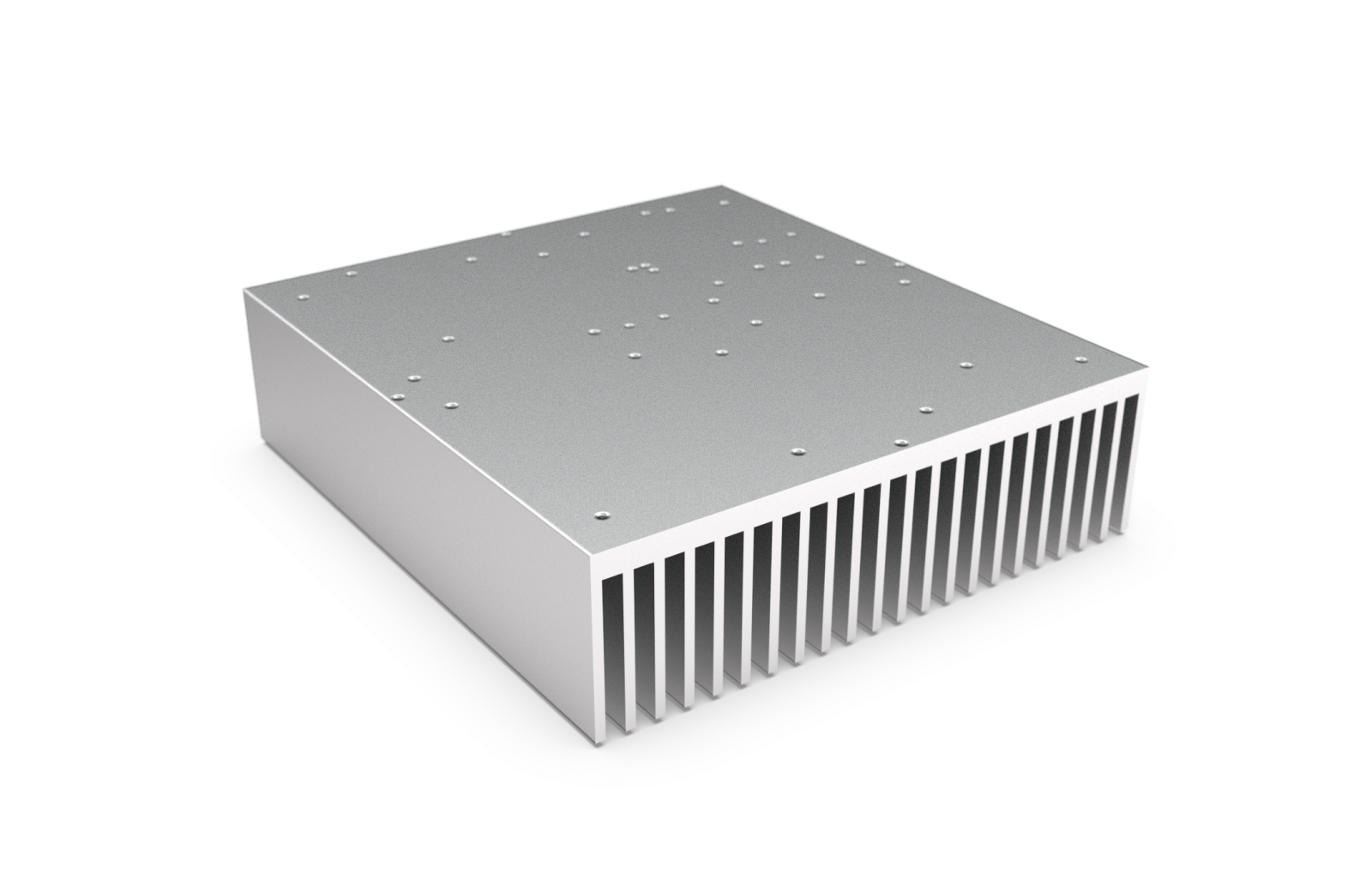

Extruded Heat Sinks

Find out how our extruded heat sinks can optimally support your application as well.

