Developing Heat Sinks Using Thermal Simulations

Published: 15.08.2024

The development and optimization of cooling solutions can be carried out through two different methods:

Author: Benedikt Lausberg

Artificial Intelligence (AI) is revolutionizing the field of thermal technology, providing new tools and techniques to improve the design, analysis, and control of thermal systems.

One of the most significant areas where AI has a profound impact is in optimizing thermal systems. Traditional optimization methods, such as gradient descent, can be very time-consuming and computationally intensive when applied to complex thermal systems. AI-based optimization algorithms, such as genetic algorithms and neural networks, can deliver faster and more accurate solutions. These algorithms can also handle a larger number of design variables and constraints, enabling more comprehensive system optimization.

Another area where AI makes a difference is in the prediction and control of thermal systems. Conventional control methods, such as PID control (Proportional-Integral-Derivative control), rely on mathematical models that can be difficult to develop and maintain for complex thermal systems. AI-based control methods, such as fuzzy logic and machine learning, allow for more precise and robust system control, even in the presence of uncertainties and nonlinearities.

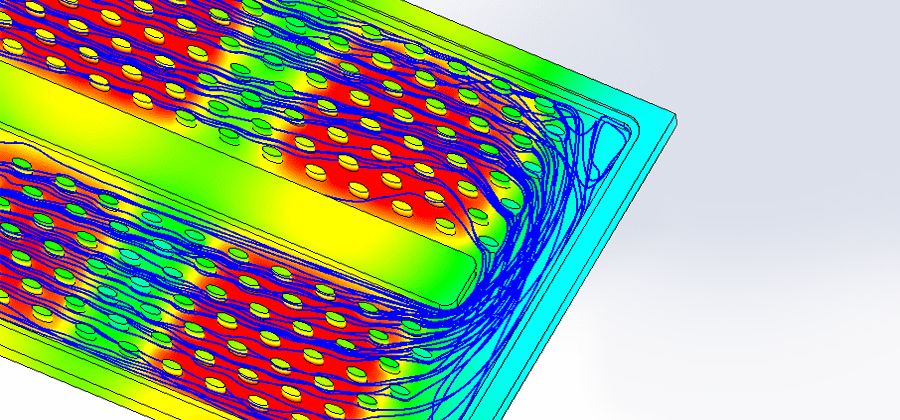

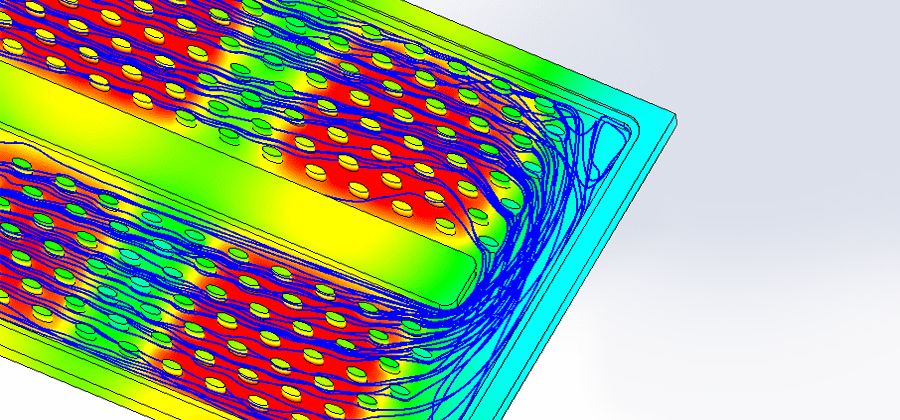

Artificial intelligence is also used to improve the accuracy of thermal simulations. Traditional simulation methods, such as finite element analysis (FEA) and computational fluid dynamics (CFD), rely on mathematical models that can be computationally demanding and may not fully capture the complex physics of real-world systems. AI-based simulation techniques, such as deep learning, can provide more accurate predictions of a system’s thermal performance, even for complex geometries and boundary conditions.

In summary, AI offers powerful tools for enhancing the design, analysis, and control of thermal systems. These tools help engineers optimize system performance, predict and control behavior, and improve the accuracy of thermal simulations.

© 2026 - Cool Tec Electronic GmbH

Published: 15.08.2024

The development and optimization of cooling solutions can be carried out through two different methods:

Published: 15.08.2024

When selecting a heat sink for your system, there are several factors to consider. If you search for “heat sink selection,” you will likely encounter...

Published: 15.08.2024

All processes and technical applications must be made emission-free as quickly as possible. For this purpose, renewable energies such as solar power...