Air Heat Sinks for Efficient Heat Dissipation

Cooling issues are costing you performance and process reliability? Together, we’ll develop a solution that truly works for your system.

Contact us nowDesigns and Applications of Our Air Coolers

Whether for standard applications or specific requirements – we offer the right air heat sink for every situation. With a wide range of designs and the option for custom manufacturing, we support your project from concept to implementation.

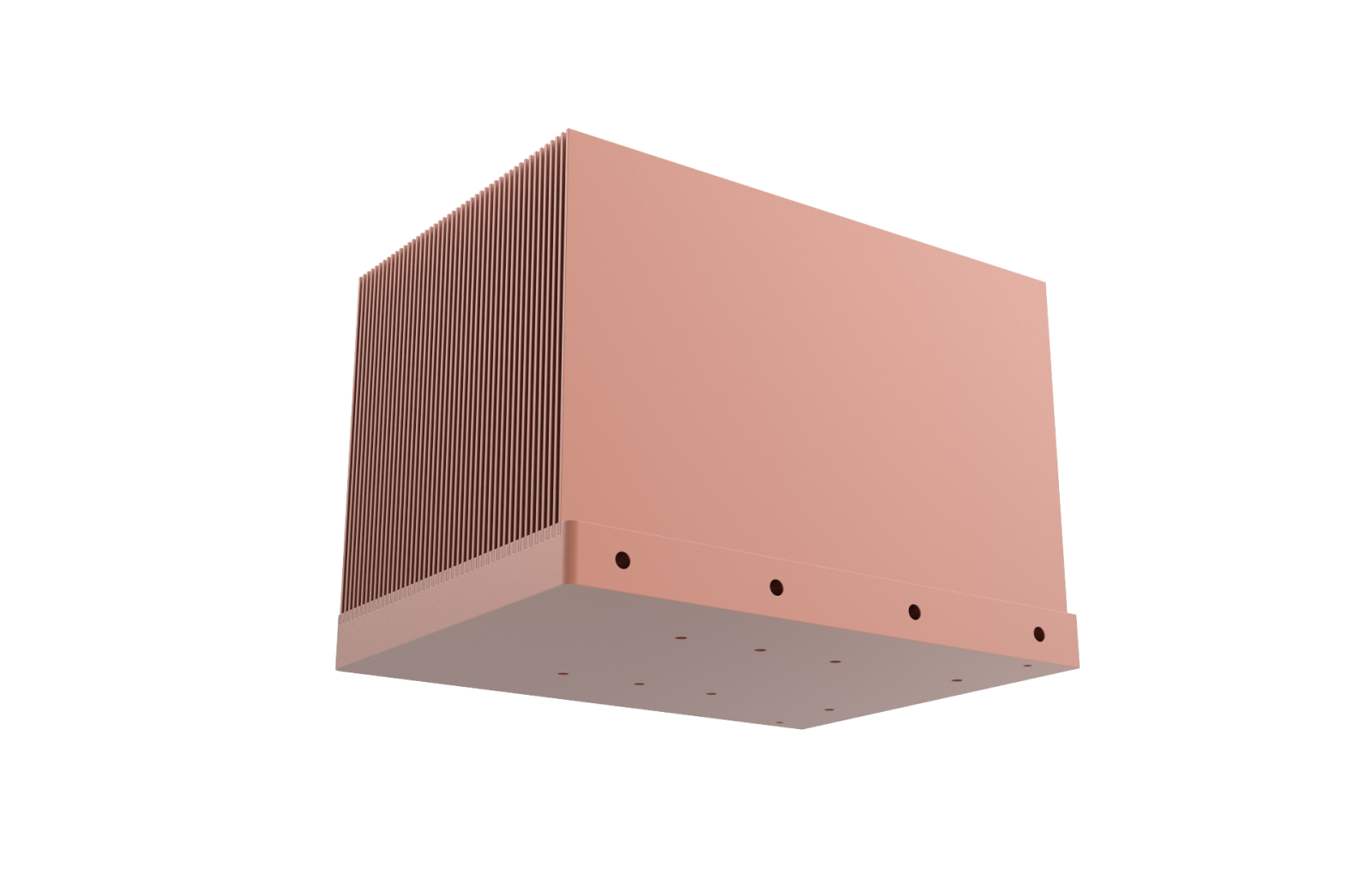

Extruded Profile Heat Sinks | Extrufin

Extruded fin structure for efficient passive cooling.Your benefits: High efficiency, flexibility in profile selection

