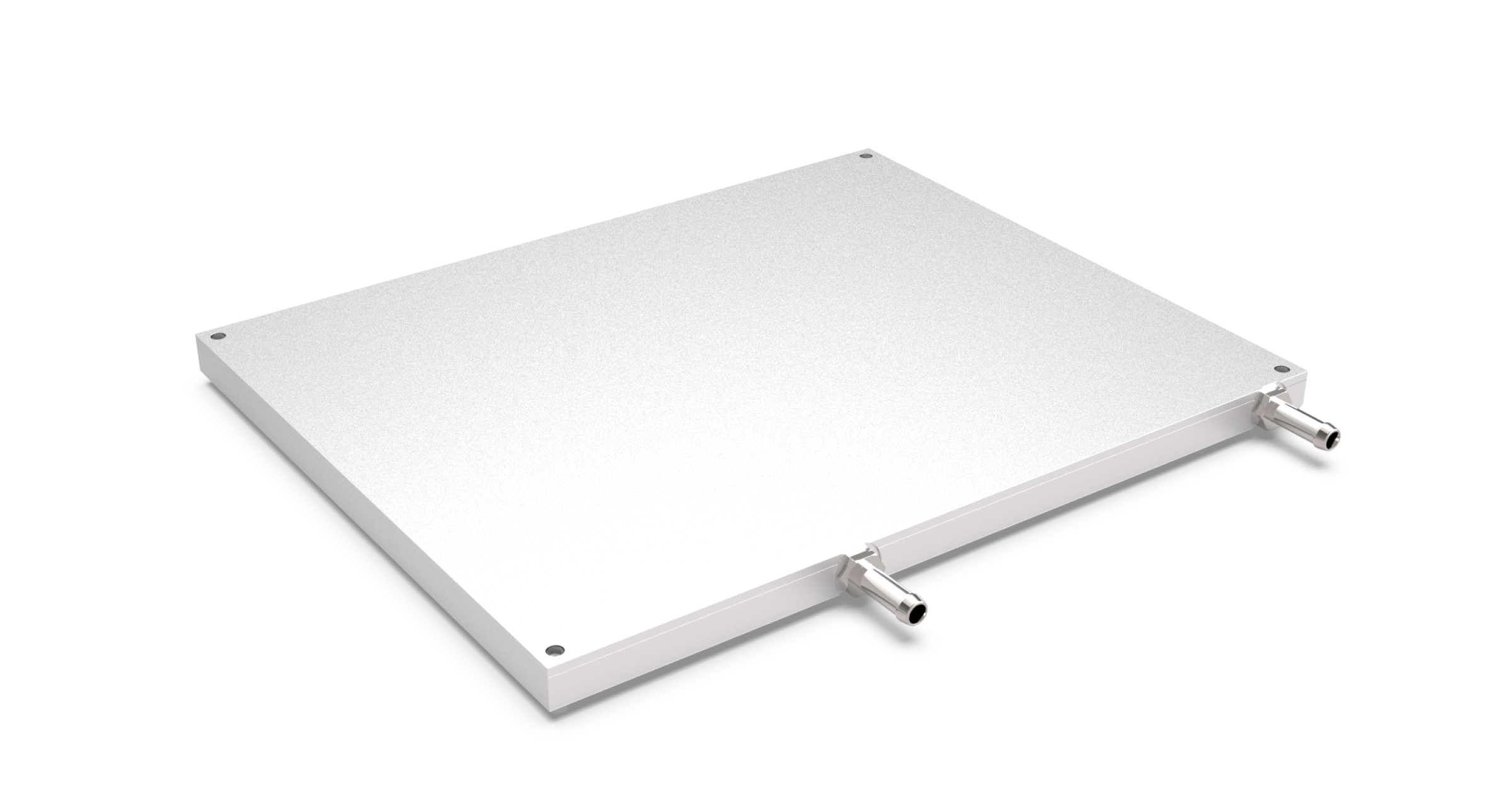

Liquid coolers with milled or inserted structures provide maximum flexibility and thermal performance.

