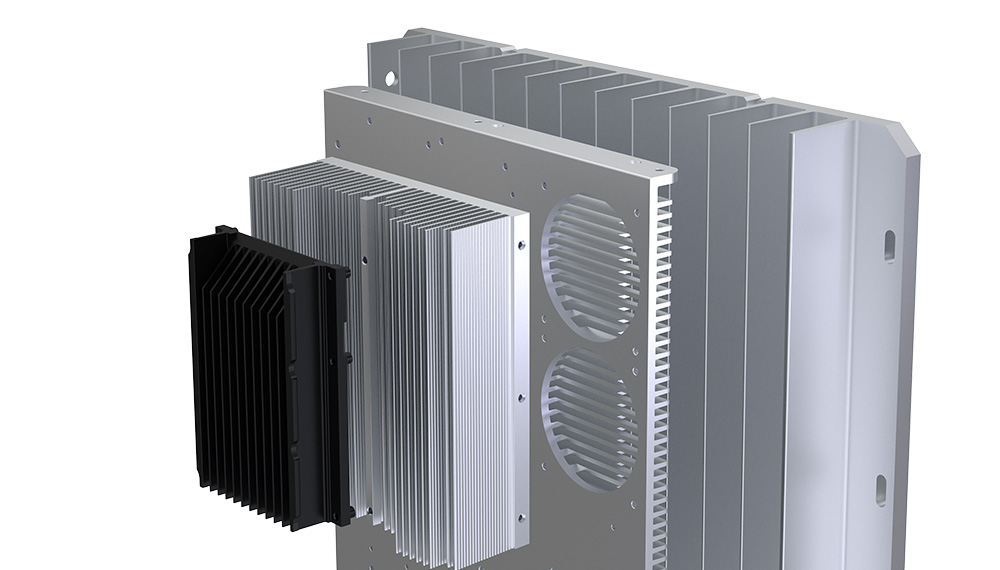

Extruded Heat Sinks

Find out how our extruded heat sinks can optimally support your application as well.

