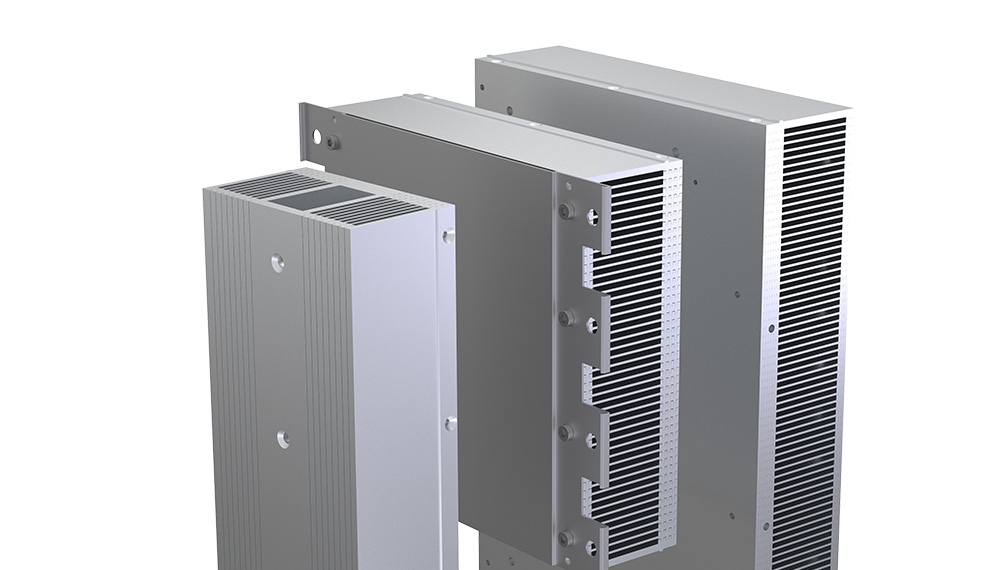

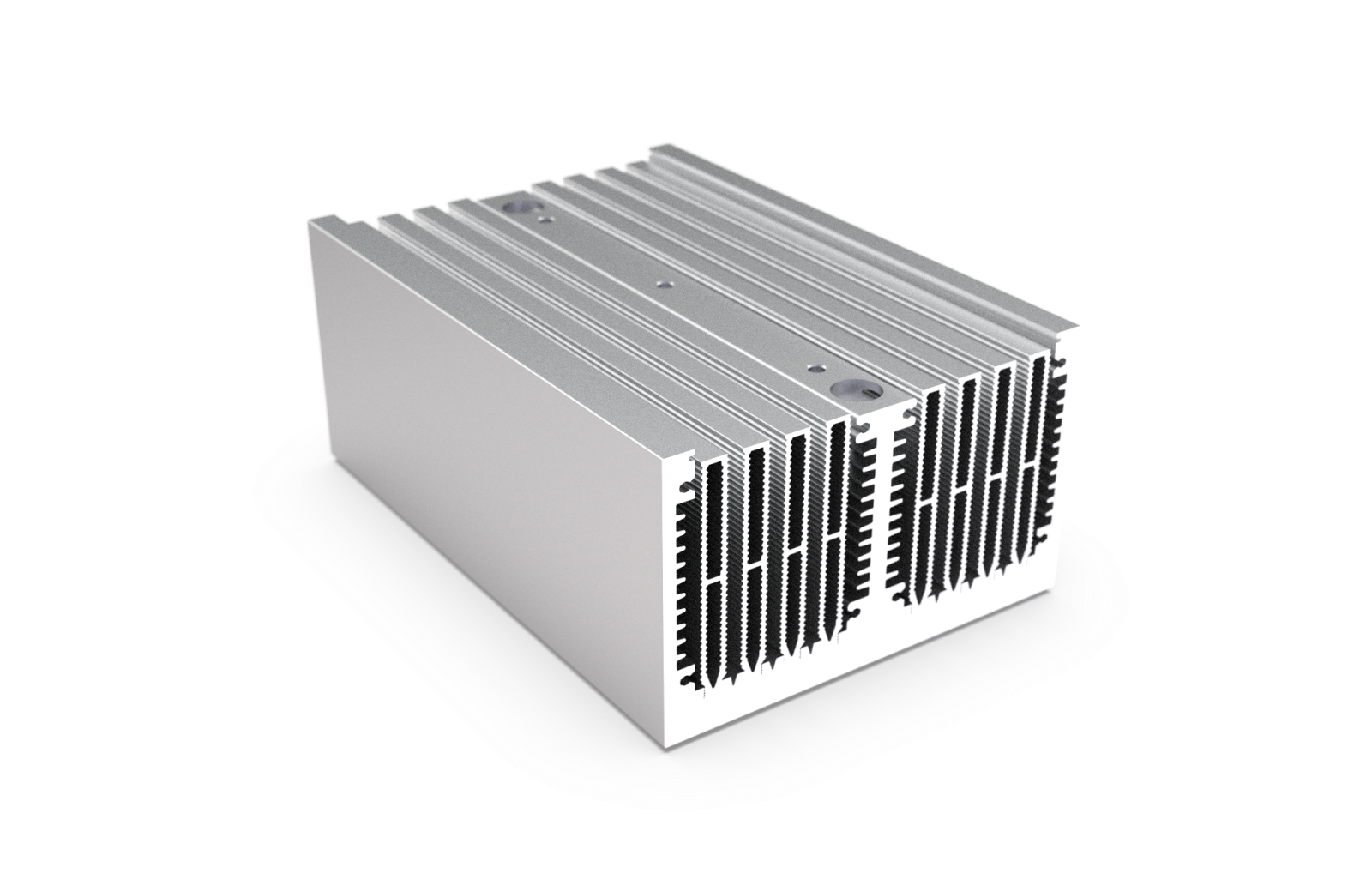

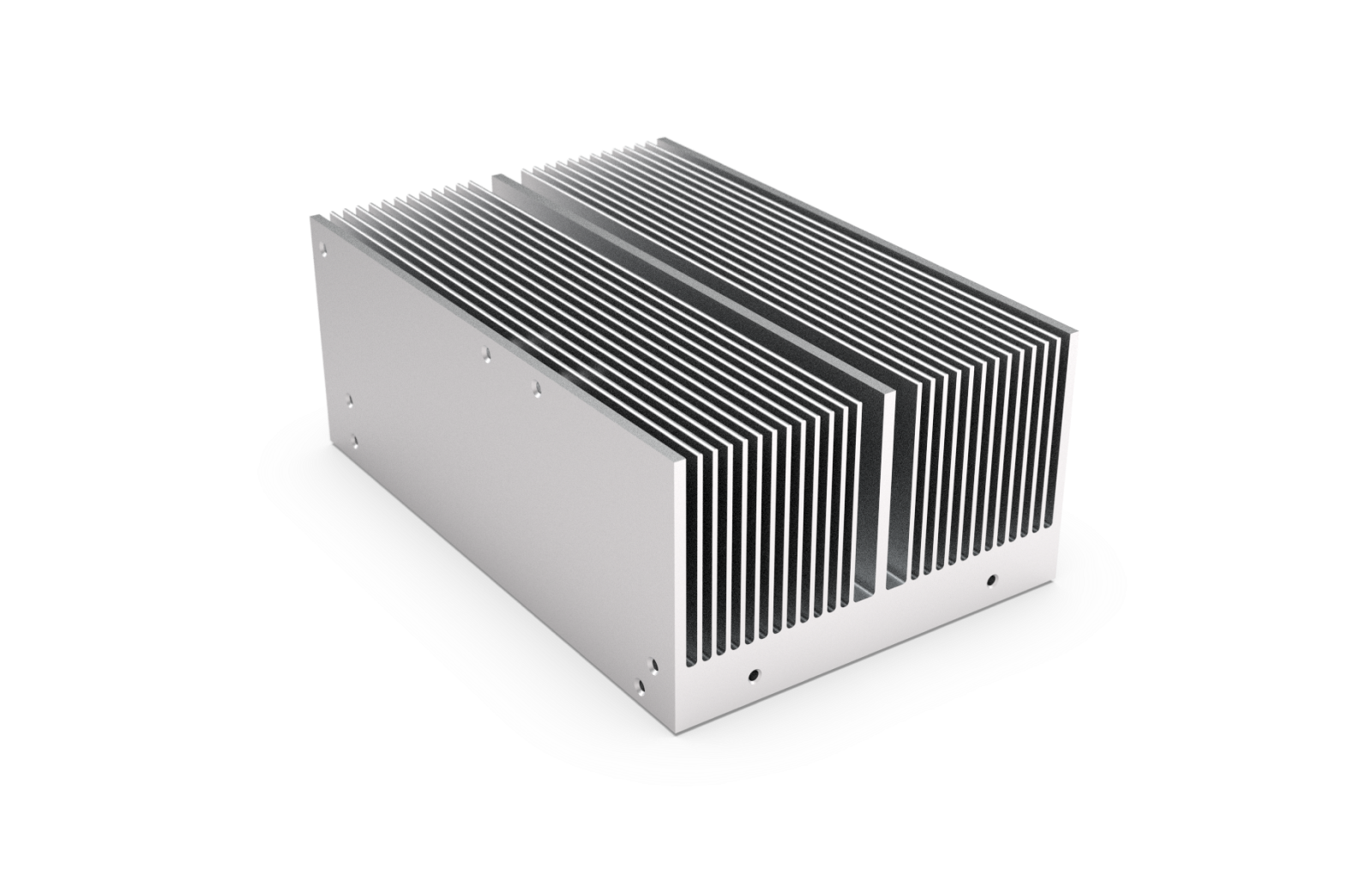

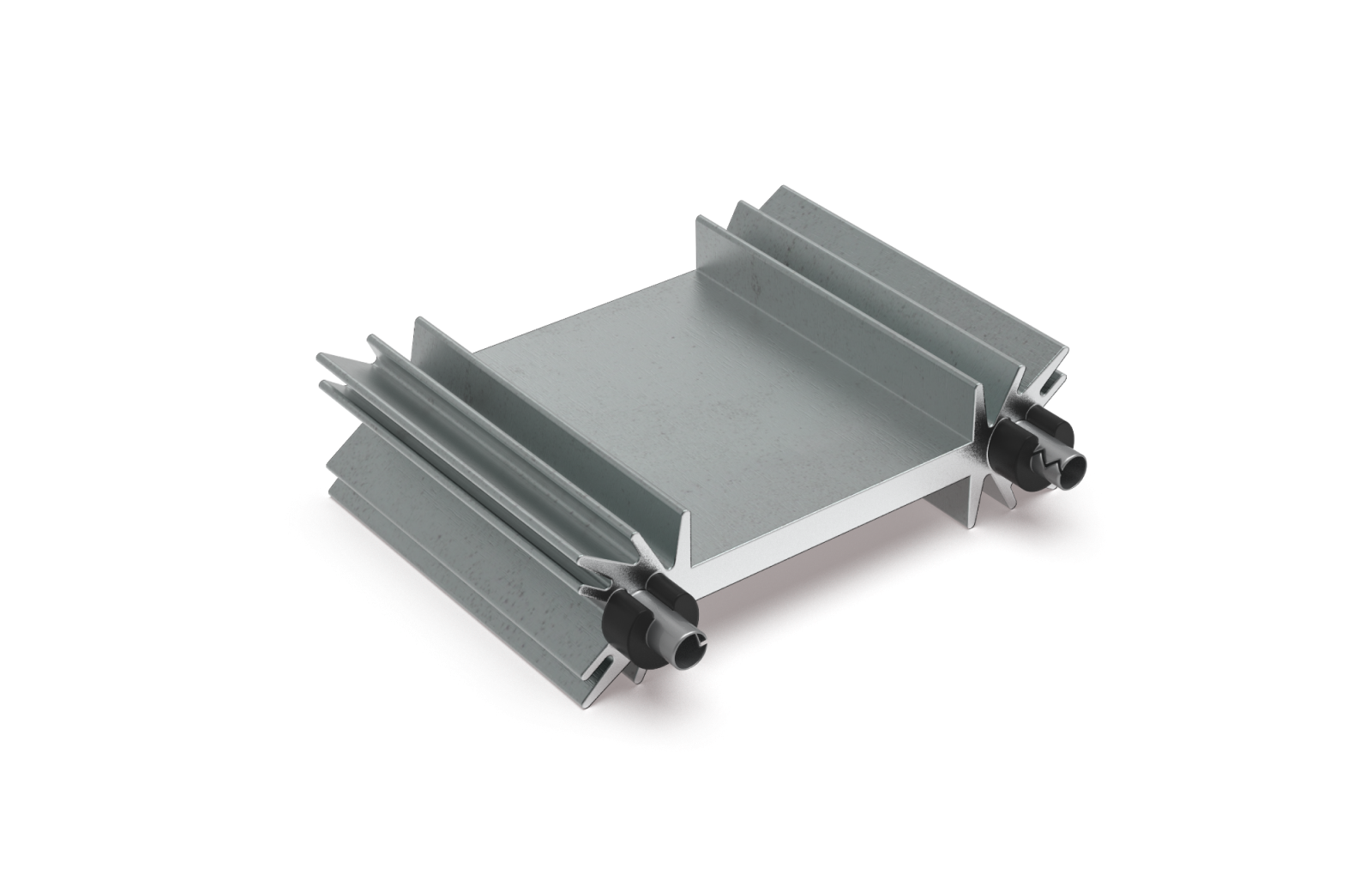

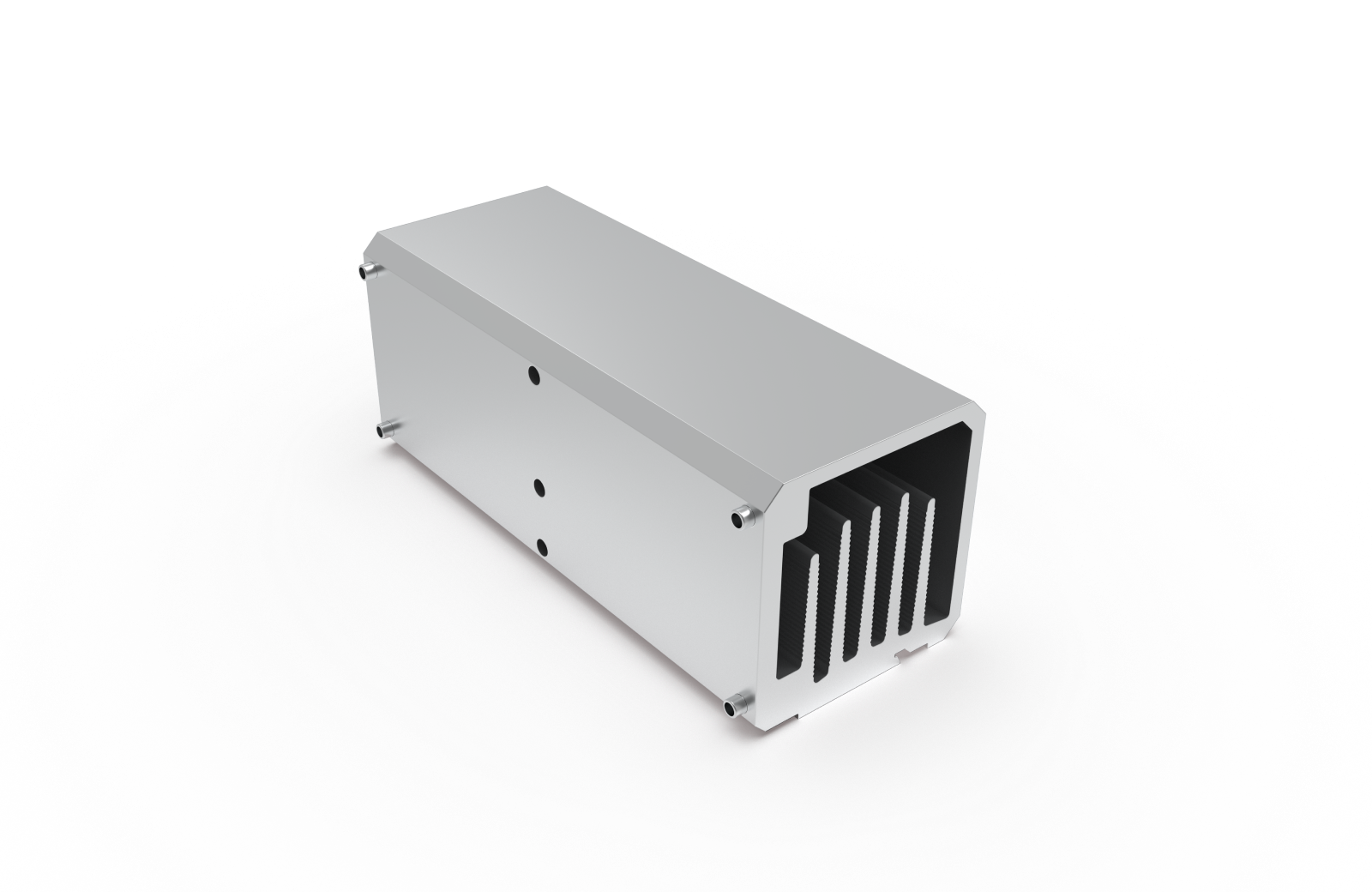