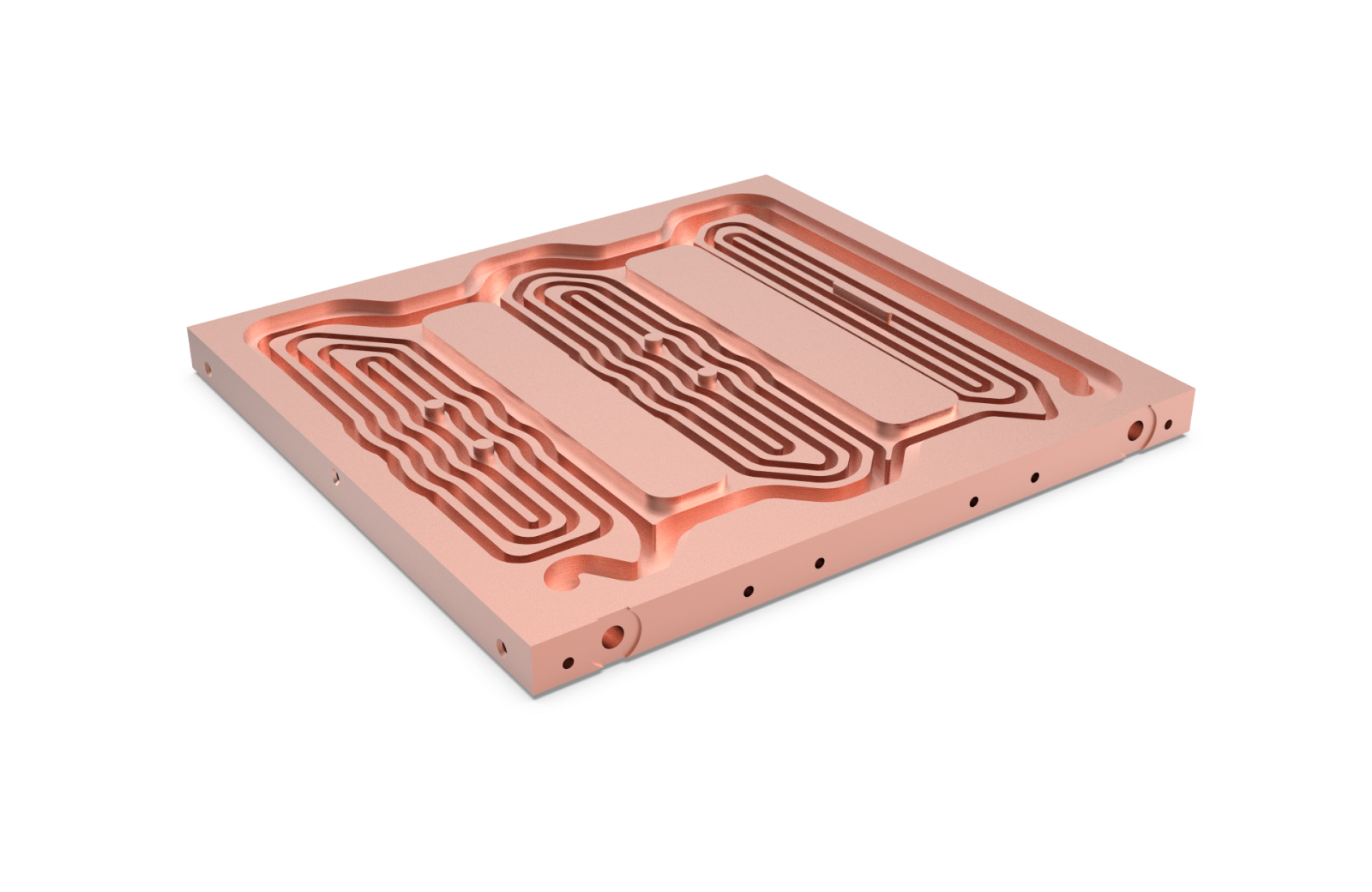

Complex geometries such as channels, pins, honeycombs, or fins can be realized. The suitable joining method is selected individually – from friction stir or laser welding to vacuum brazing or bonding. The combination of internal structure and joining method ensures efficient heat dissipation, stable temperatures, and high cost efficiency.