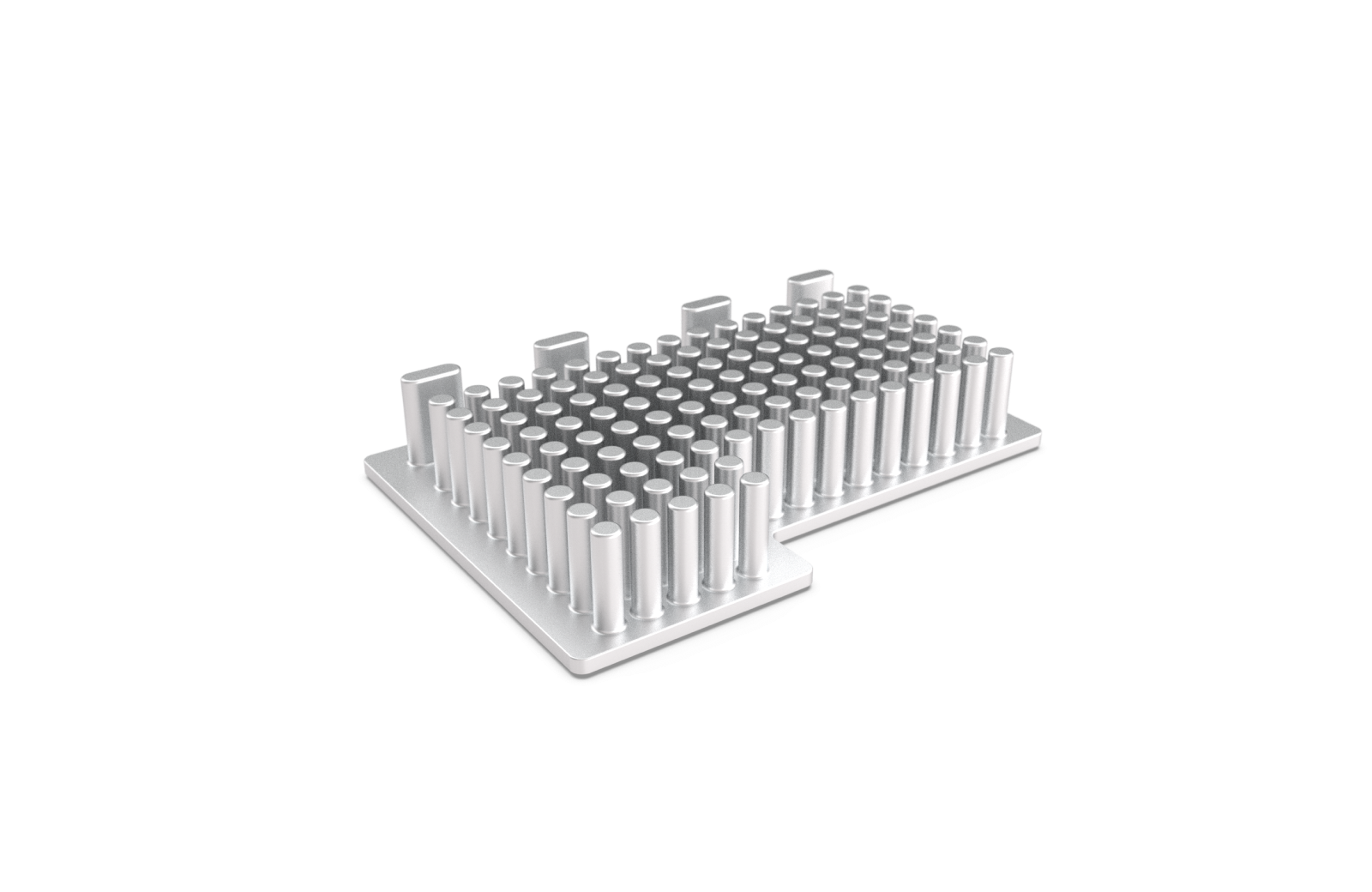

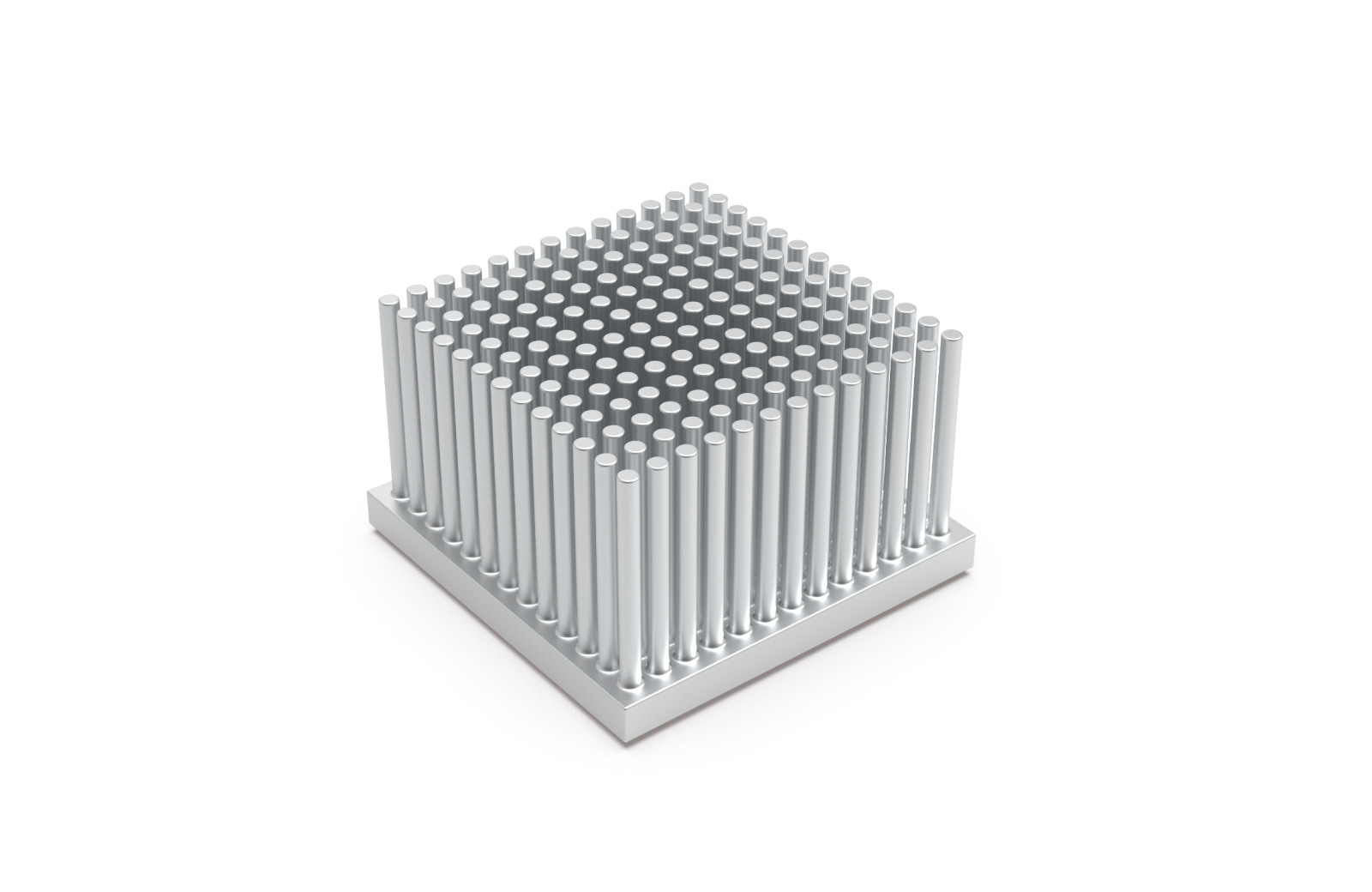

Pinfin heat sinks with round or square pins provide excellent convection performance and are particularly suitable for limited installation spaces.

