The development and optimization of cooling solutions can be carried out through two different methods: either relying on empirical values and creating multiple prototype variants that are then tested, or replacing lengthy trial setups and prototypes with intelligent development using thermal simulations and underlying artificial intelligence.

At Cool Tec Electronic, we now exclusively use the development process based on thermal simulations, offering the following advantages:

Speed:

Multiple variants based on existing or entirely new models can be simulated, compared, and optimized within a short period to find the ideal cooling solution for the given requirements. The result is guaranteed to work and be technologically and economically feasible without the need for multiple prototype cycles.

Cost-effectiveness:

Accelerated development times, reduced material and manufacturing effort for prototypes, and a perfectly optimized cooling solution compared to standard solutions.

Sustainability:

The fully virtual development process minimizes material and energy usage. It also enables direct comparisons of sustainable manufacturing processes. For example, alternative sustainable methods can be evaluated and implemented only after achieving positive simulation results.

The Thermal Simulation Process at Cool Tec Electronic:

We follow a structured development process with the highest expectations for quality and efficiency.

Each inquiry about a new cooling solution or the optimization/redesign of an existing heat sink begins with a non-binding initial consultation with the responsible Key Account Manager. This meeting helps understand requirements and expectations and familiarize with the customer’s organization. If a thermal simulation makes sense for the customer, the necessary formalities (e.g., NDA) and existing models (e.g., 3D models, sketches) are exchanged, along with environmental, performance, and thermal parameters.

With this information, one of our thermal engineers prepares for the next free-of-charge expert consultation. During this meeting, preliminary considerations based on the model are presented, additional information is gathered, and a transparent offer for the desired cooling solution is created.

After offer acceptance, the development process unfolds as follows:

Step 1 – Initial Phase:

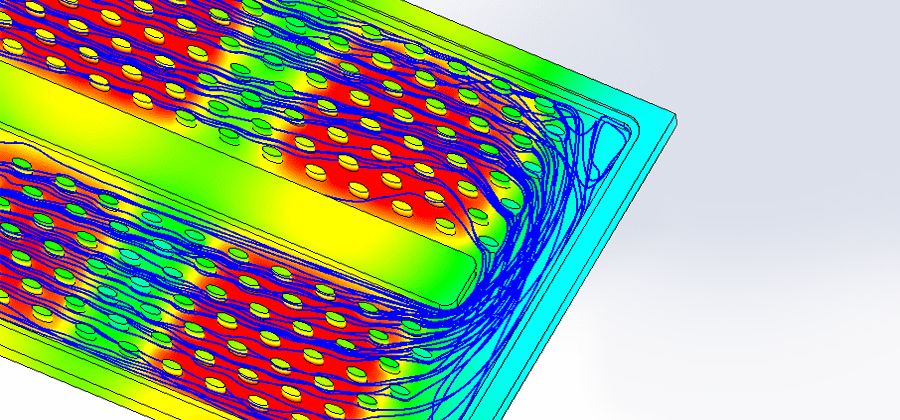

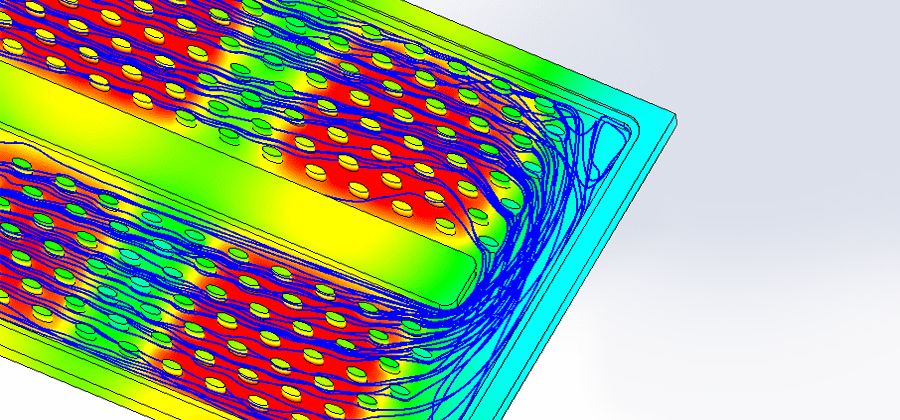

For new projects, our technology draws on existing comparison projects and products, optimized by our experts to meet the current requirements. If a system is already in use, we simulate it to determine the current thermal state, which helps identify thermal hotspots.

Step 2 – Development and Optimization Phase:

We optimize the design based on the initial draft and preferred technologies. If no specific expectations are provided by the customer, we optimize according to three criteria: thermal performance, economic manufacturability, and sustainability in materials and resources.

Step 3 – Results Phase:

In this phase, we evaluate the optimization results, select the most efficient variants, and present them to the customer.

Typically, this phase is followed by the production of prototypes for functional test cycles since thermal performance is already understood. If desired, we test the prototypes under lab conditions and compare them with the simulation results.