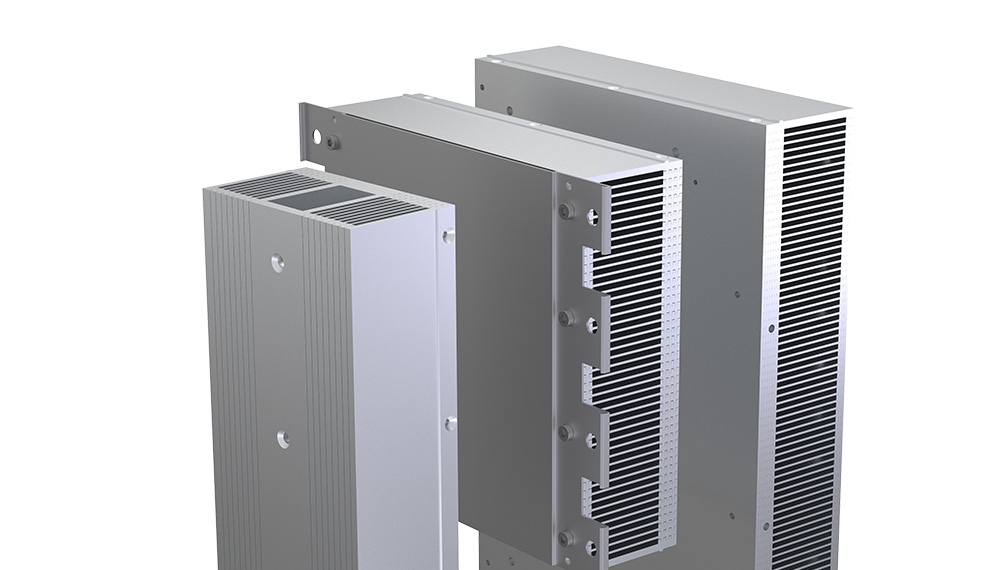

Side Pressed Fin Heat Sinks

Discover how you can cool efficiently in a compact, double-sided design – ideal for limited space.

Precision is crucial for the function and lifespan of air and liquid heat sinks. At COOLTEC, state-of-the-art inspection methods ensure that all components meet the required tolerances – from prototype to series production. This guarantees high quality, process reliability, and repeatable precision.

Learn more in a conversationSelf-inspection allows skilled workers to check the manufactured parts directly during production.

Early detection of deviations

Ensures high precision

Efficient, process-oriented quality control

Tactile measuring methods directly and precisely check component dimensions. Even the smallest deviations are reliably detected.

Highest accuracy

Supports strict quality standards

Ensures process reliability

Optical systems enable contactless inspection of geometries and surfaces using modern image processing.

High-precision, fast measurements

No impact on the workpiece

Optimal control of complex structures

Maintaining tolerances is essential to:

Ensure precisely fitting heat sinks and liquid coolers

Guarantee mechanical strength and thermal efficiency

Minimize complaints and rework

The combination of precise manufacturing and advanced measuring technology guarantees durable, reliable cooling solutions that meet the highest quality standards.

Continuous, process-oriented quality control

Early detection of deviations

Repeatable precision in small and large series

Combination of tactile and optical measurement for maximum reliability

Our precise measuring methods ensure your heat sinks and liquid coolers are manufactured exactly. Every deviation is detected early to guarantee the highest quality, safety, and performance.