Contact usCross and diagonal airflow for maximum cooling performance

Highly effective in confined spaces

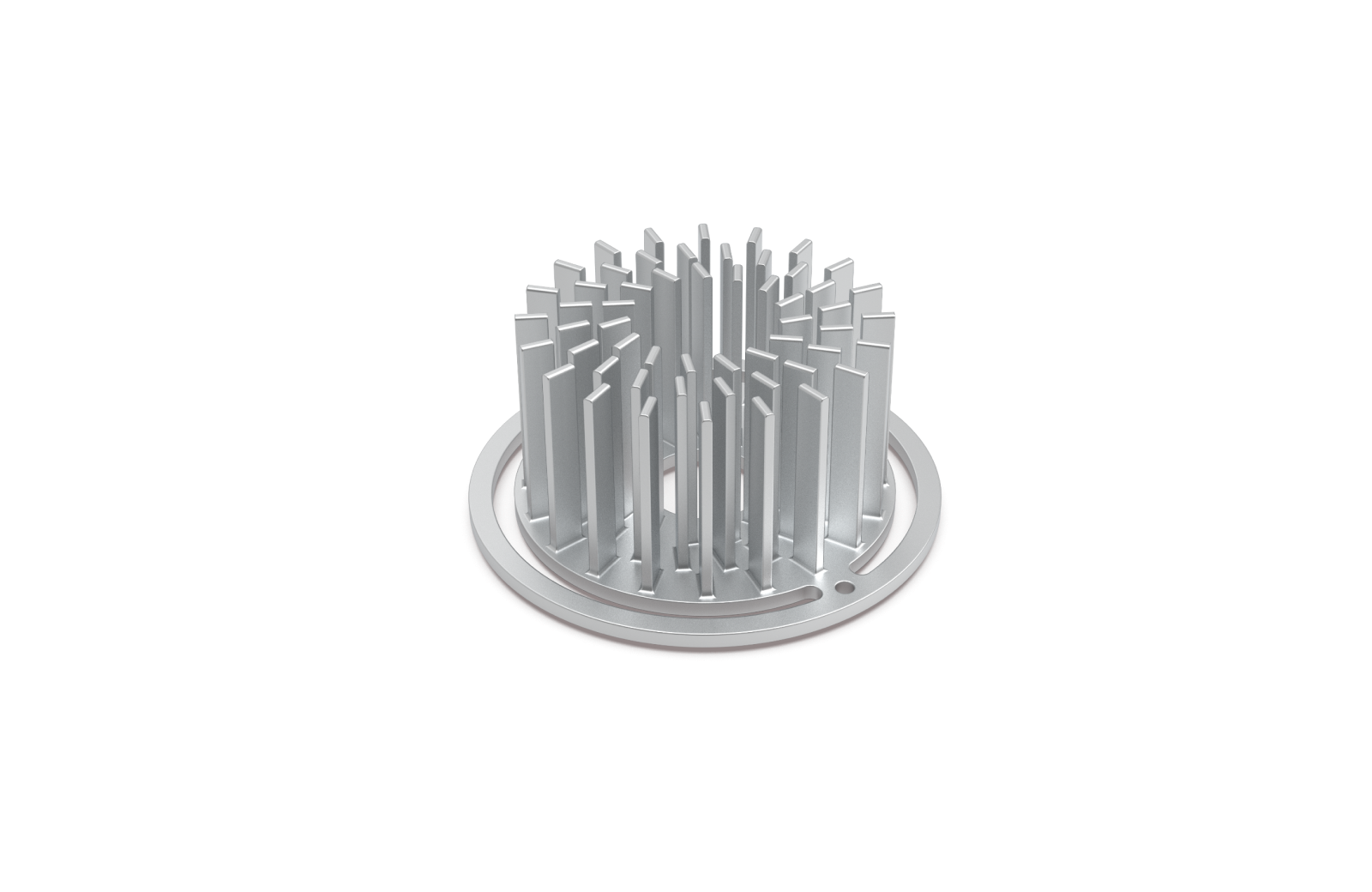

Ideal for cooling LED components

Low tooling costs enable virtually unlimited design variations

Compact and perfectly adapted geometries

EN AW-1050A with 99.5% aluminum content

Formed using cold and flow-pressing techniques