Side Pressed Fin Heat Sinks

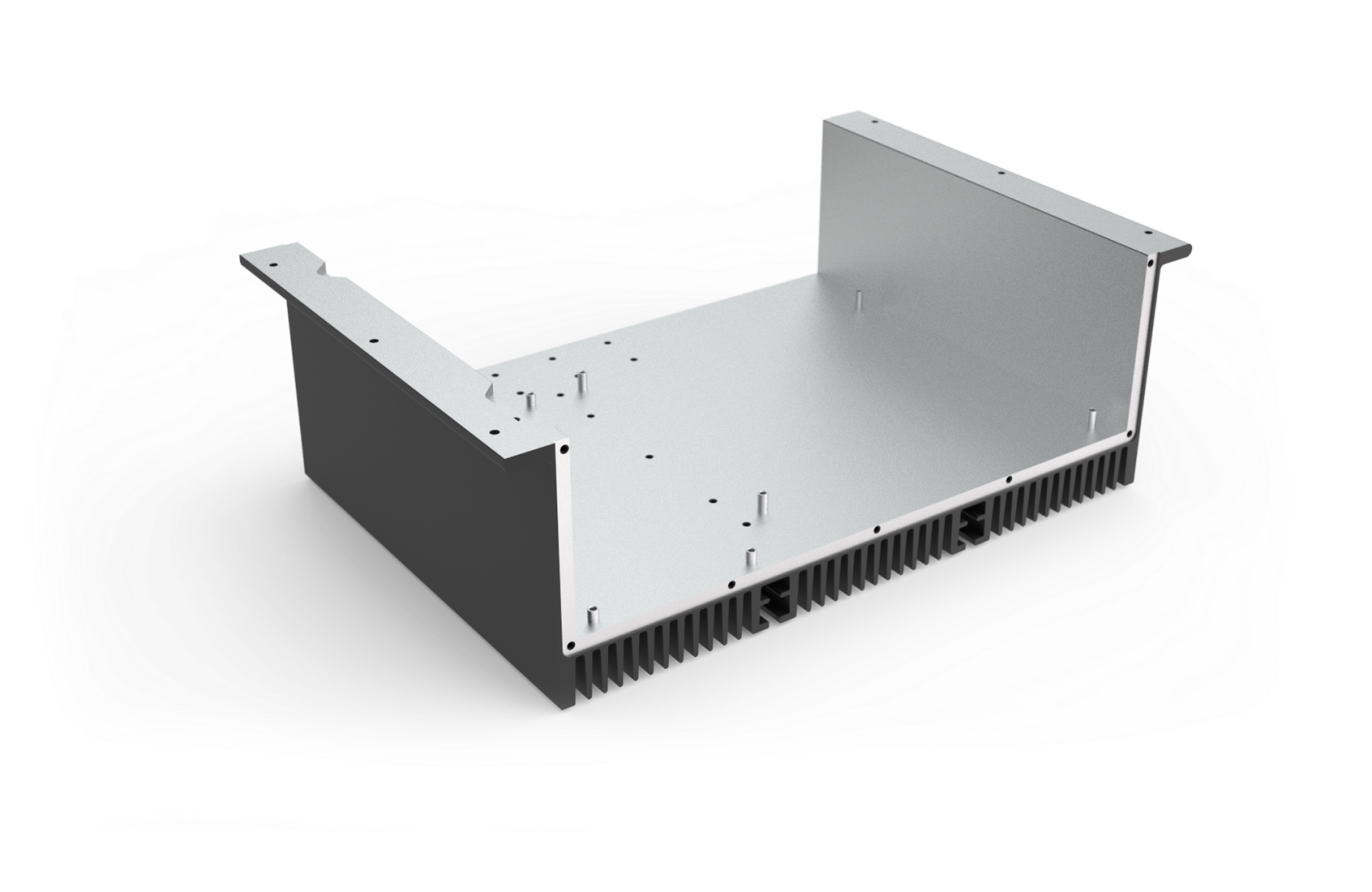

Discover how you can cool efficiently in a compact, double-sided design – ideal for limited space.

