Forget the Rth value when choosing your cooling solution.

When selecting a heat sink for your system, there are several factors to consider. If you search for “heat sink selection,” you will likely encounter the following or a similar statement:

“The thermal resistance is an important metric when choosing a heat sink.”

We disagree! In this article, we will explain why we hold a different view and why the Rth value is not very informative. This applies to both air-cooled and liquid-cooled heat sinks. Therefore, we will refer generally to heat sinks below.

No Standard for Determining the Thermal Resistance of Heat Sinks

No Standard for Determining the Thermal Resistance of Heat Sinks

A major problem with the stated values for the thermal resistance of electronic heat sinks is that there is no standard for determining them (neither for calculation nor measurement). As a result, every manufacturer can determine the thermal resistance of their heat sinks differently, making comparisons between heat sinks difficult or even impossible. Especially when calculating the thermal resistance of a heat sink, one can easily optimize this value by cleverly choosing reference parameters, leading to values that the heat sink can never actually achieve in reality.

Complex Problems Cannot Be Reduced to a Single Metric

A simple example can illustrate how the Rth value can be manipulated by carefully selecting reference values. This example will focus on an air heat sink.

Example: Air Heat Sink

Assume a simple aluminum profile heat sink operating with natural convection. A heat source of 100 W is placed at the base of the heat sink, with an ambient temperature of 20°C. This configuration forms the basis for comparison.

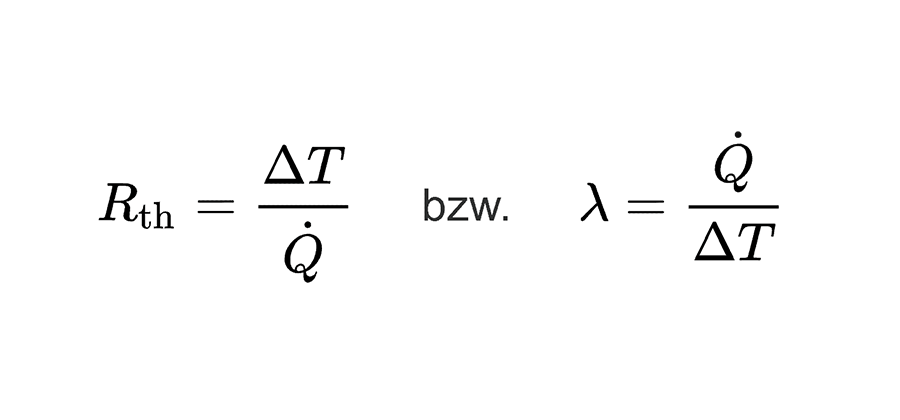

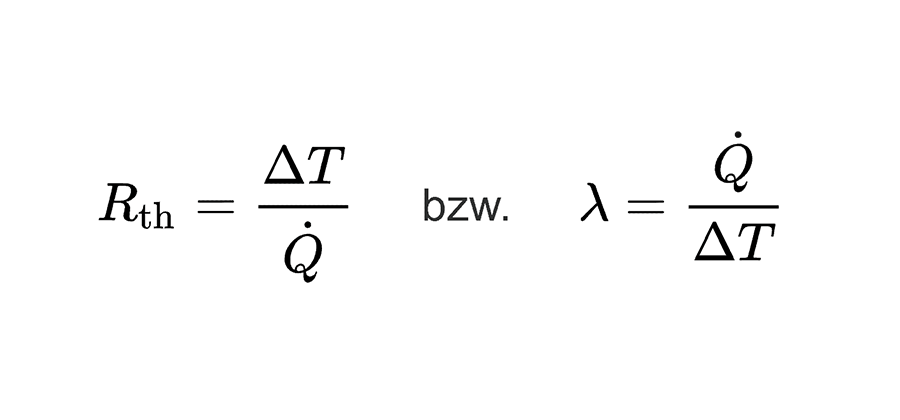

The thermal resistance is calculated using the formula:

Rth = ΔT/Q = (T_heat_sink - T_ambient) / P_loss

Even when examining the formula, you can see that the cooling temperature directly affects the Rth value. But which temperature should be used? Naturally, as a heat sink manufacturer, I would choose the lowest possible temperature to make the thermal resistance appear as low as possible.

There are numerous ways to influence the heat sink temperature. Some examples for an aluminum profile heat sink:

• Location of temperature measurement

• Use of thermal paste (reducing contact resistance)

• Distributing the same heat loss over a larger surface area

• Installation orientation

• Surface finish (heat radiation)

For a liquid cooler, the calculation is very similar. Here, however, the heat flow is dissipated by the flowing liquid. The determination of the Rth value for a liquid cooler is also not standardized, so it can be manipulated similarly by cleverly selecting the reference parameters.

Examples for influencing the temperature of a liquid cooler:

• Location of temperature measurement

• Use of thermal paste (reducing contact resistance)

• Distributing the same heat loss over a larger surface area

This example has shown that even for identical heat sinks, different thermal resistance values can be determined simply by carefully choosing the reference parameters. Therefore, comparing different heat sinks, especially between manufacturers, is very difficult or nearly impossible. The provided Rth values always offer only a rough estimate, which is only accurate for a specific configuration (installation orientation, heat loss distribution, etc.).

The Boundary Conditions Are (Almost) Always Different in Practice

In almost every project, the ambient and boundary conditions vary, making comparisons difficult. What does this mean for you as a user or developer? How can you estimate the performance of your thermal management system?

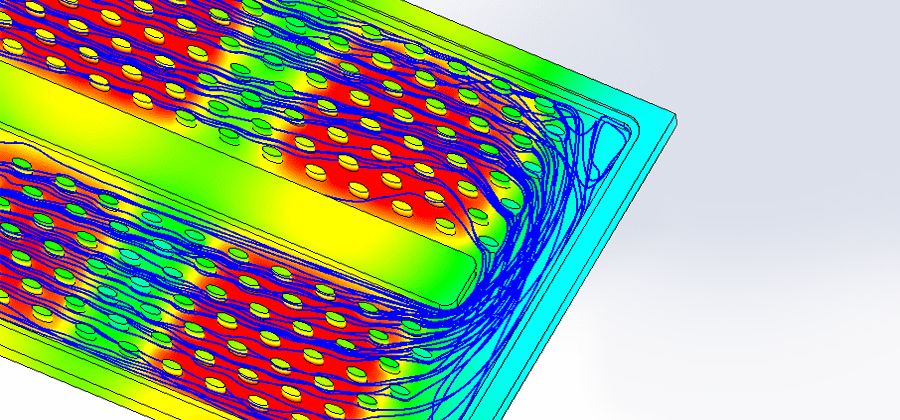

Using thermal simulations, all relevant thermal influences can be modeled and simulated. Thanks to our extensive experience at Cool Tec Electronic, we can quickly assess feasibility and offer you reliable comparisons of different alternatives. We also keep the cost-benefit factor in mind. Whether you need air or water cooling, we can simulate both cooling methods accurately.