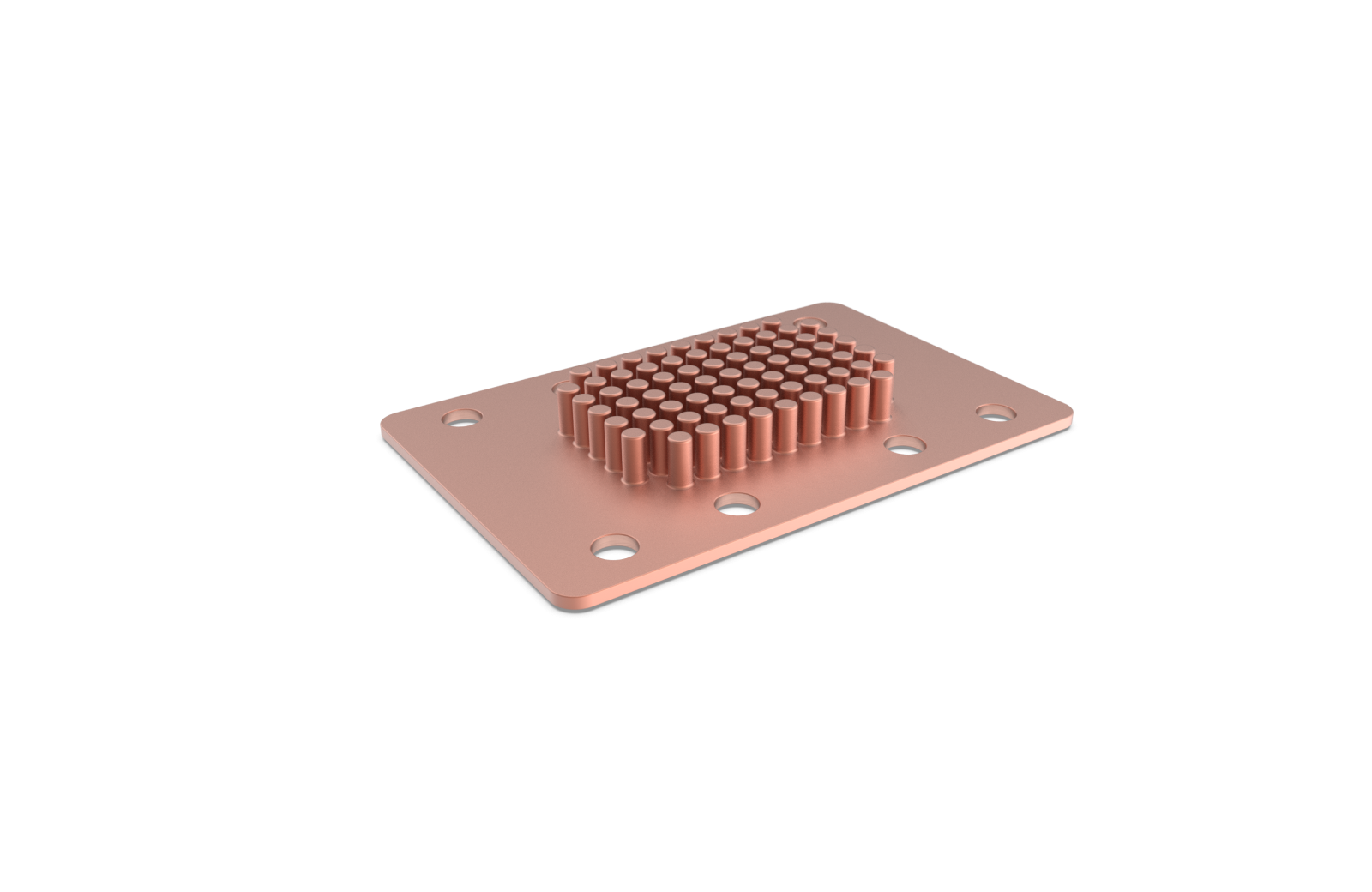

Also available in copper alloys for improved thermal conductivity

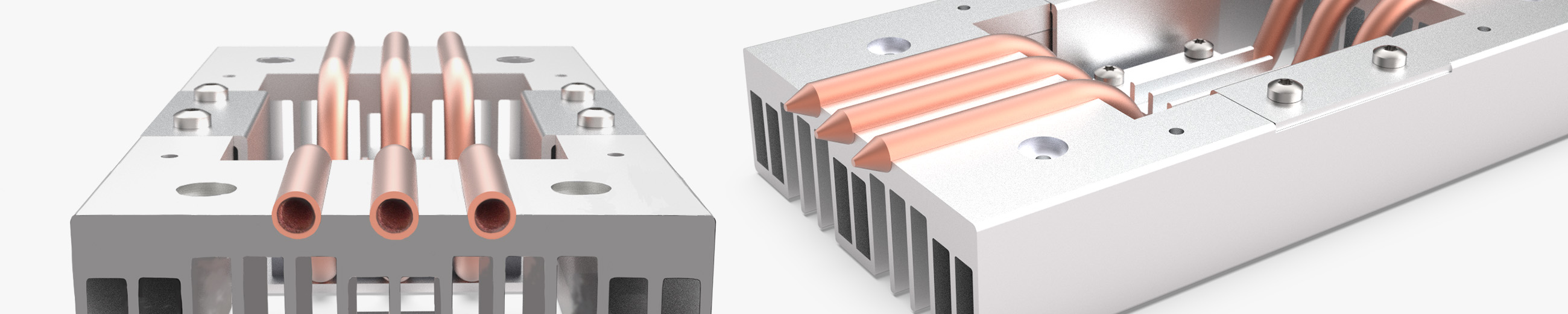

Integrated heat pipes accelerate heat transfer from critical hotspots to the cooling fins. Through a closed loop of evaporation and condensation, heat is evenly distributed – effectively supporting both passive and active air cooling systems.