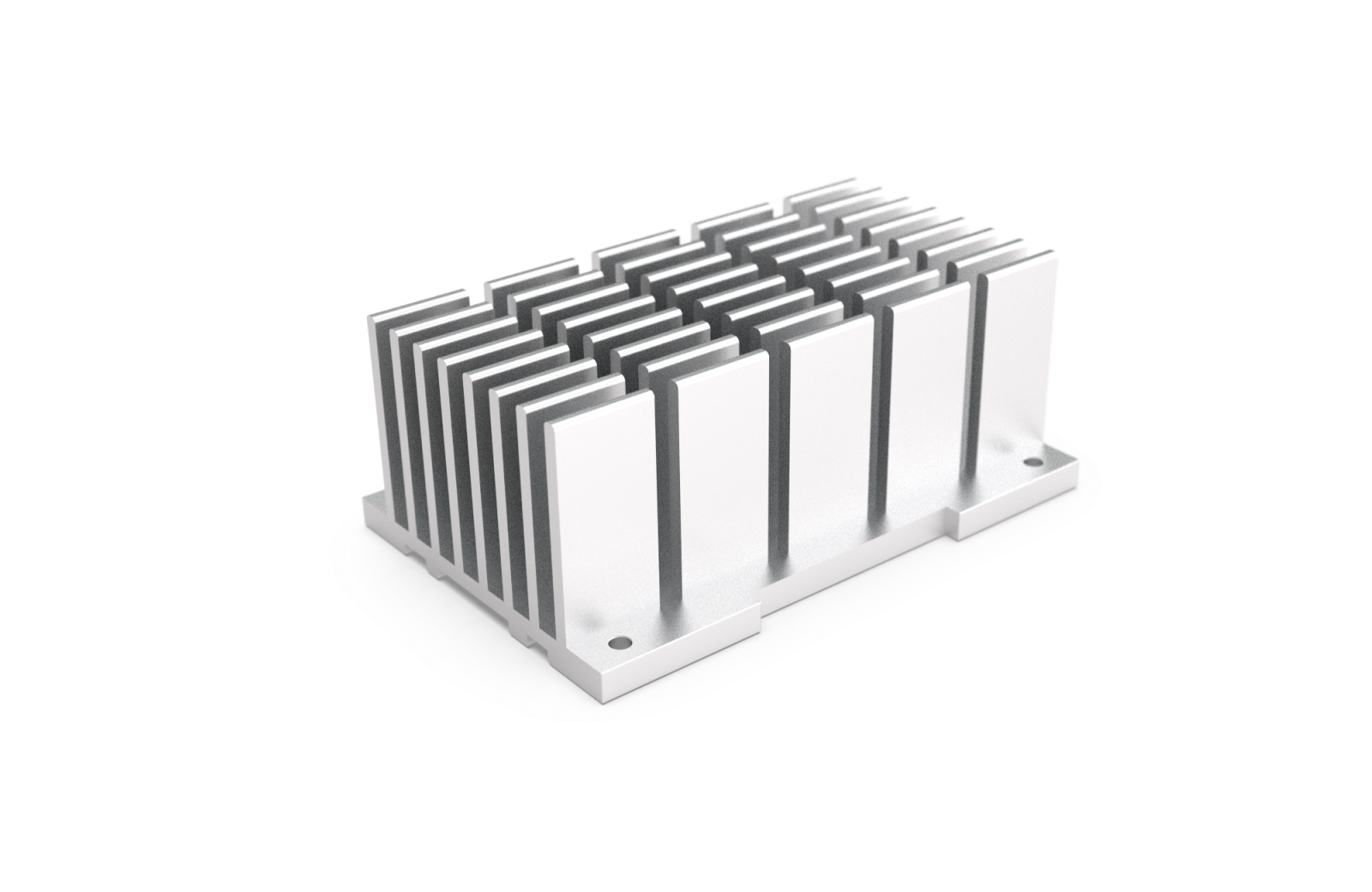

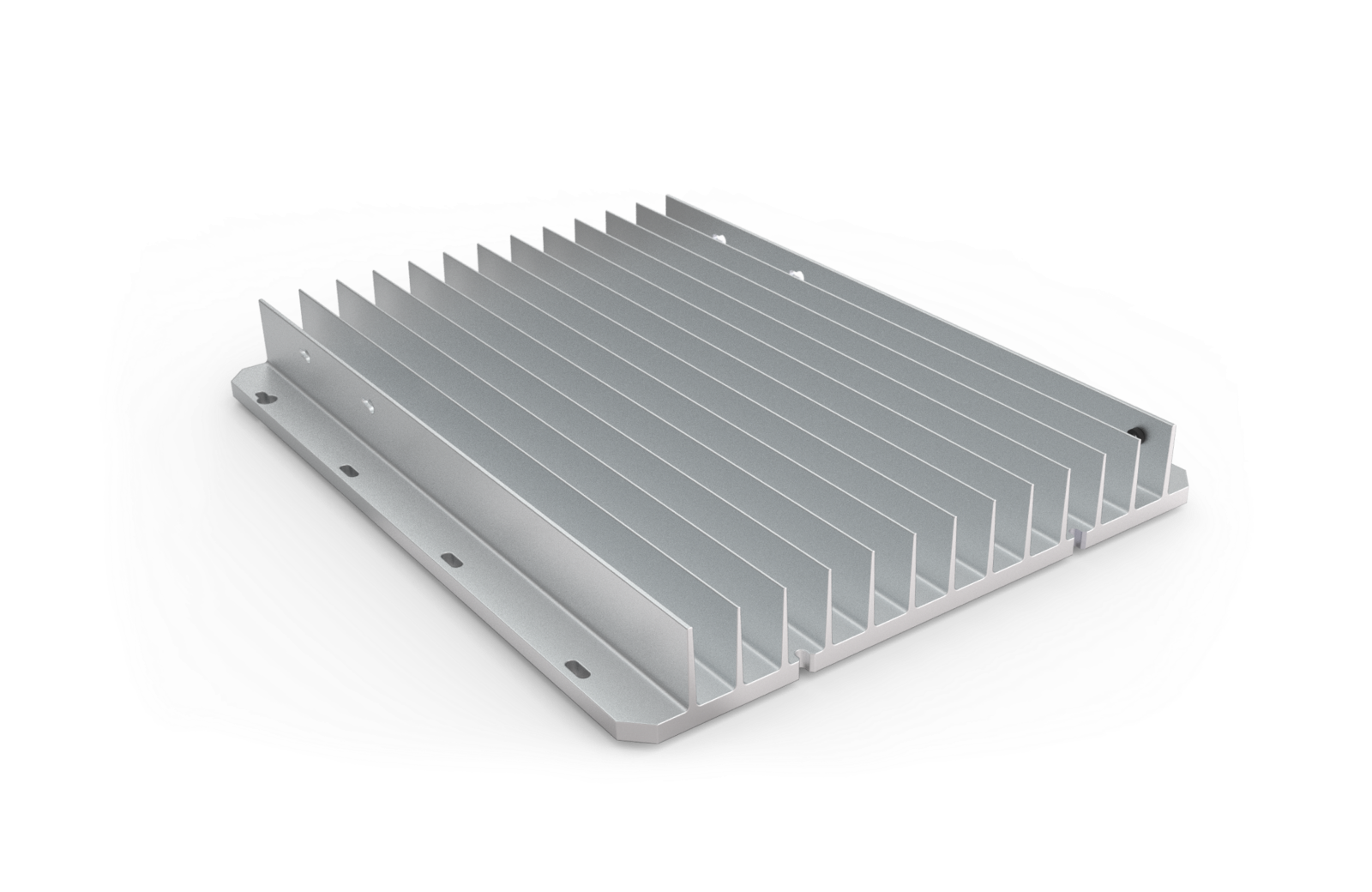

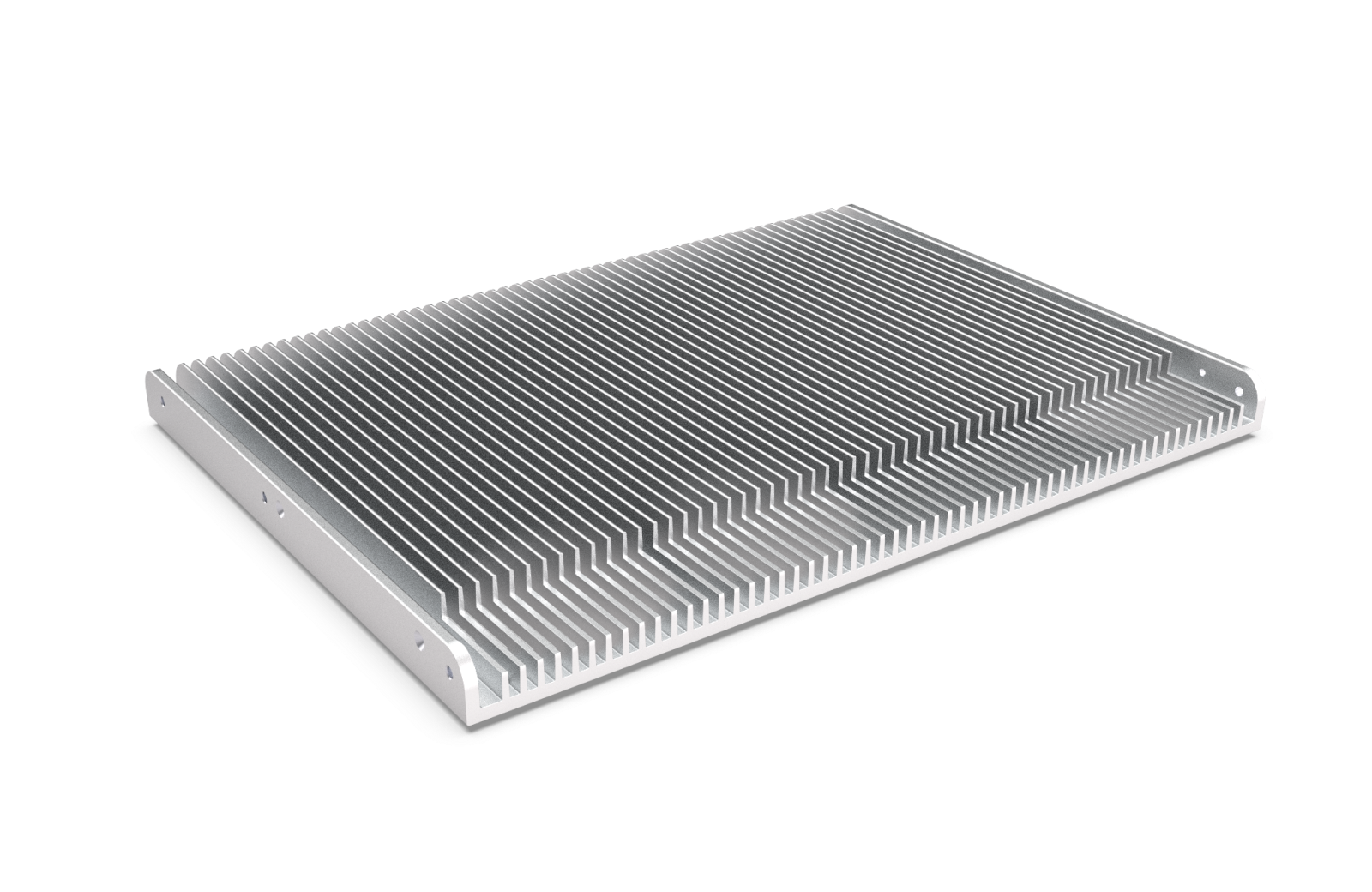

Choose from over 500 proven profiles the right extruded heat sink