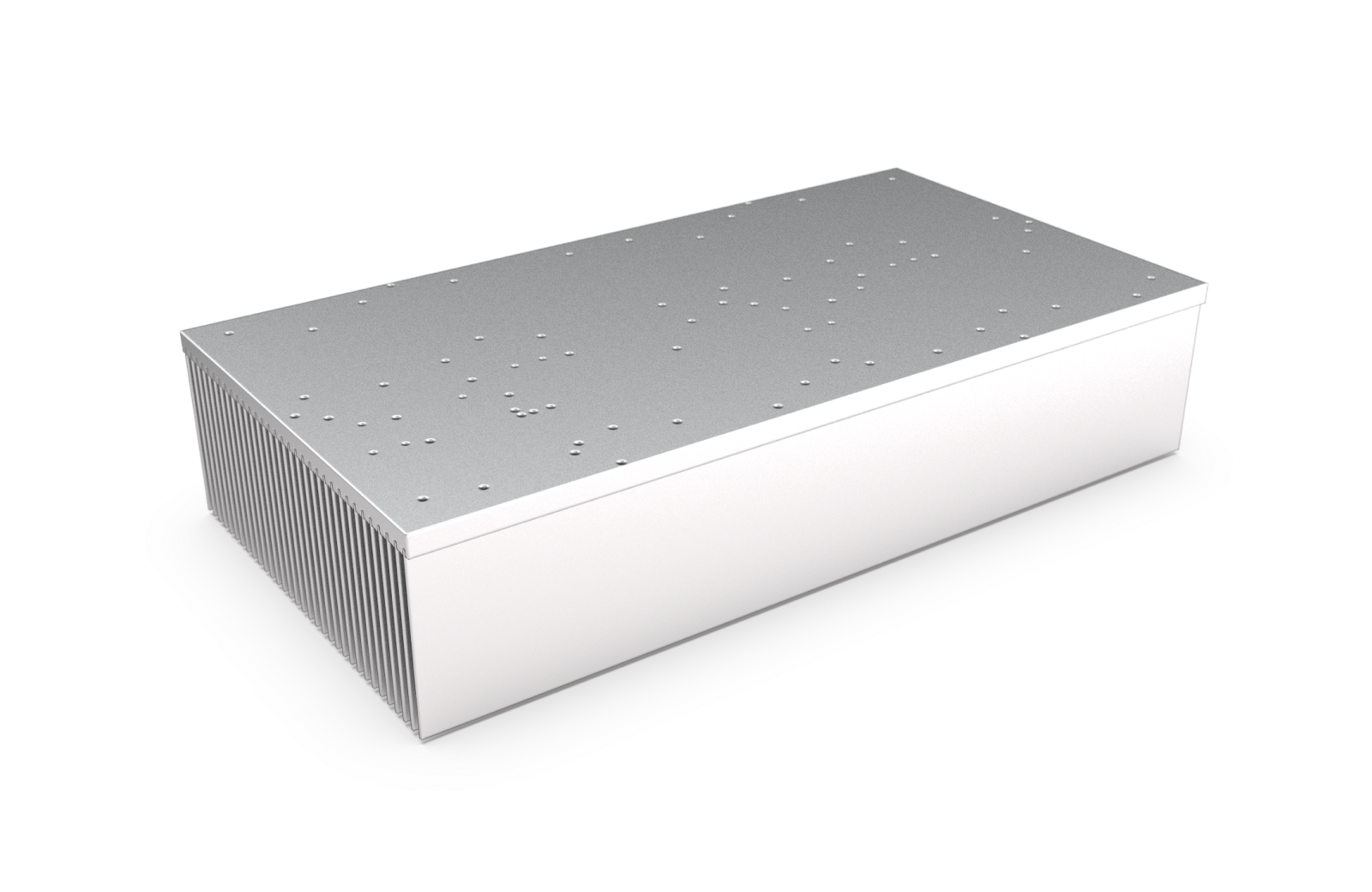

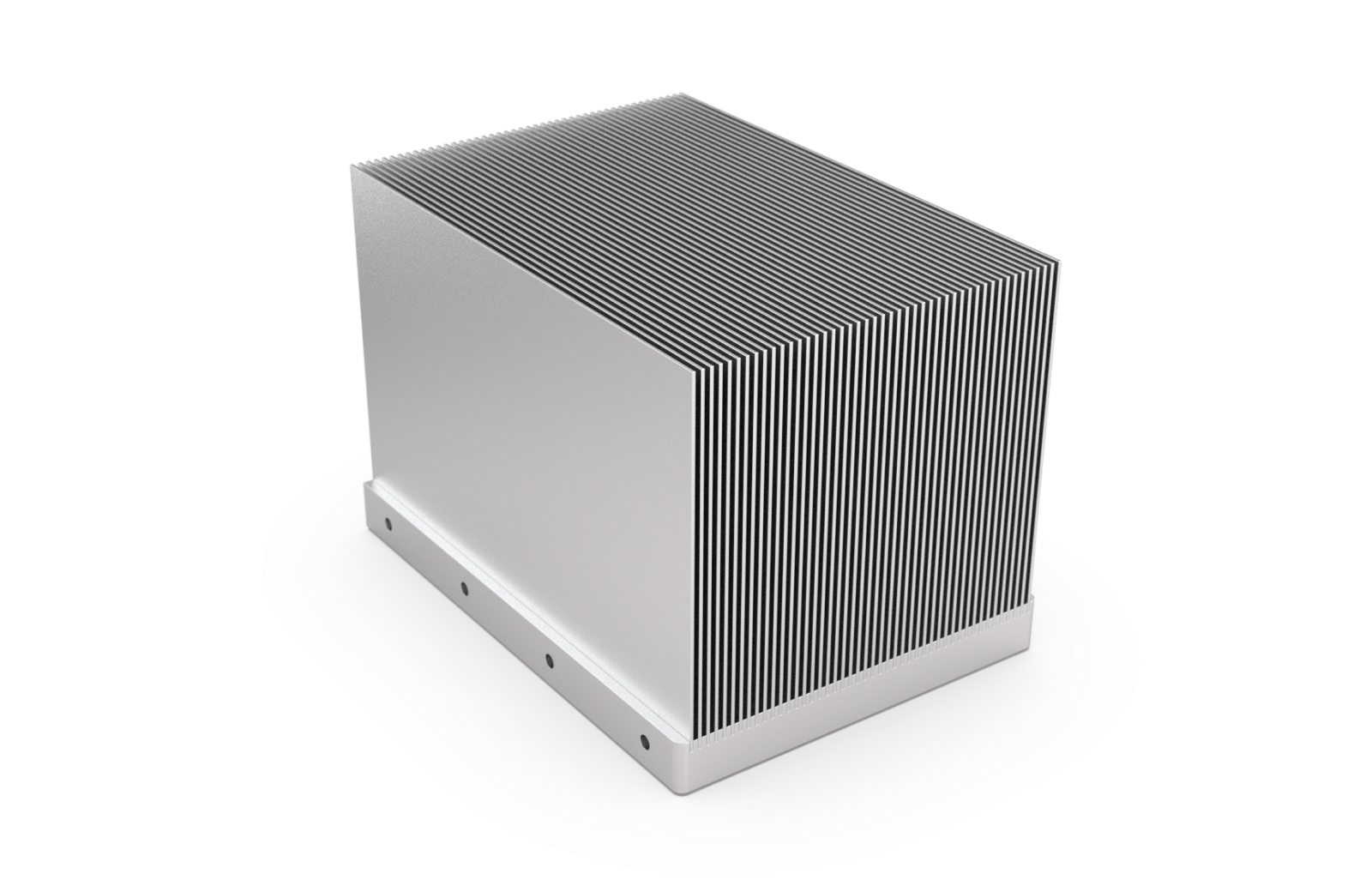