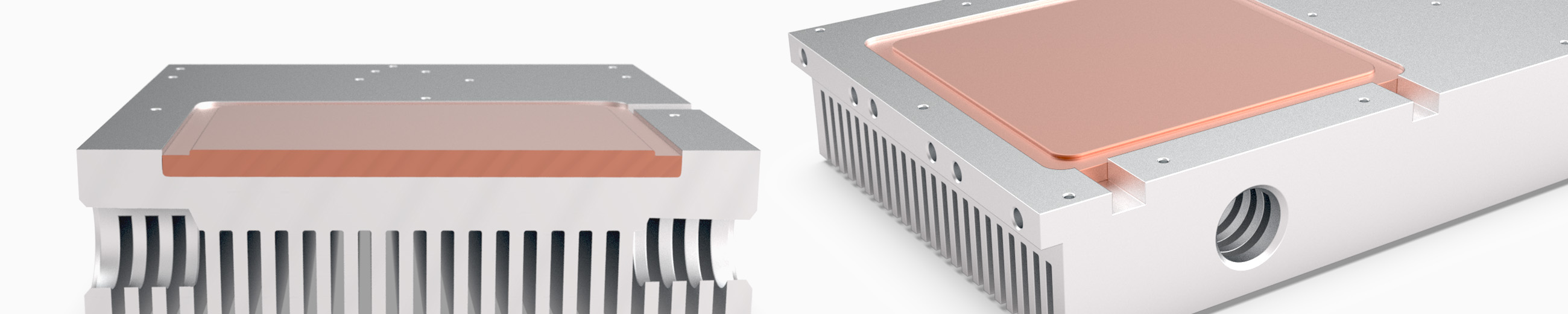

Copper inserts ensure uniform temperature distribution throughout the heat sink thanks to their excellent thermal conductivity. This minimizes local overheating and enhances thermal stability under heavy loads.