geometry for your individual requirements.

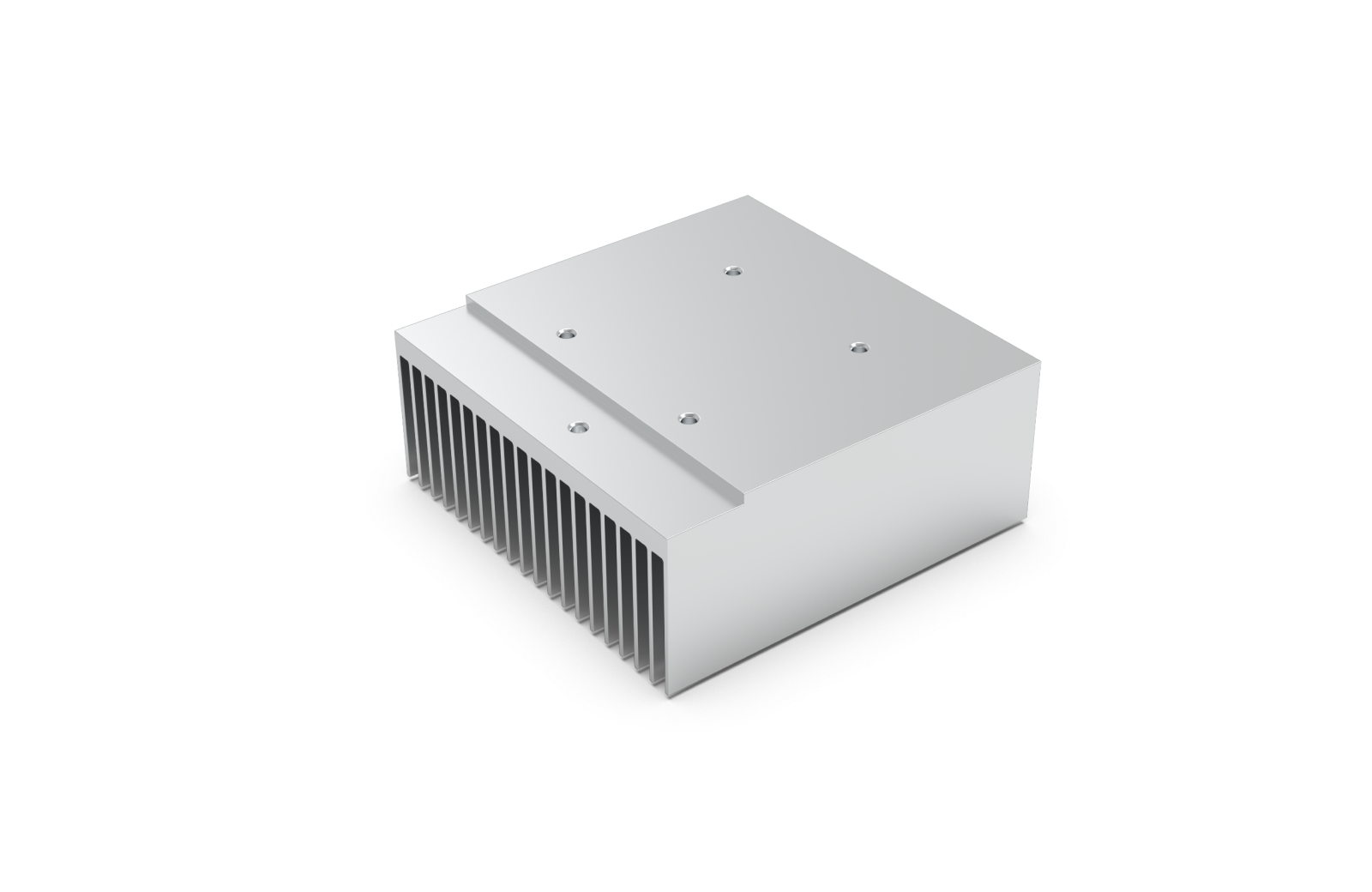

Get in touchExtruded heat sinks made from aluminum-magnesium-silicon alloys EN AW 6060 to EN AW 6063