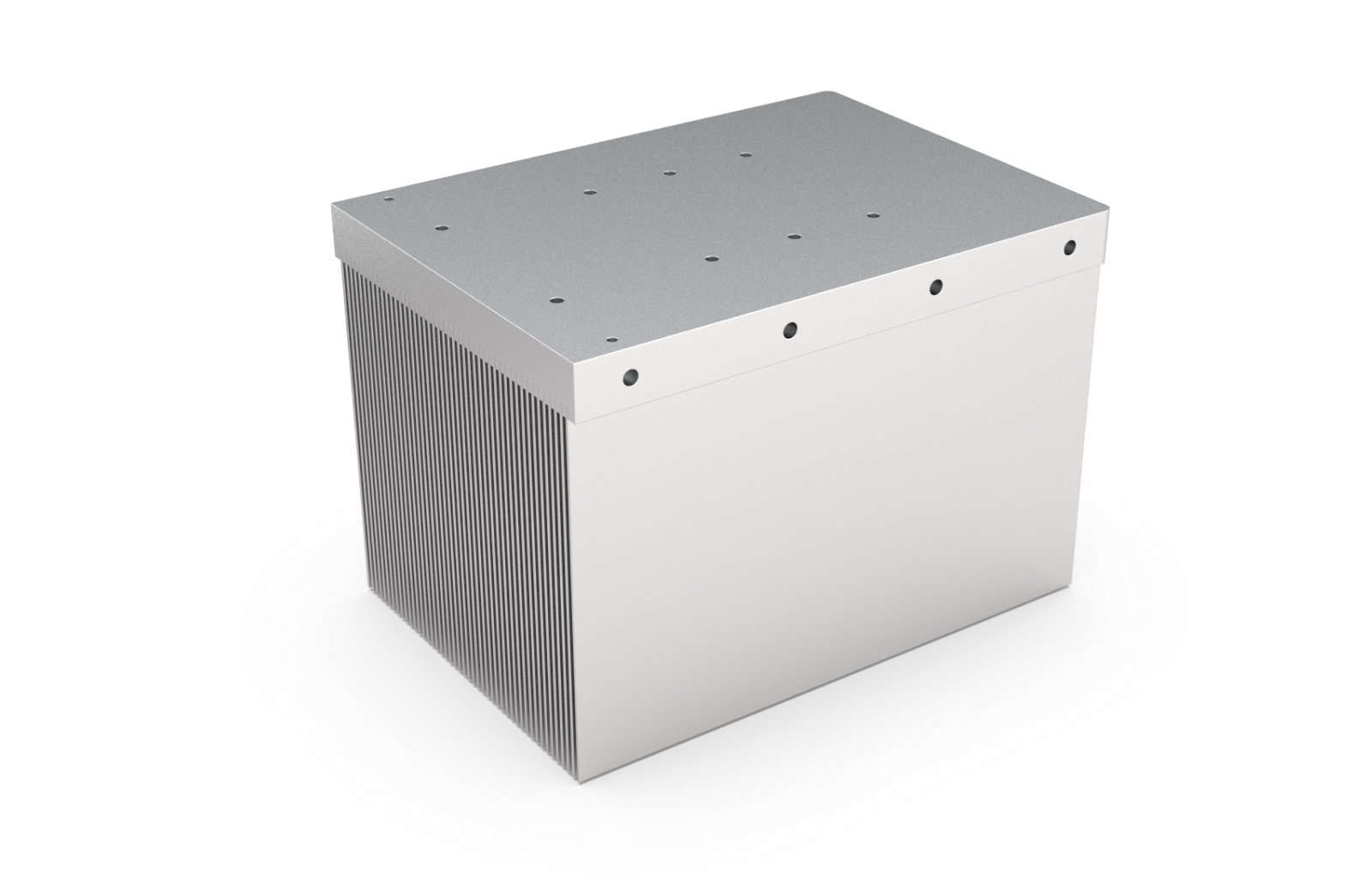

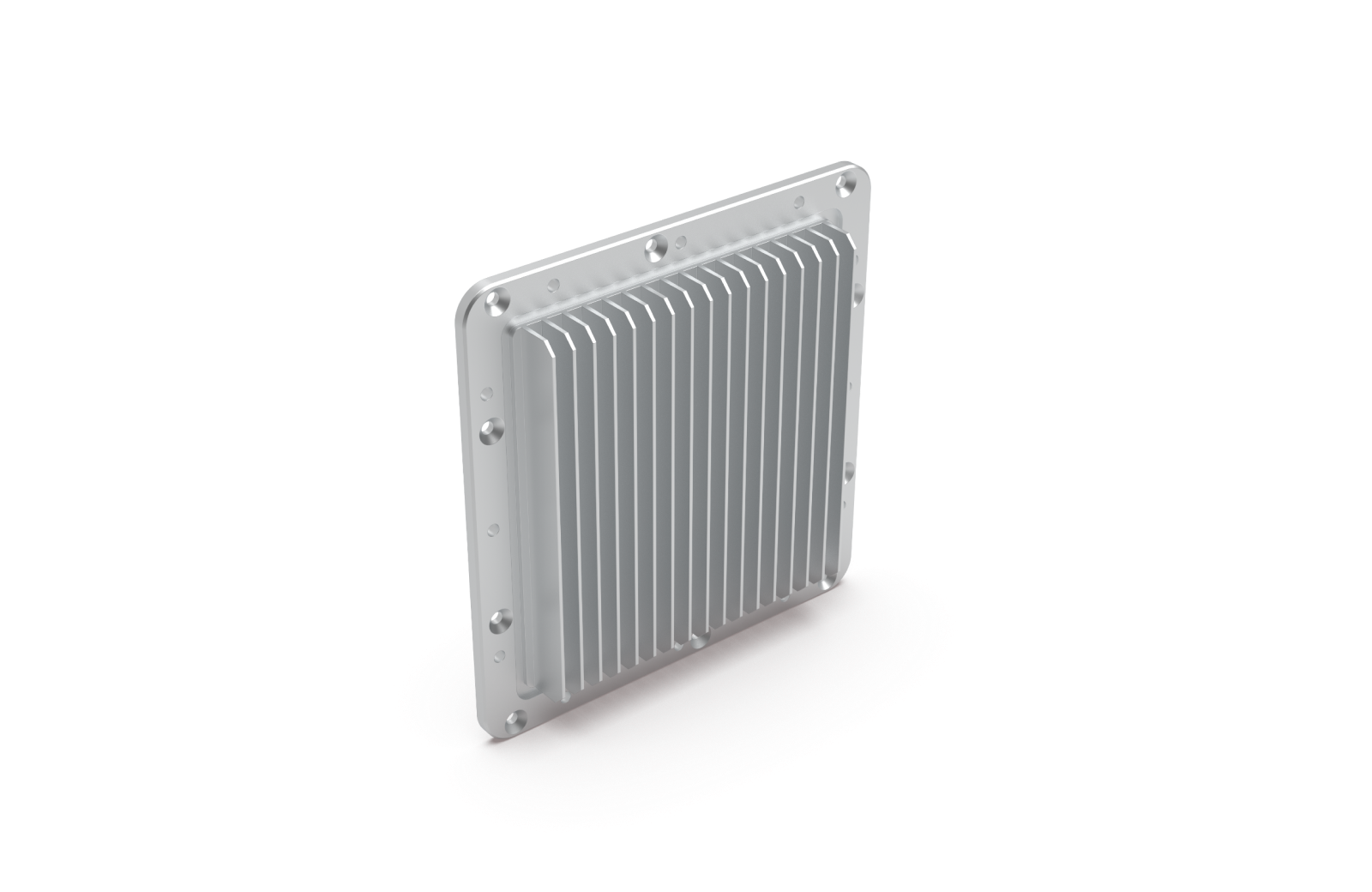

Bondfin heat sinks provide maximum cooling performance in minimal space thanks to densely packed fins – ideal for high thermal loads.