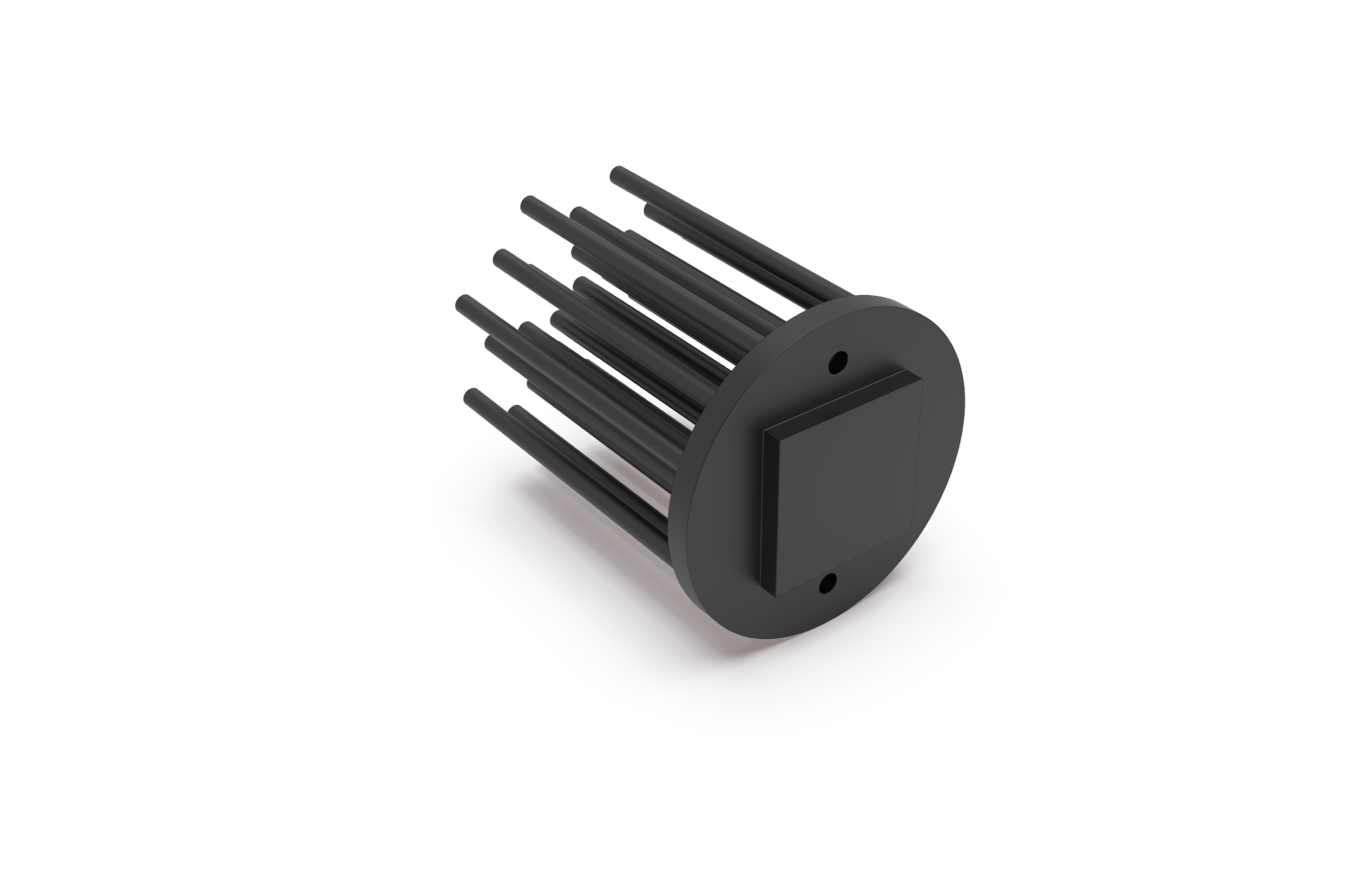

Pinfin heat sinks are cold-forged air-cooling components with vertically oriented pins that create a particularly large surface area. This structure enables efficient convection – ideal for compact designs and multidirectional airflow applications.

The cold-forging process allows complex geometries with high material density. Combined with excellent thermal conductivity (e.g., aluminum EN AW-1050A or copper alloys), it results in a portfolio of cooling solutions that meet the highest thermal demands in the tightest spaces.

Learn more in a consultationMaximum cooling performance in the smallest space

Optimized for cross and diagonal airflow

Wide material selection: pure aluminum & copper

Cost-efficient thanks to low tooling costs

Flexible pin geometries – fully customizable

Our engineering team supports you quickly, individually, and precisely in the development and selection of the ideal heat sink.