Learn more in a conversation

Custom channel and pin structures for optimal cooling performance

Flexible manufacturing process: welding, brazing, bonding, or additive methods

Implementation of complex geometries for efficient heat dissipation

High thermal stability and uniform component temperatures

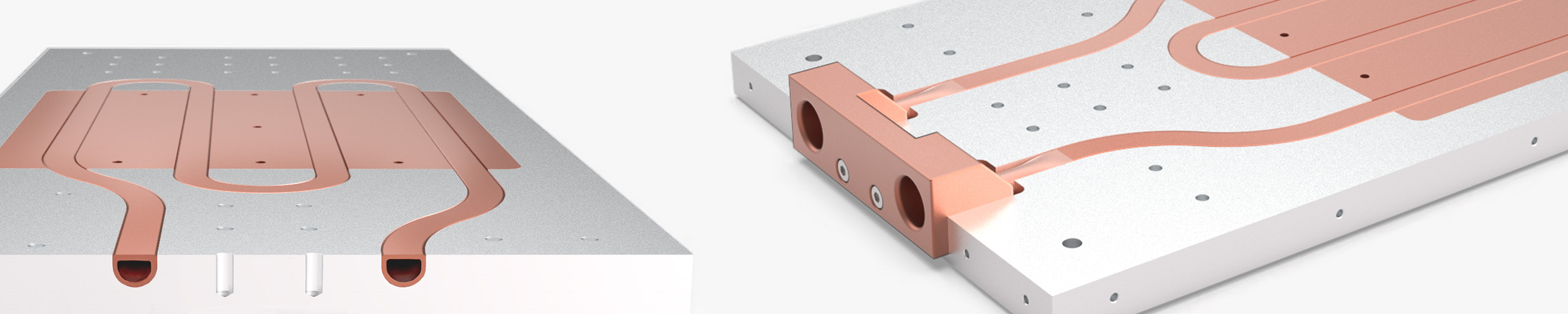

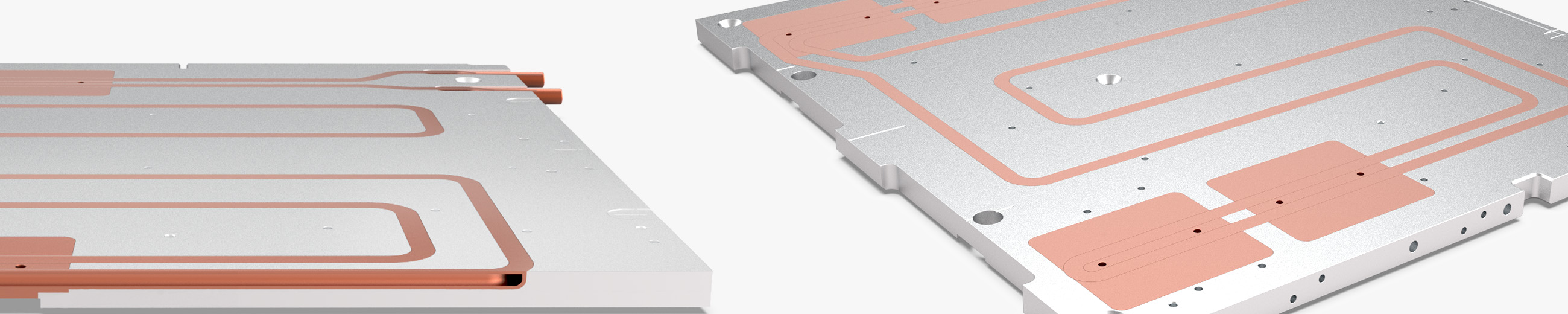

Copper or stainless-steel inserts transfer heat directly to the cooling medium, increasing the efficiency of your liquid cooling. Various alloys and surface treatments are available to prevent corrosion and extend lifespan.

Fluid-carrying inserts can be easily combined with milled or inserted channel and pin structures, ensuring even heat distribution across the entire cooling plate.

Copper inserts provide stable heat distribution, specifically reduce hotspots, and improve consistent temperature control across the cooler. Especially in high-performance or space-limited applications, they stabilize the operating temperatures of sensitive components and extend the lifetime of electronic modules.

Embedded heat pipes use phase-change technology, where liquid evaporates and condenses at cooler points. This enables extremely efficient heat transfer and minimizes hotspots. The technology is ideal for compact, high-performance applications where even temperature distribution is critical, significantly enhancing the thermal performance of structured and pin-type coolers.

COOLTEC’s digital thermal simulation enables fast, precise, and resource-efficient development of your cooling solution.

Whether analyzing existing designs or developing new ones, we optimize performance, material use, and installation space for maximum cooling efficiency.

Whether high-performance electronics or compact space: we develop cooling systems that combine performance and reliability. Fast, precise, and customized.