Contact usVirtually no limits for minimal spacing between fins

High fins achievable even with thin base plates

Significantly more flexible than conventional extruded heat sinks

Large surface area for efficient heat dissipation

Excellent thermal connection between fins and base

Suitable for bonded fin heat sinks of any size and demanding thermal management applications

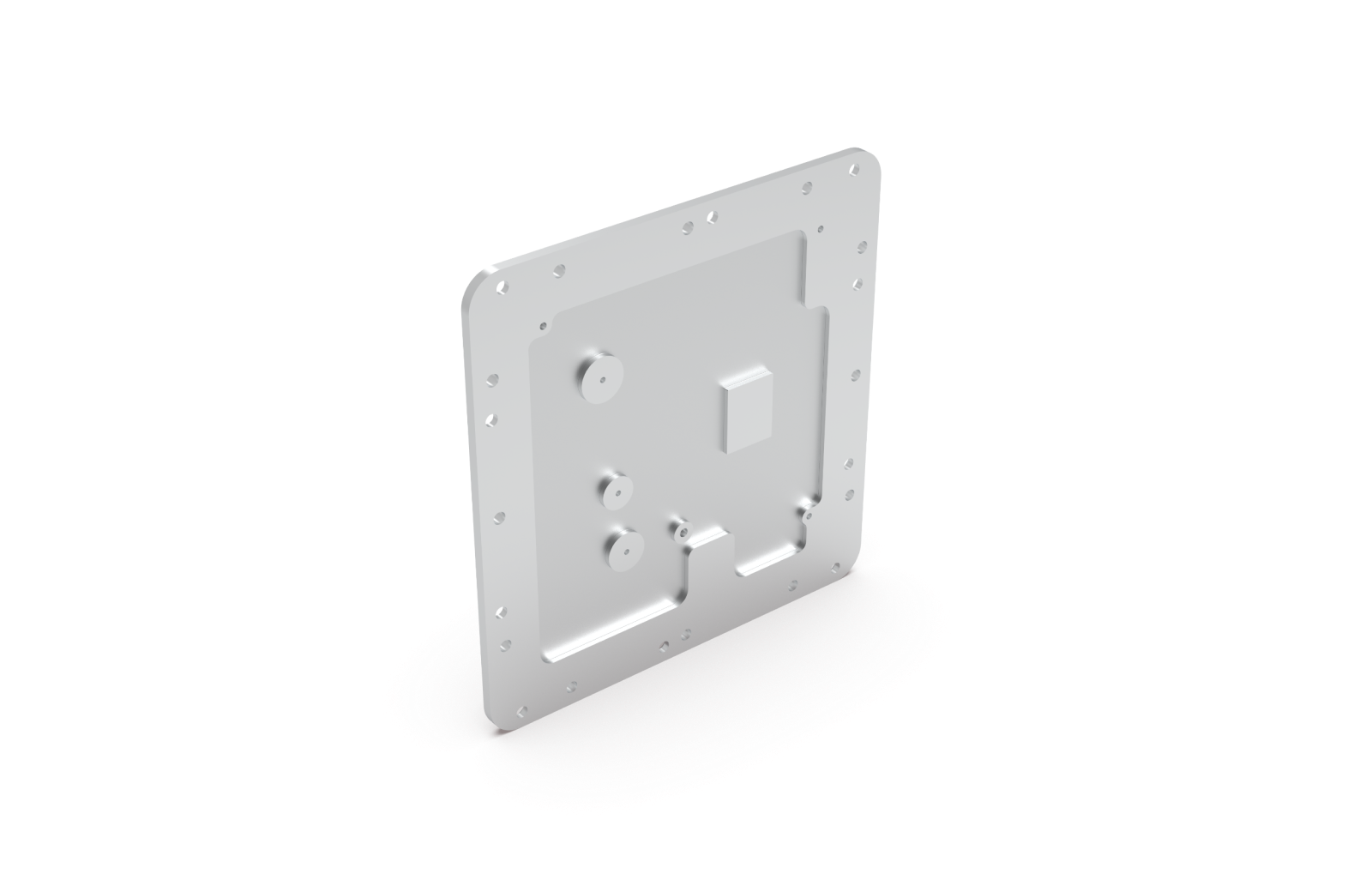

From machining to module assembly

Over 30 semi- and fully automated 3-, 4- and 5-axis CNC machining centers

In-house welding, soldering, and bonding technologies

Manufacture of complex heat sinks of any kind with short cycle and delivery times