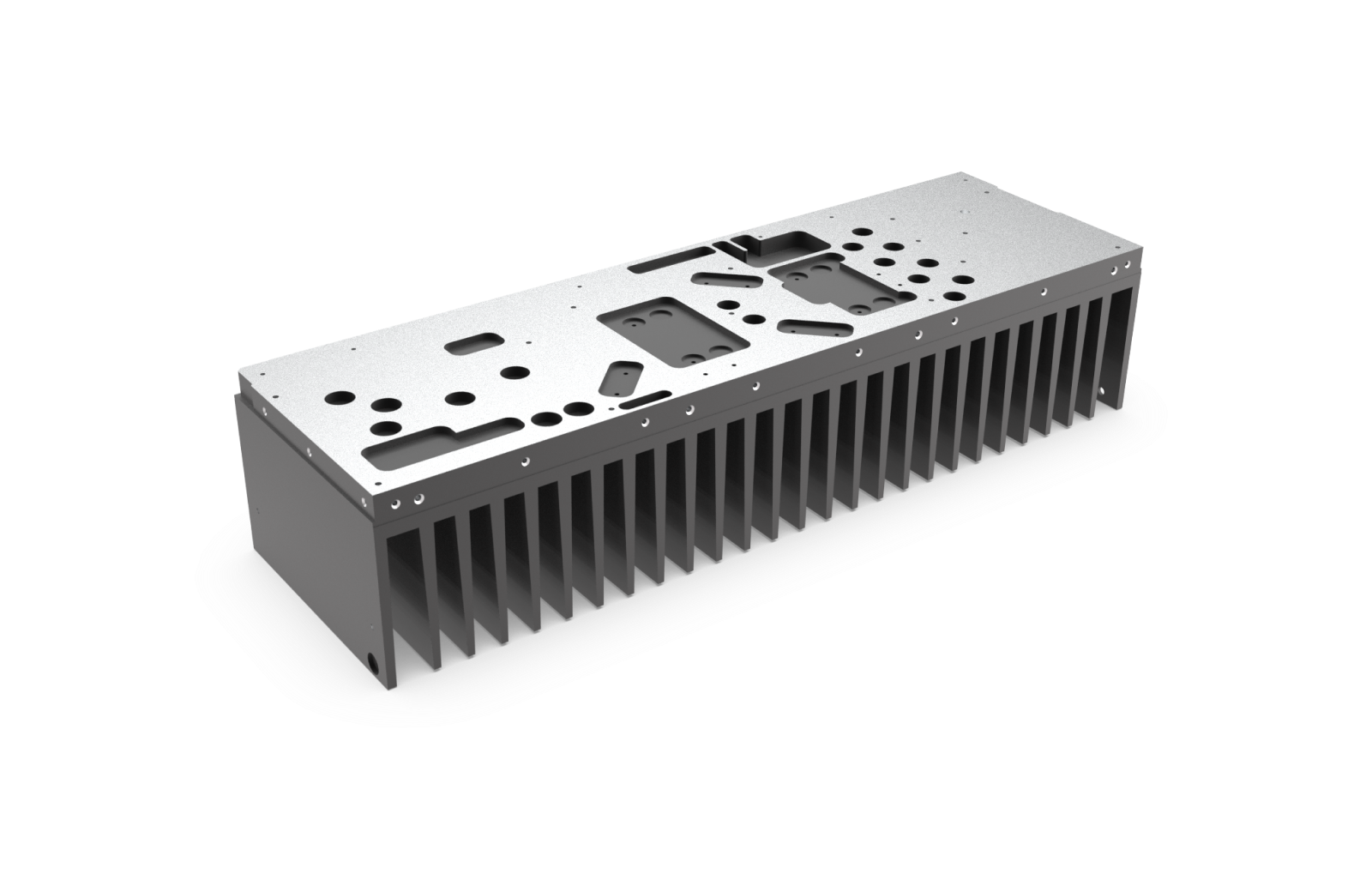

Precision machining up to complete module assembly

Shortest production and delivery cycles thanks to more than 30 semi- and fully automated 3-, 4-, and 5-axis CNC machining centers

Manufacturing of complex heat sinks using in-house welding, soldering, and bonding technologies

Ultrasonically cleaned bare aluminum version, chromium(VI)-free chromating, and decorative anodized surfaces

Electroplated and chemically produced finishes according to MIL standards

Didn't find a suitable profile? We'll create a new custom profile for you with one of our extrusion partners in Europe or Asia.

Go to profile database

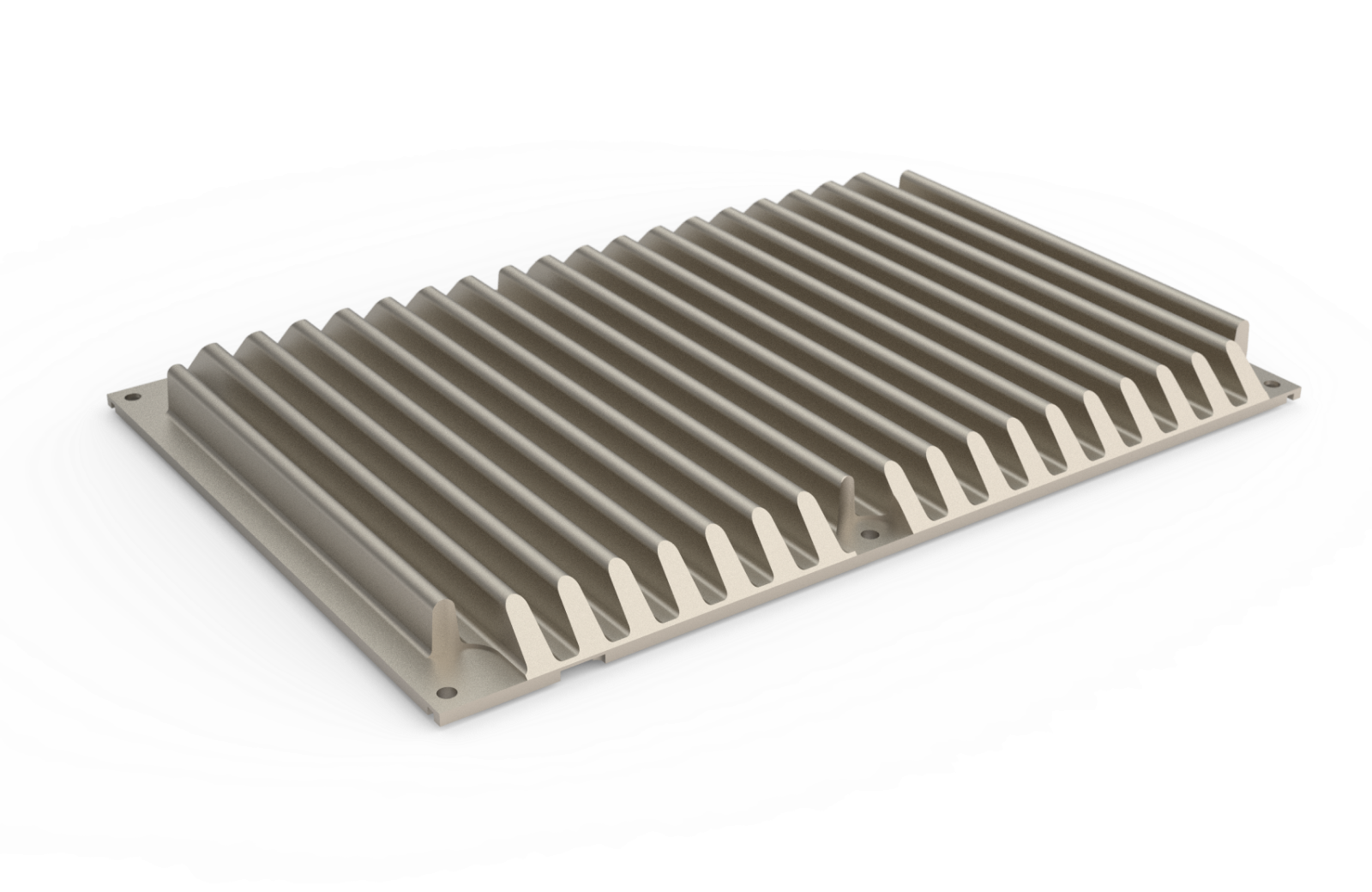

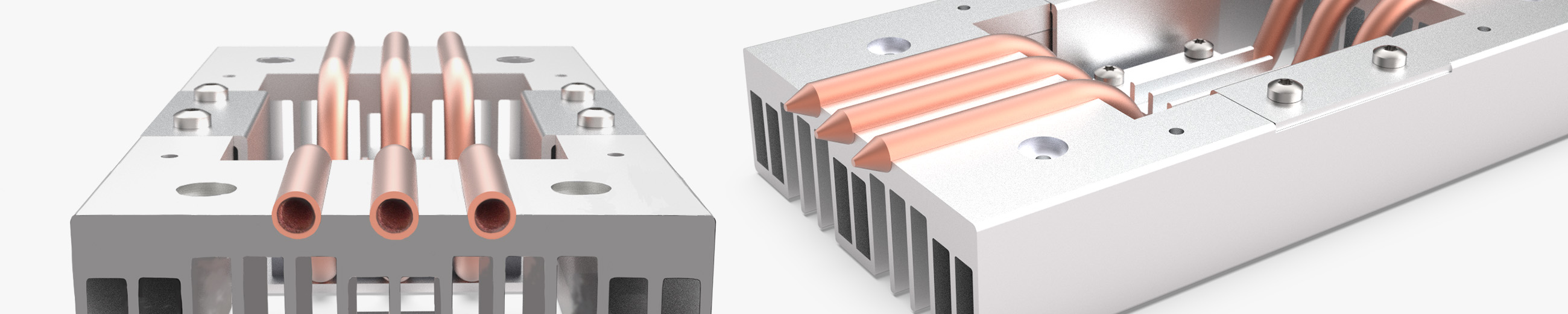

Pressed-in heat pipes significantly improve the cooling performance of extruded heat sinks: They transfer heat very efficiently from the heat source to the cooling fins.