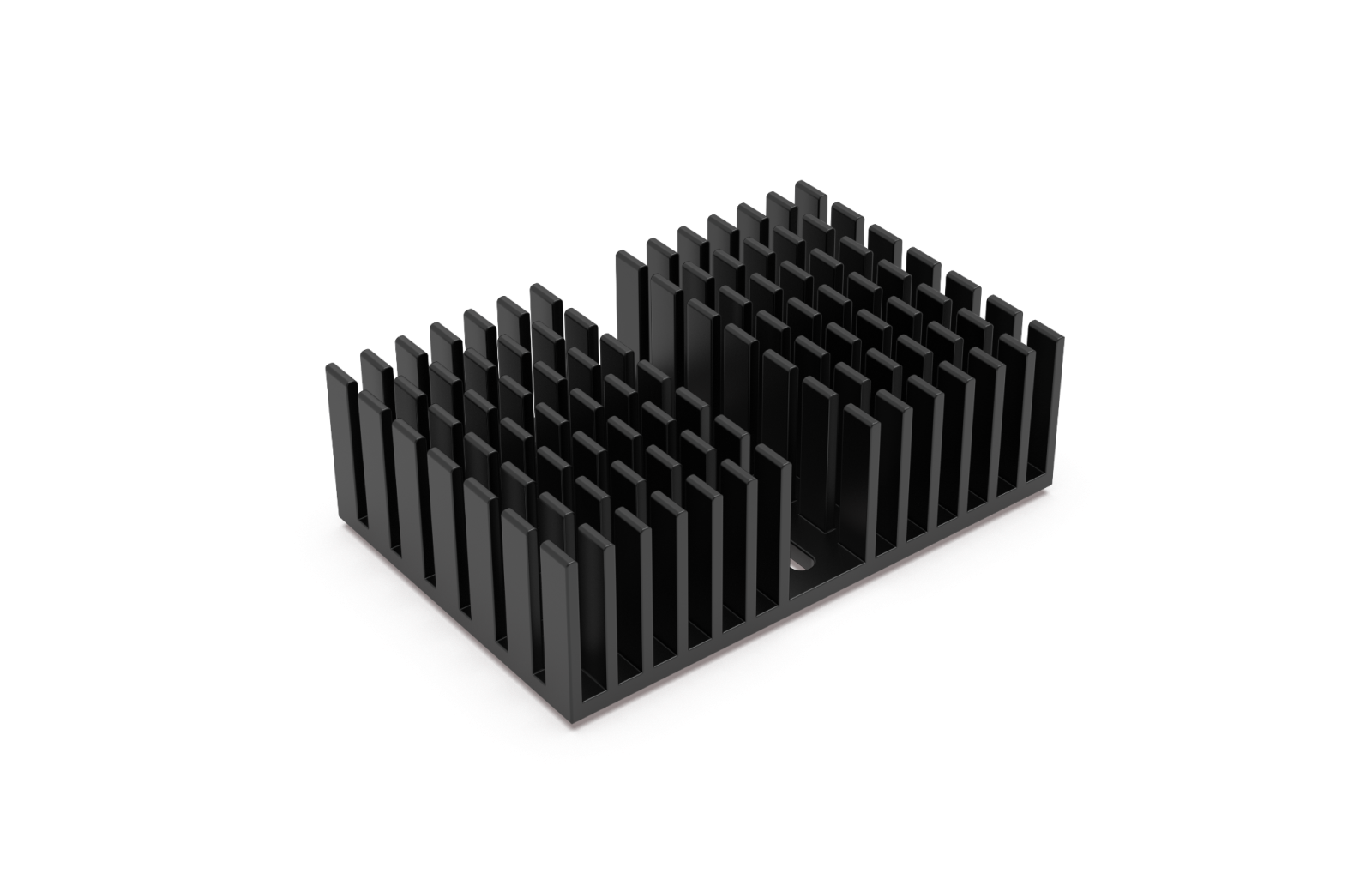

Cold-forged heat sinks are made from aluminum profiles shaped using the cold-forging process. This method allows complex geometries with increased surface area for efficient heat dissipation.

The heat sinks feature thin fins or pins that provide a large surface area. The increased contact area with air improves convection and enables efficient heat removal from electronic components.

They offer high thermal performance, compact design, and flexible geometries. Cold forging allows for precise and varied shapes, making them ideal for applications with limited space.

The integration of pressed-in heat pipes and copper inserts as heat spreaders ensures faster and more uniform heat distribution, reducing hotspots and extending the lifespan of electronic components.

They are ideal for LED lighting, control electronics, power electronics, and industrial automation – especially where high thermal performance is required in compact designs.