Structureflow coolers are ideal for applications with complex thermal requirements, high power density, or irregular component geometries. They provide uniform cooling and maximum efficiency.

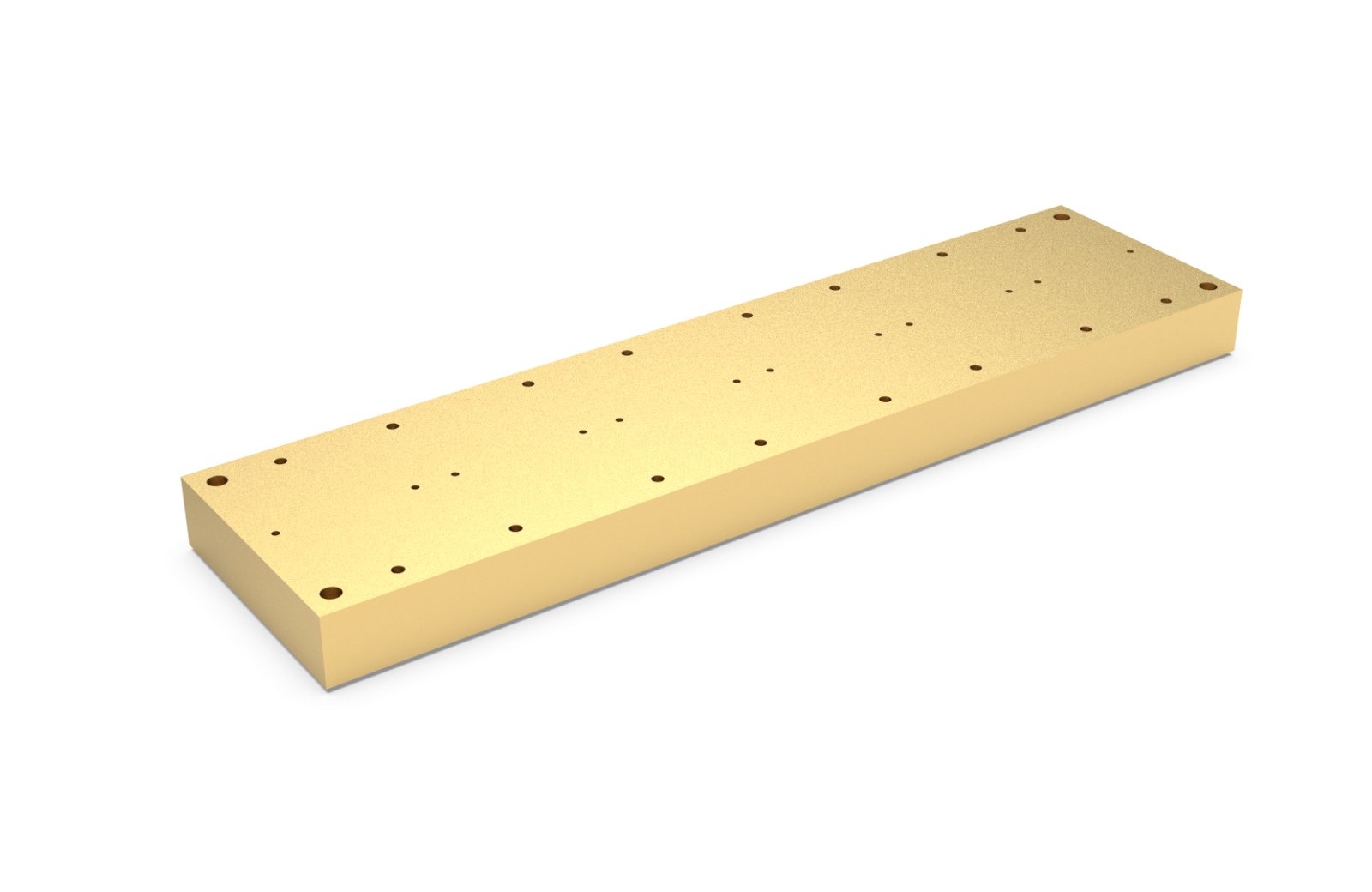

Standard materials include copper, aluminum, or stainless steel. Special alloys can be used depending on requirements for thermal conductivity, weight, and corrosion resistance.

The structures are milled or inserted to enhance heat dissipation. They allow targeted fluid flow and significantly improve thermal performance.