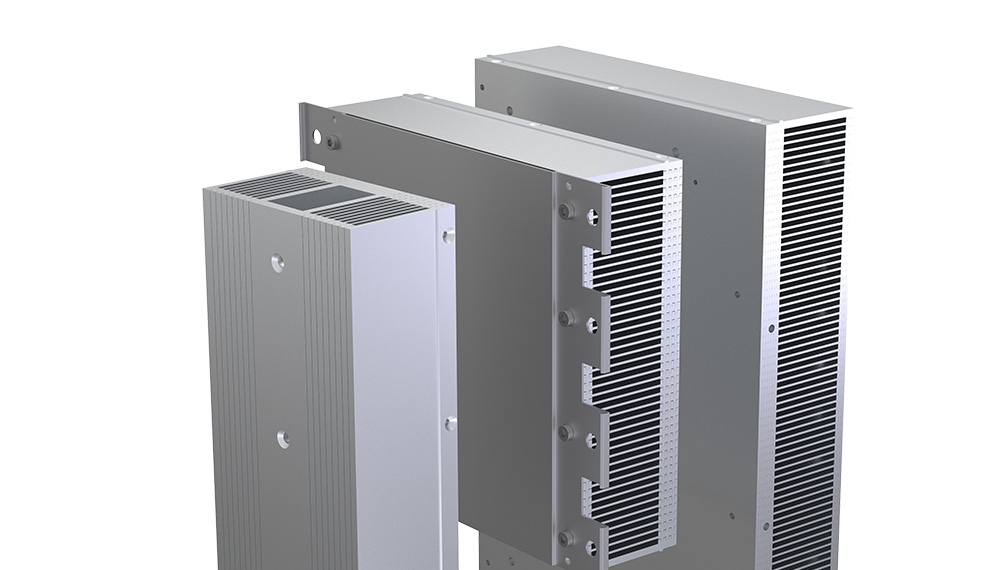

Side Pressed Fin Heat Sinks

Learn how our product family enables small fin spacing and double-sided component mounting and cooling – for compact, high-performance cooling solutions.

Whether aluminum, copper, or stainless steel – we select the optimal material for each heat sink to ensure maximum thermal conductivity, stability, and durability.

Aluminum is the preferred material for manufacturing heat sinks and liquid cooling plates in power electronics. It offers excellent thermal conductivity, low weight, and high corrosion resistance, making it ideal for a wide range of cooling applications.

Learn more

Copper provides extremely high thermal and electrical conductivity – about twice that of aluminum. This allows for highly efficient heat dissipation, ideal for applications with high power density and limited space.

Learn more

Stainless steel is used for its outstanding corrosion resistance and mechanical strength. It is particularly suitable for applications under harsh environmental conditions or where stability and longevity are critical.

Learn more

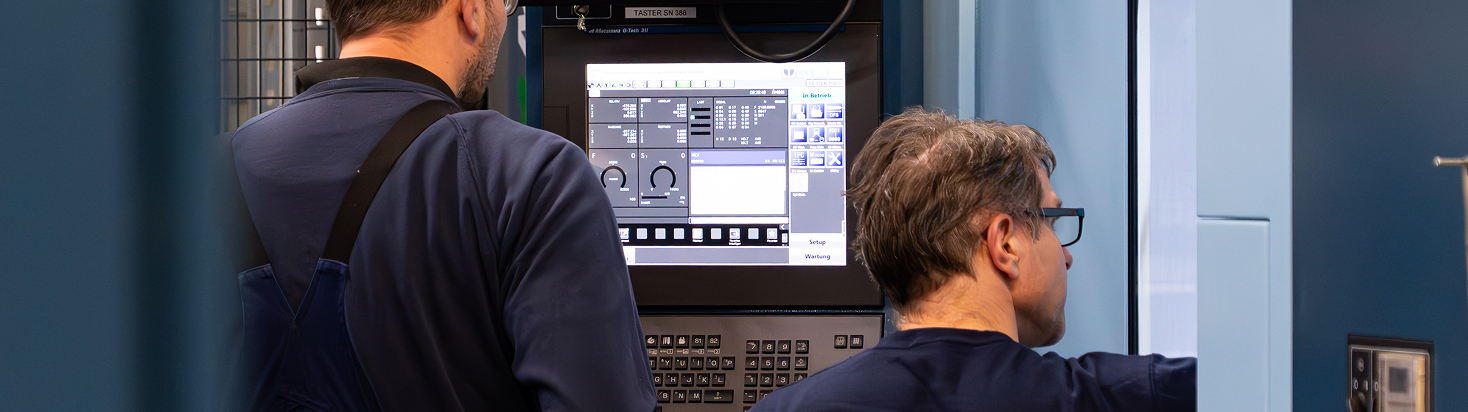

...and discover how much passion, experience, and precision go into every one of our cooling solutions – from development to the finished product.

Learn moreOur experts provide personalized advice on the selection of aluminum, copper, or stainless steel – for heat sinks that are efficient, durable, and precisely tailored to your needs.

Learn how to optimize cooling for high-tech applications – with solutions that are efficient, reliable, and ready to implement.

Download report