Inside the heat pipe, a working fluid circulates, evaporating when in contact with the hot component and condensing along the pipe. This process distributes heat evenly and releases it via the fins to the surrounding air.

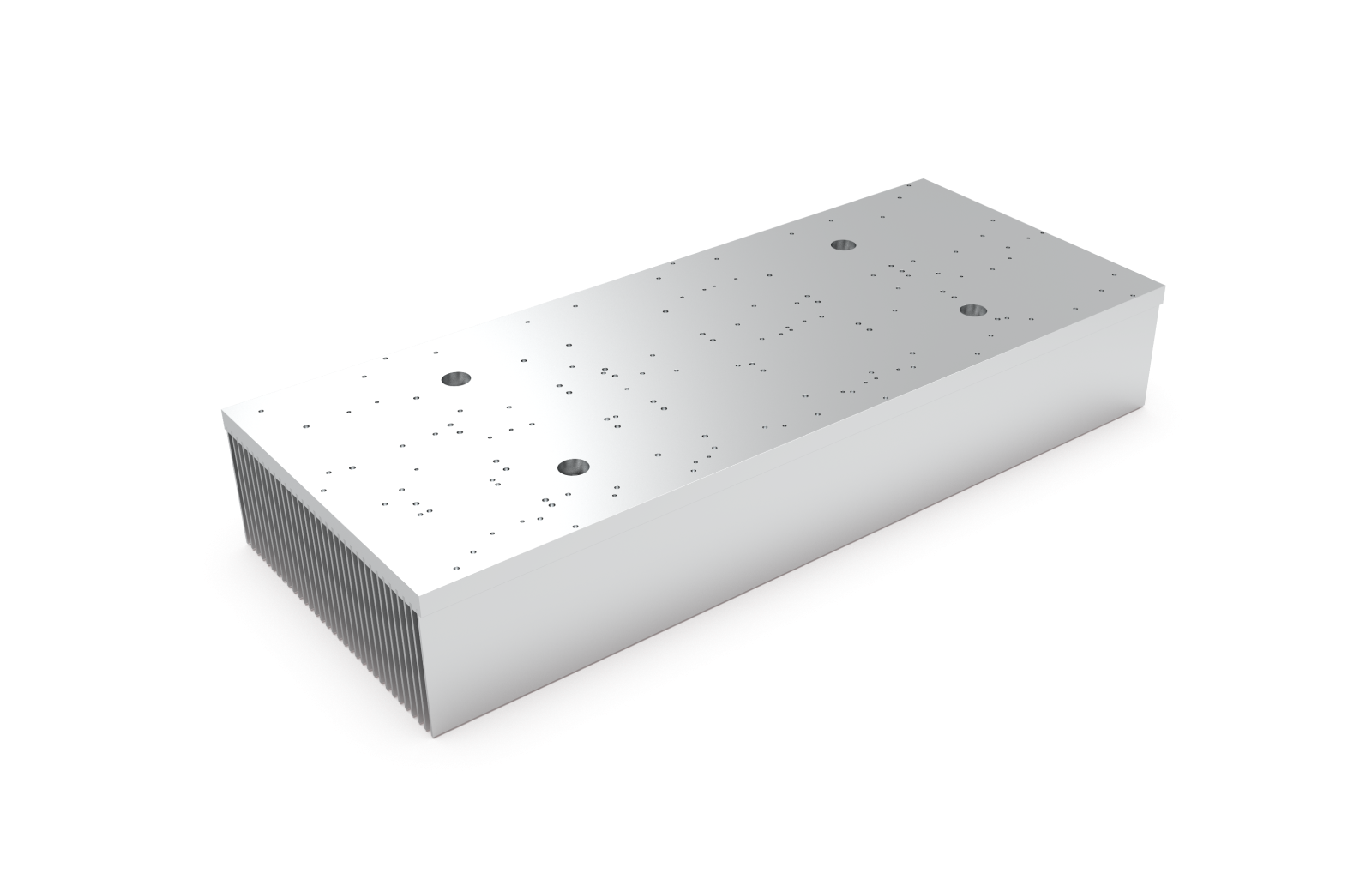

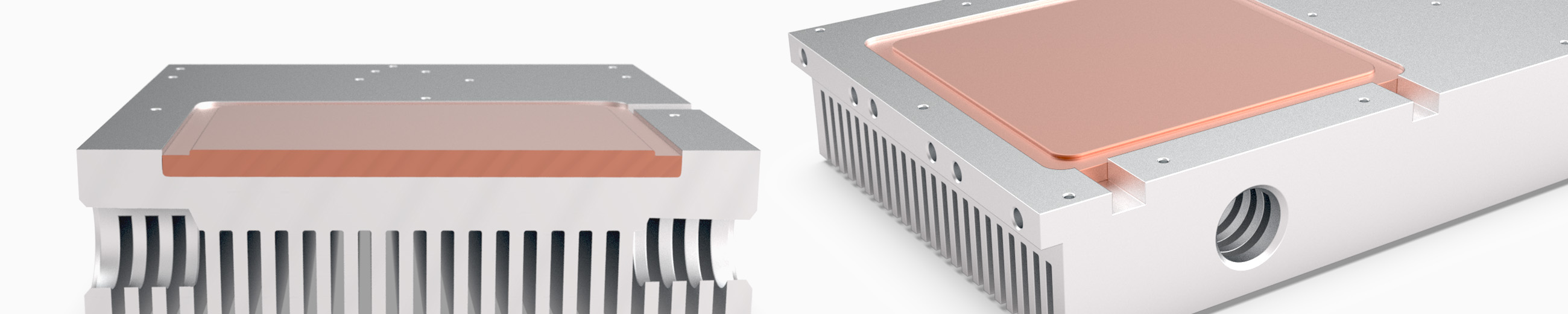

In addition to heat pipes, embedded copper cores are also used – particularly where targeted heat distribution is required.

Copper has a significantly higher thermal conductivity than aluminum and is often integrated beneath fluid channels or highly loaded component areas. This ensures stable operating temperatures, protects sensitive components, and extends the service life of your electronics.

