Developing Heat Sinks Using Thermal Simulations

Published: 10.10.2022

The development and optimization of cooling solutions can be carried out through two different methods:

Author: Benedikt Lausberg

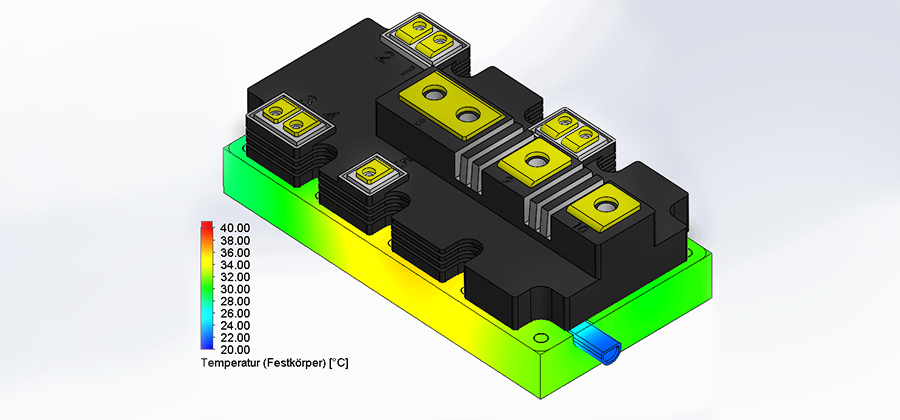

There are numerous ways to cool components based on their specific requirements. All methods share the goal of dissipating the heat generated from power loss into the surrounding air. However, the working principles of cooling solutions differ significantly. This article introduces the various working principles and product technologies available.

Air Coolers for Power Electronics

Direct air cooling using profile heat sinks for electronic components is the simplest and most cost-effective cooling method. The base material for profile heat sinks is typically produced through an extrusion process with high manufacturing volumes, resulting in excellent efficiency. Minimum press quantities vary between 500 kg and 2,000 kg depending on the extrusion profile, so the required quantity of heat sinks must be carefully considered. At Cool Tec Electronic alone, we have over 500 tools for custom heat sink profiles at our extrusion plants across Germany and Europe.

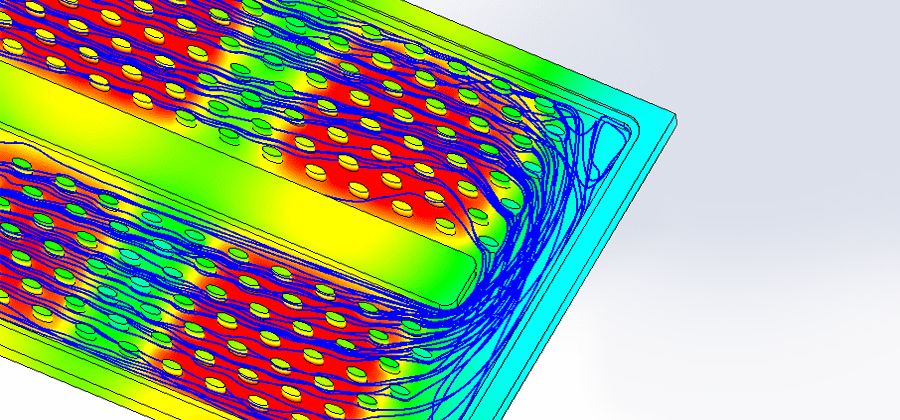

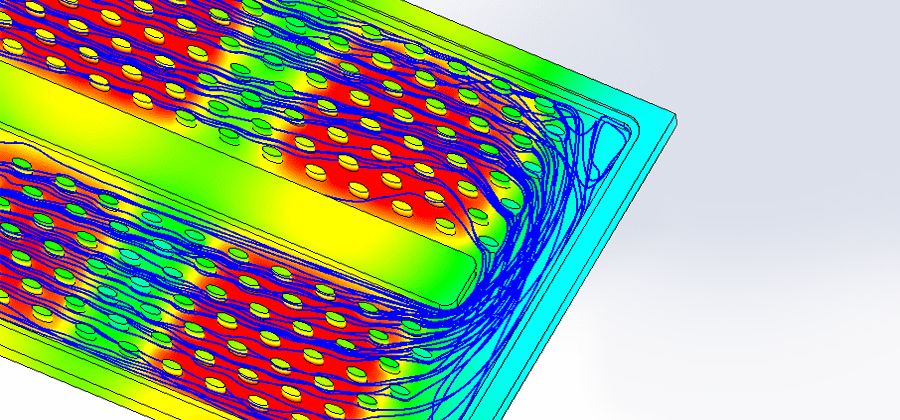

How Does an Air Cooler Work?

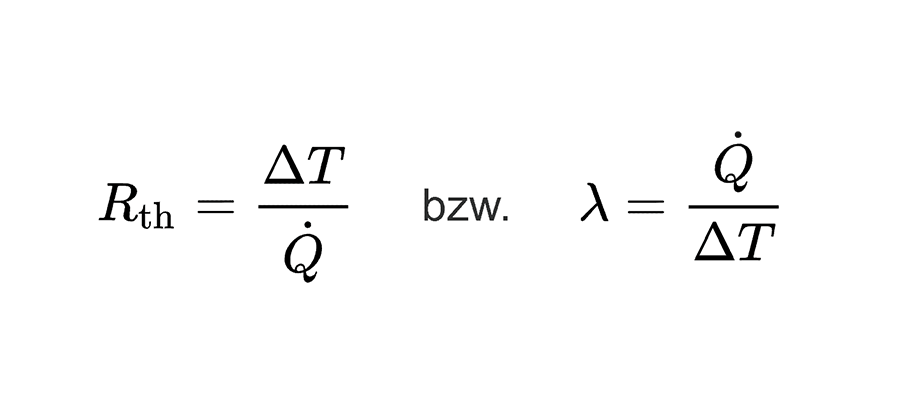

The principle of air cooling can be best explained using the formula for heat flux:

Cooling power = Heat transfer coefficient * Surface area * Temperature difference (Component and ambient air)

For air coolers, the cooling capacity depends on the heat-transferring surface area. Therefore, the goal when designing a profile heat sink is to maximize the surface area in contact with the air.

By incorporating specially designed cooling fins, the heat-transferring surface area between the heat sink and the air is significantly increased, maximizing the cooling capacity according to the formula above.

When Should I Use an Air Cooler?

Air coolers significantly increase the heat-transferring surface area, which also increases the physical space required. Therefore, sufficient space must be considered during the design phase. Since free airflow is essential, a tightly packed setup may not be effective. However, using fans can mitigate this issue to some extent. Nevertheless, if the power density (heat loss per volume) is too high, air coolers may reach their limitations quickly.

© 2026 - Cool Tec Electronic GmbH

Published: 10.10.2022

The development and optimization of cooling solutions can be carried out through two different methods:

Published: 10.10.2022

When selecting a heat sink for your system, there are several factors to consider. If you search for “heat sink selection,” you will likely encounter...

Published: 10.10.2022

In the world of heat dissipation and thermal management, thermal interface materials are crucial.