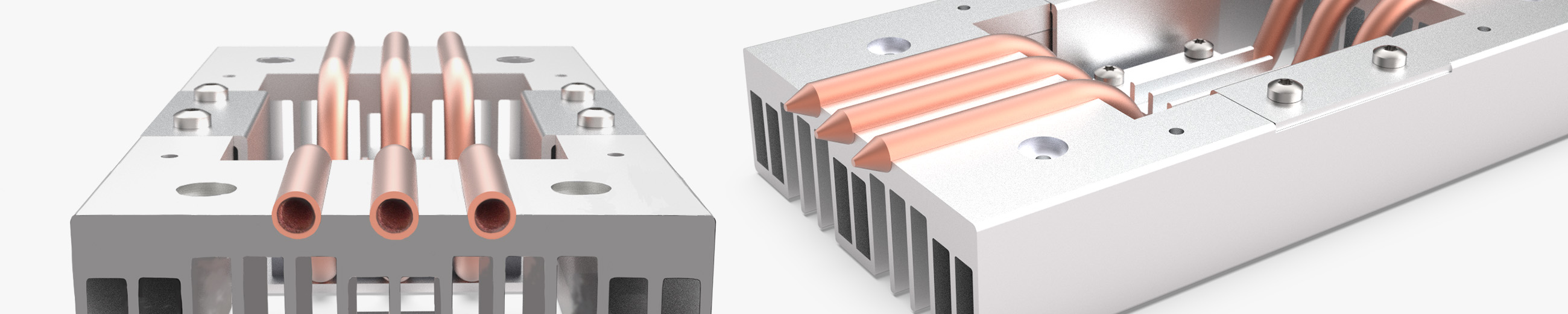

Pressed-in heat pipes efficiently transfer heat from the source to the fins. The fluid inside evaporates at hot spots, transports the heat via vapor, and condenses in cooler areas. This closed-loop process distributes heat evenly throughout the entire cooling structure – ideal for localized hotspots and high thermal loads.