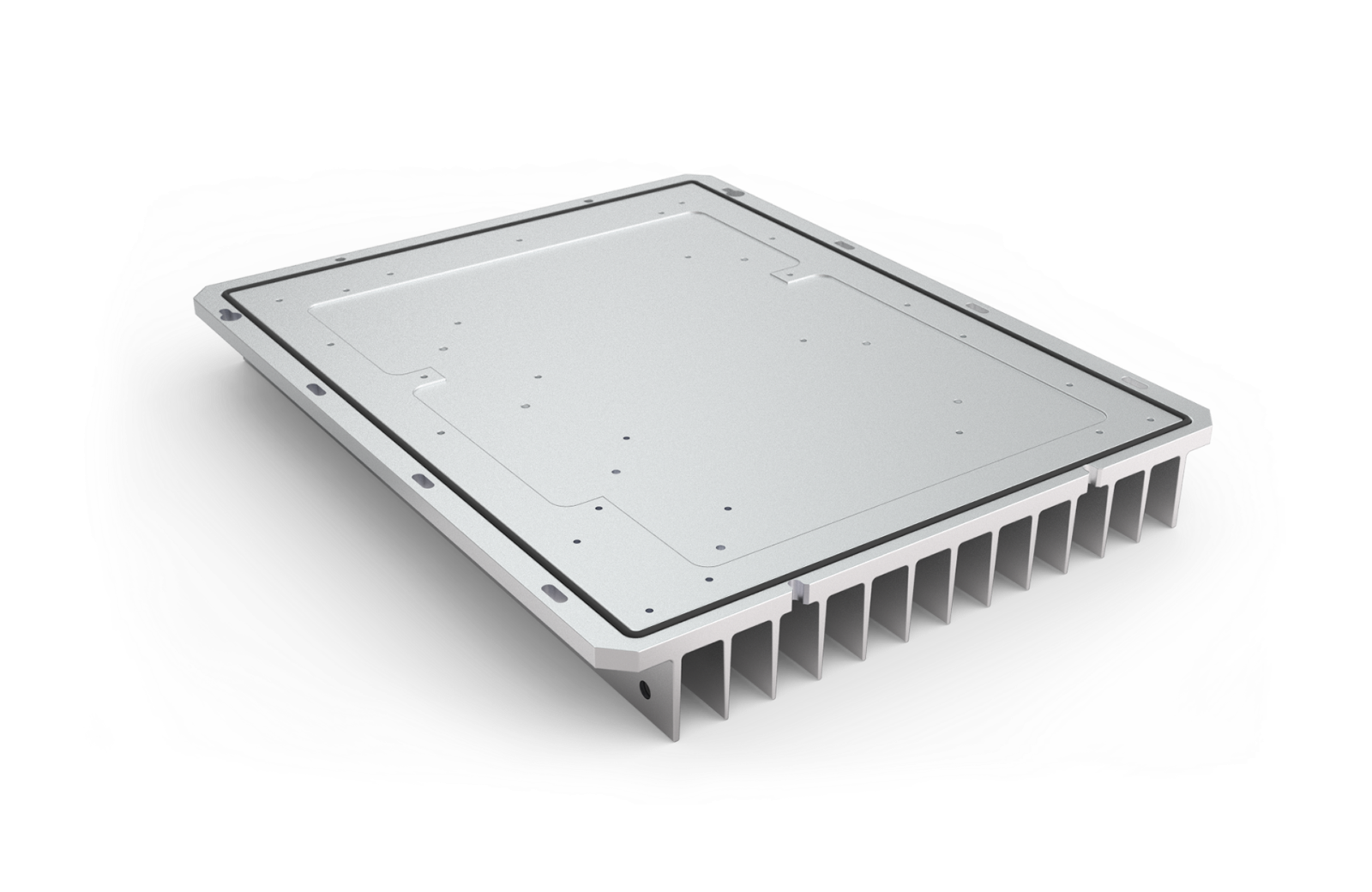

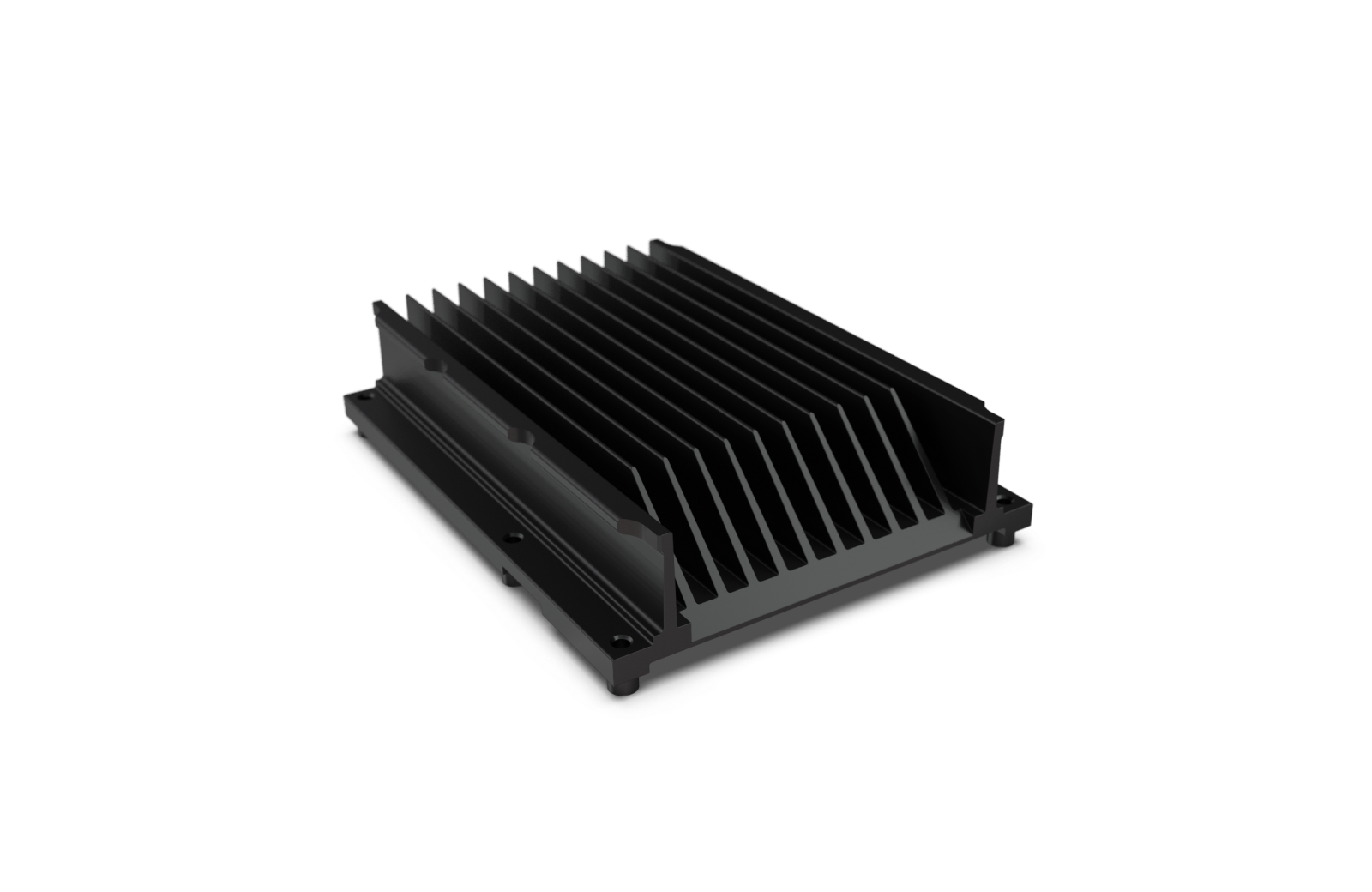

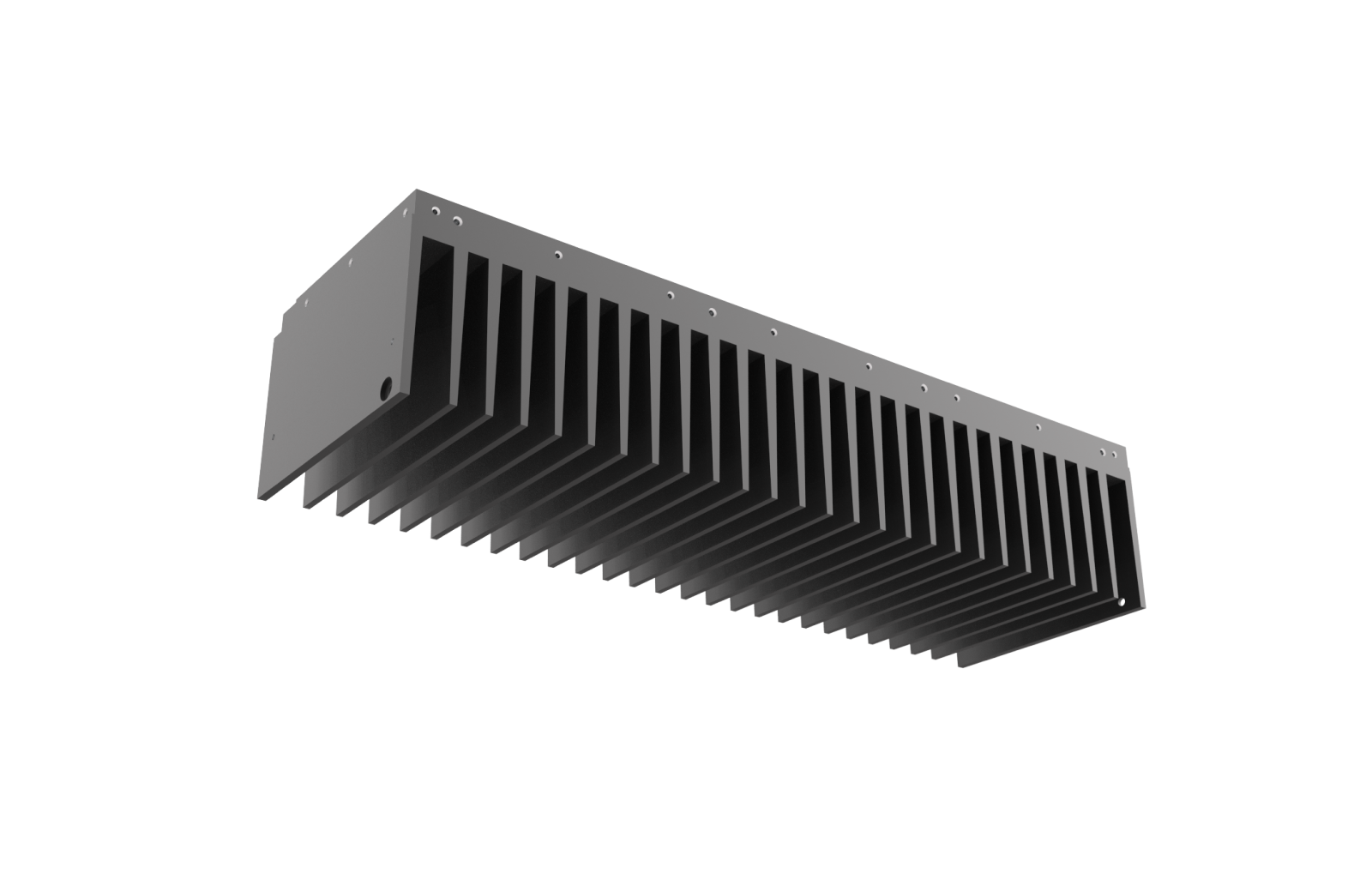

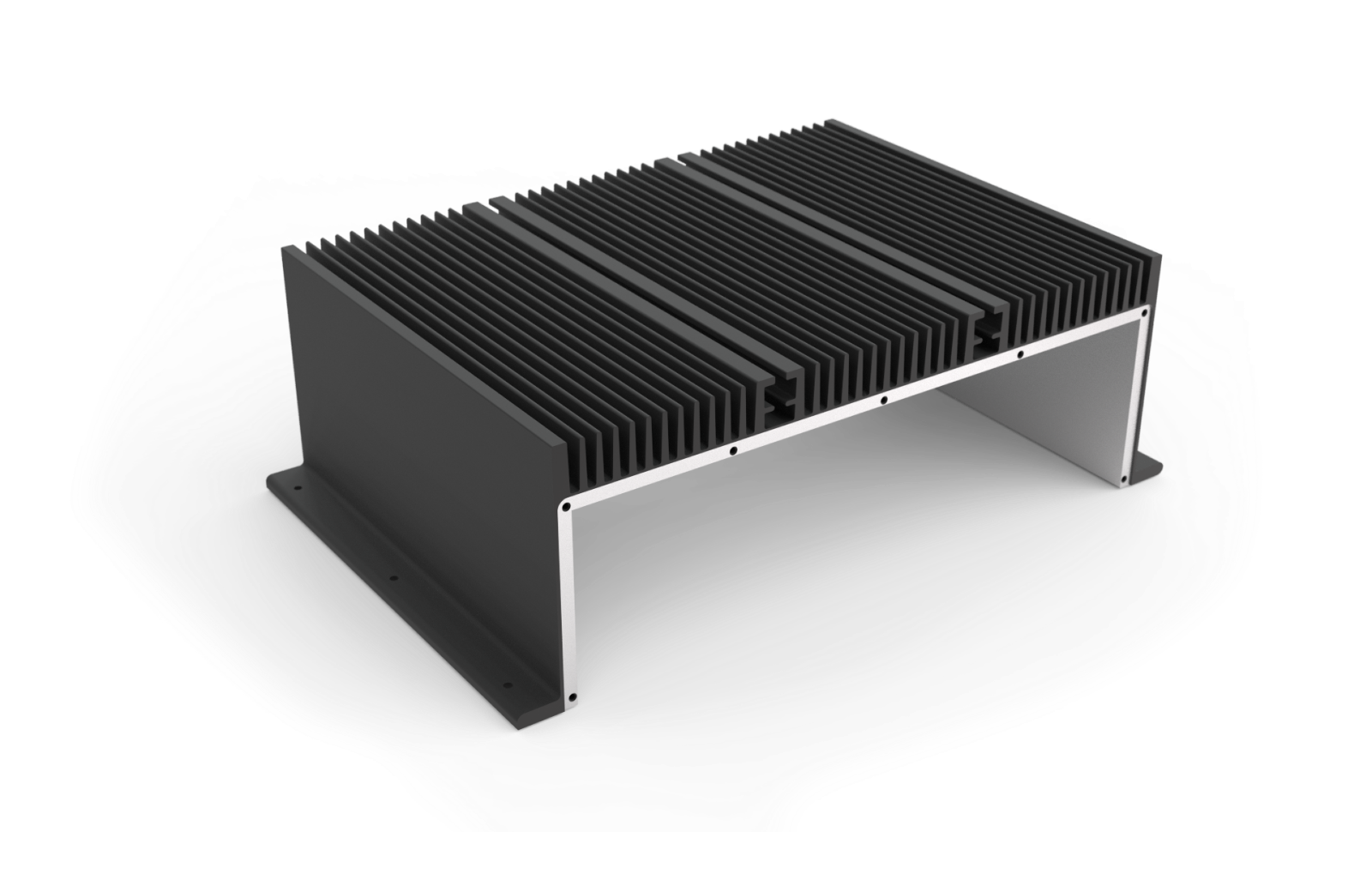

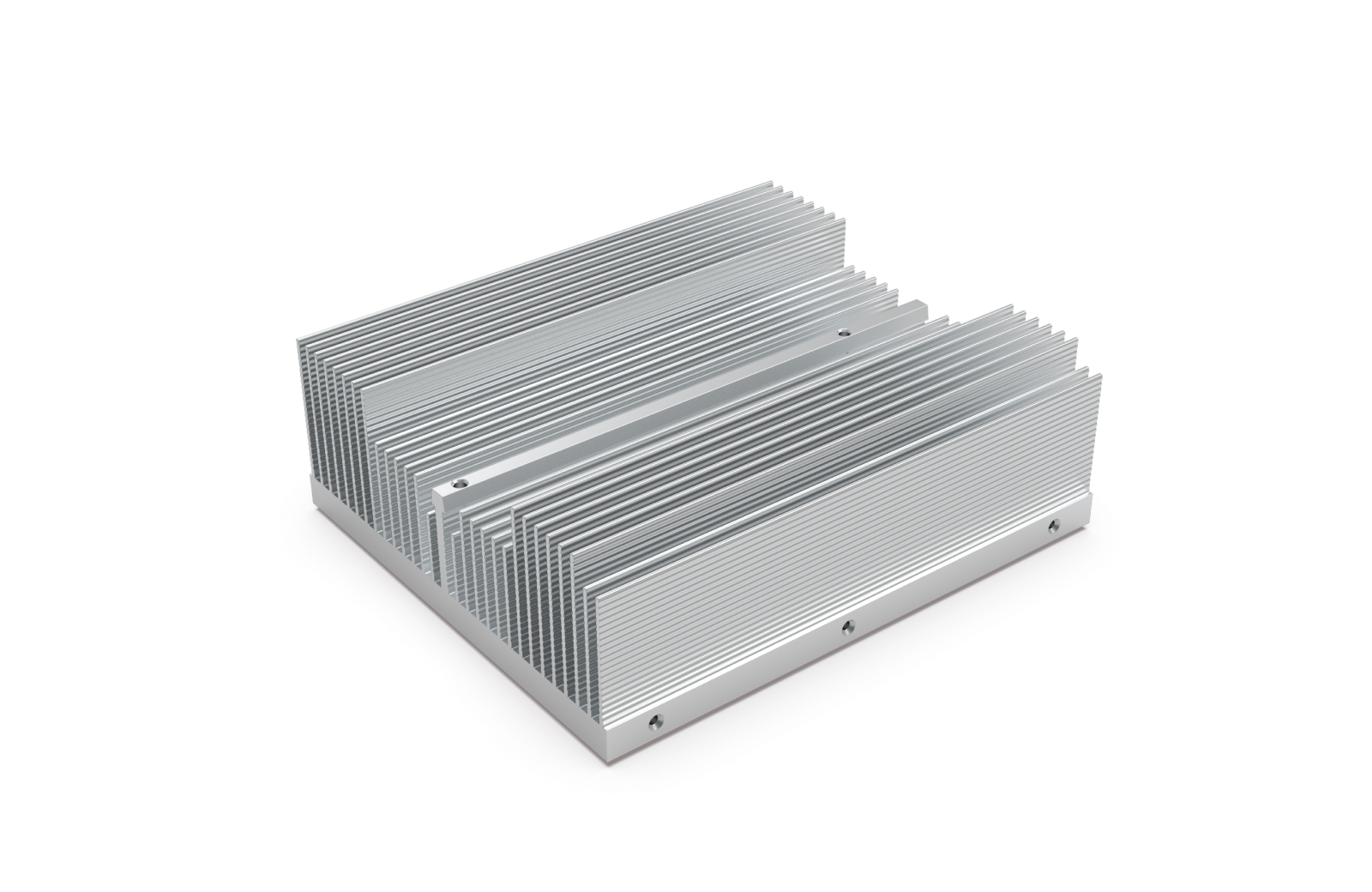

Extruded heat sinks are among the most commonly used solutions for passive heat dissipation in electronic devices. They are manufactured through extrusion, a process in which aluminum is pressed through a pre-shaped die. The result is heat sink profiles with specially designed fin structures that provide maximum surface area for heat transfer – while maintaining high dimensional accuracy and repeatability.

Learn more in a conversation

Efficient passive heat dissipation

High thermal conductivity

Cost-efficient through series production of standard profiles

Flexible geometries & customizable design

Low weight & high stability

Our team supports you in the selection, machining, and performance optimization of your heat sink profile – from the first idea to series production.

Whenever reliable passive cooling is required – for example, in power electronics, LED technology, mechanical engineering, or inverters, control units, and power supplies.

They are particularly cost-effective in series production, allow complex geometries, have low weight, and provide very good thermal conductivity thanks to aluminum alloys such as EN AW 6060 / 6063.

Use our profile database: There you can filter more than 500 available profiles by shape, size, material, and thermal requirements. We are happy to assist you in selecting the right one.

Yes – our CNC centers enable complex machining such as drilling, milling, sawing, or pressing-in of heat pipes. Complete module assembly is also possible.

Heat pipes transfer heat rapidly through phase change (evaporation/condensation), while copper inserts distribute heat evenly within the heat sink. Both technologies enhance cooling performance and can be combined.

Our extruded heat sinks are produced at our sites in Großbreitenbach and Kaltennordheim, Germany – ensuring short delivery times and the highest production depth.

That depends on the profile, processing, and quantity. Standard profiles are cheaper than custom designs. We will gladly provide you with a suitable offer – just contact us.

Then we will work with you to develop a custom profile – optionally with new tooling in cooperation with our extrusion partners in Europe or Asia.