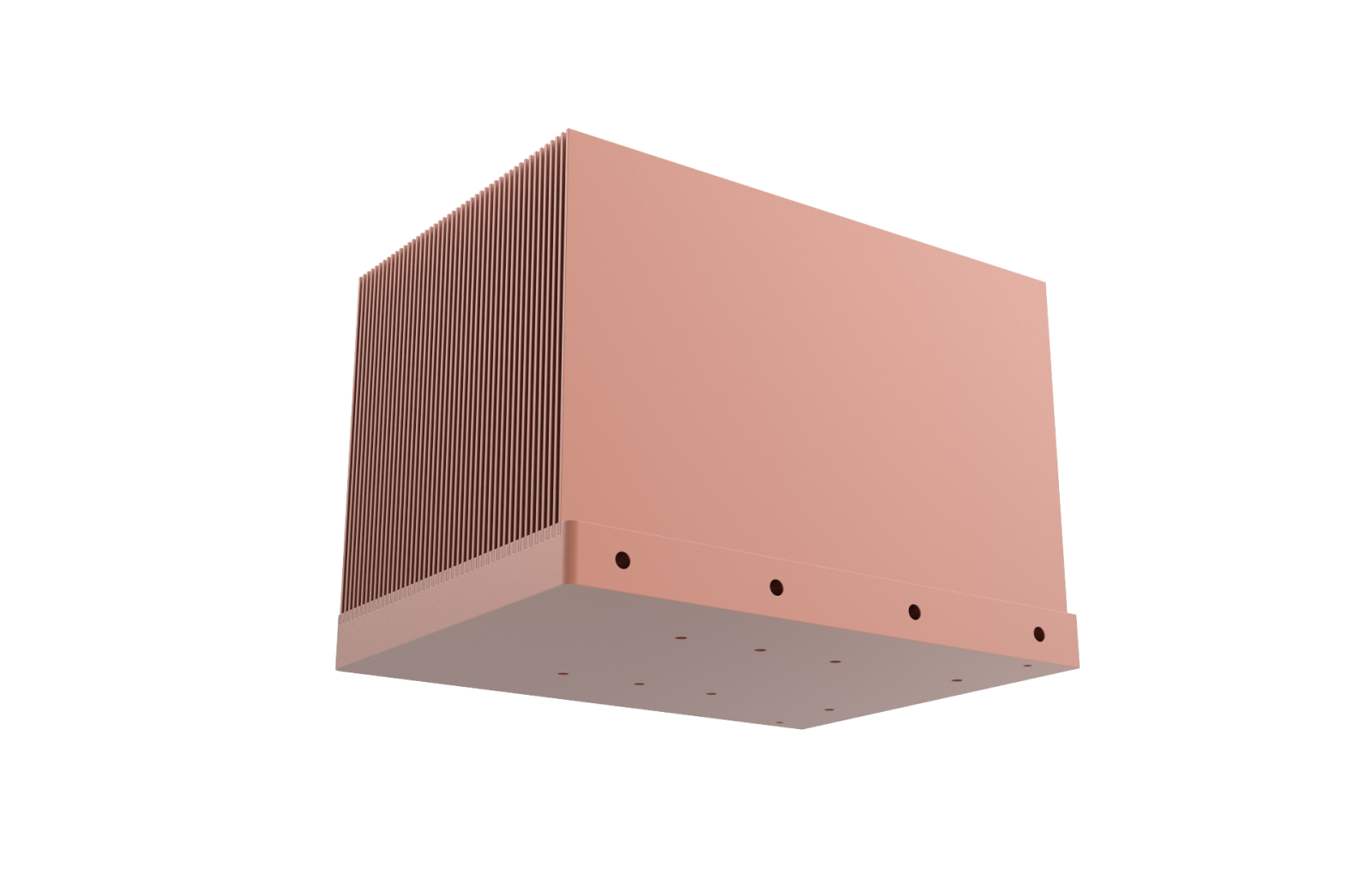

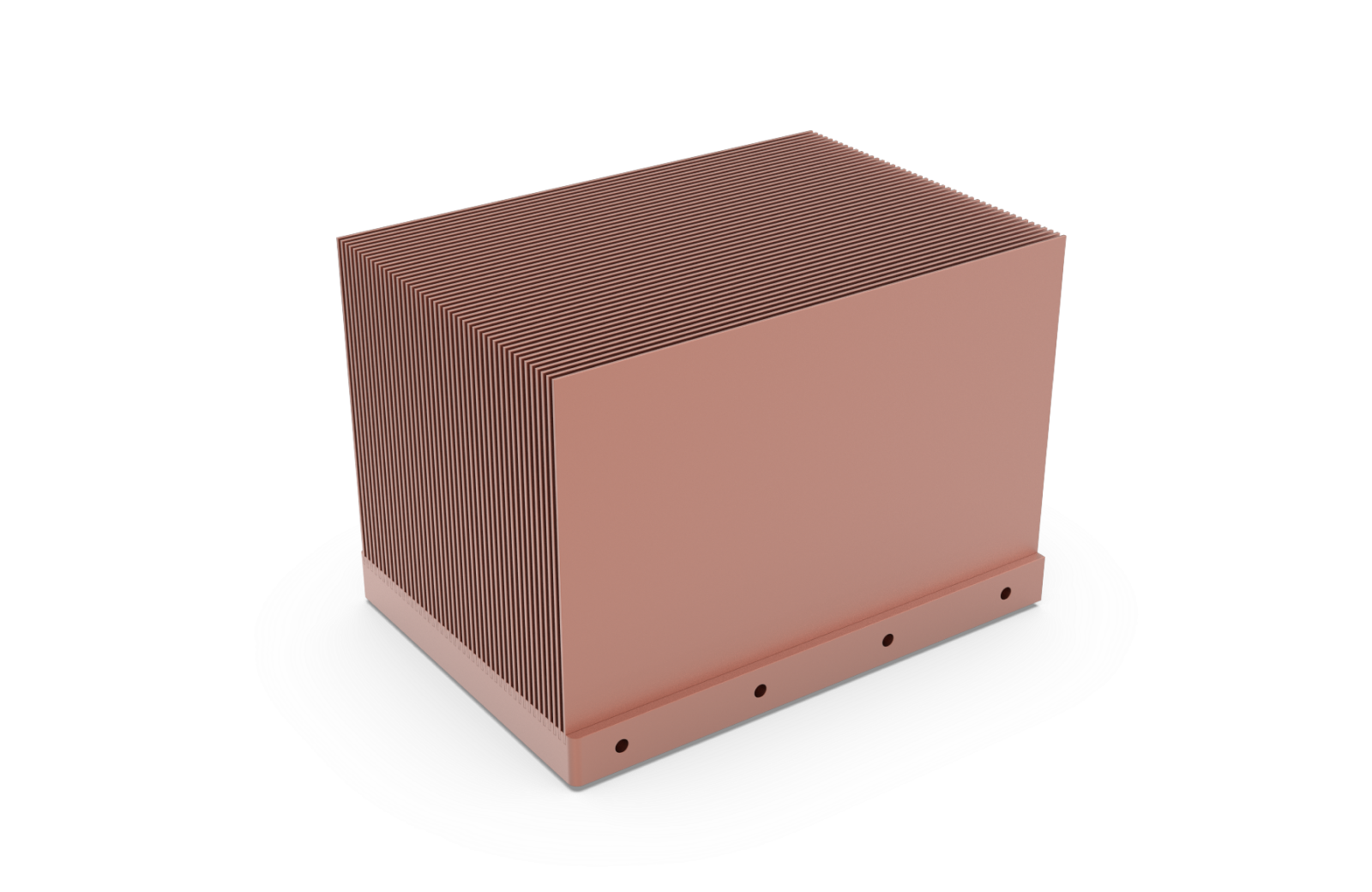

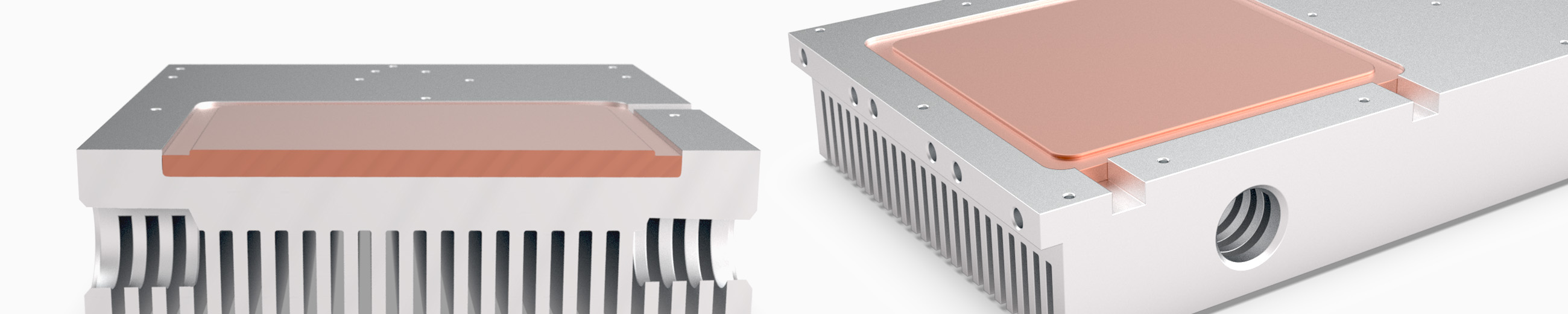

Copper inserts act as effective heat spreaders. With significantly higher thermal conductivity compared to aluminum, they ensure uniform temperature distribution – especially under heavily loaded components or media-carrying structures. This prevents local overheating and ensures stable electronic operation.

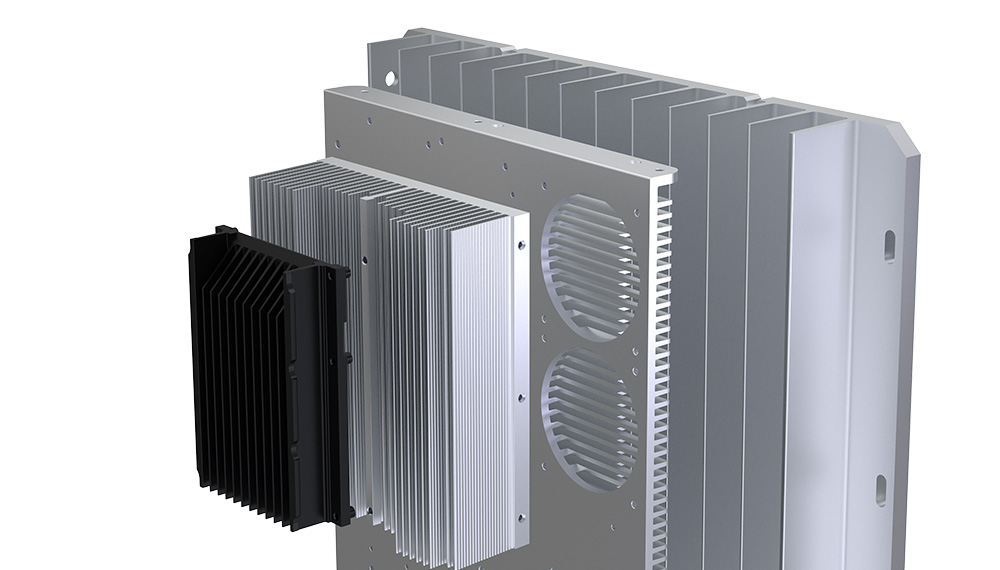

Bonded fin heat sinks consist of individually joined fins that are soldered, bonded, or welded to a base plate. This design allows for extremely fine fin spacing and a large surface area for efficient heat dissipation. Compared to extruded profiles, this technology enables much more compact and powerful heat sinks – ideal for applications with high heat density and limited installation space.

Learn more in a consultationLarge cooling surface for optimal heat dissipation

Customizable fin height and spacing

Versatile joining techniques (soldering, bonding, welding)

Compact design for limited space

High reliability and long service life of electronic components

Our engineering team is happy to advise you on selecting and developing your ideal heat sink – individually, precisely, and quickly.

A bonded fin heat sink is a component for efficient heat dissipation. Its thin, fin-like structures provide a large surface area, allowing heat from electronic components to be effectively transferred to the air.

Bonded fin heat sinks are made of individual fins permanently connected to a base – for example, through soldering, welding, or bonding. This design allows very thin bases and narrow fin spacing for particularly high cooling performance.

Bonded fin heat sinks feature a large surface area, efficient heat dissipation, compact design, flexible configuration, and longer component lifespan.

Additional technologies such as pressed-in heat pipes or copper inserts as heat spreaders help distribute heat faster and more evenly. This enables better cooling of local hotspots and enhances overall performance.

Bondfin is a COOLTEC-developed method for manufacturing bonded fin heat sinks. It enables exceptional fin-to-base ratios, minimal fin spacing, and high fins with thin bases – perfect for high cooling demands and limited installation space.