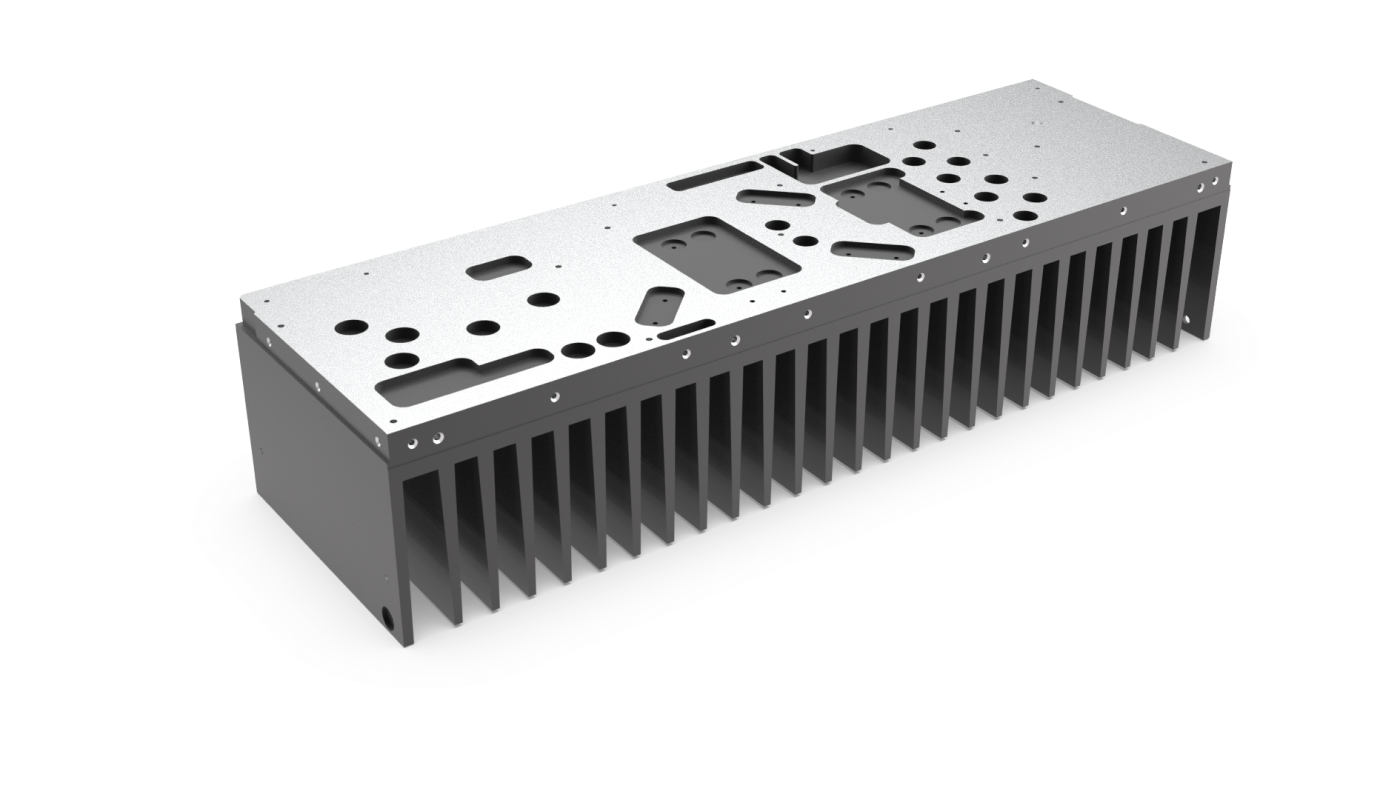

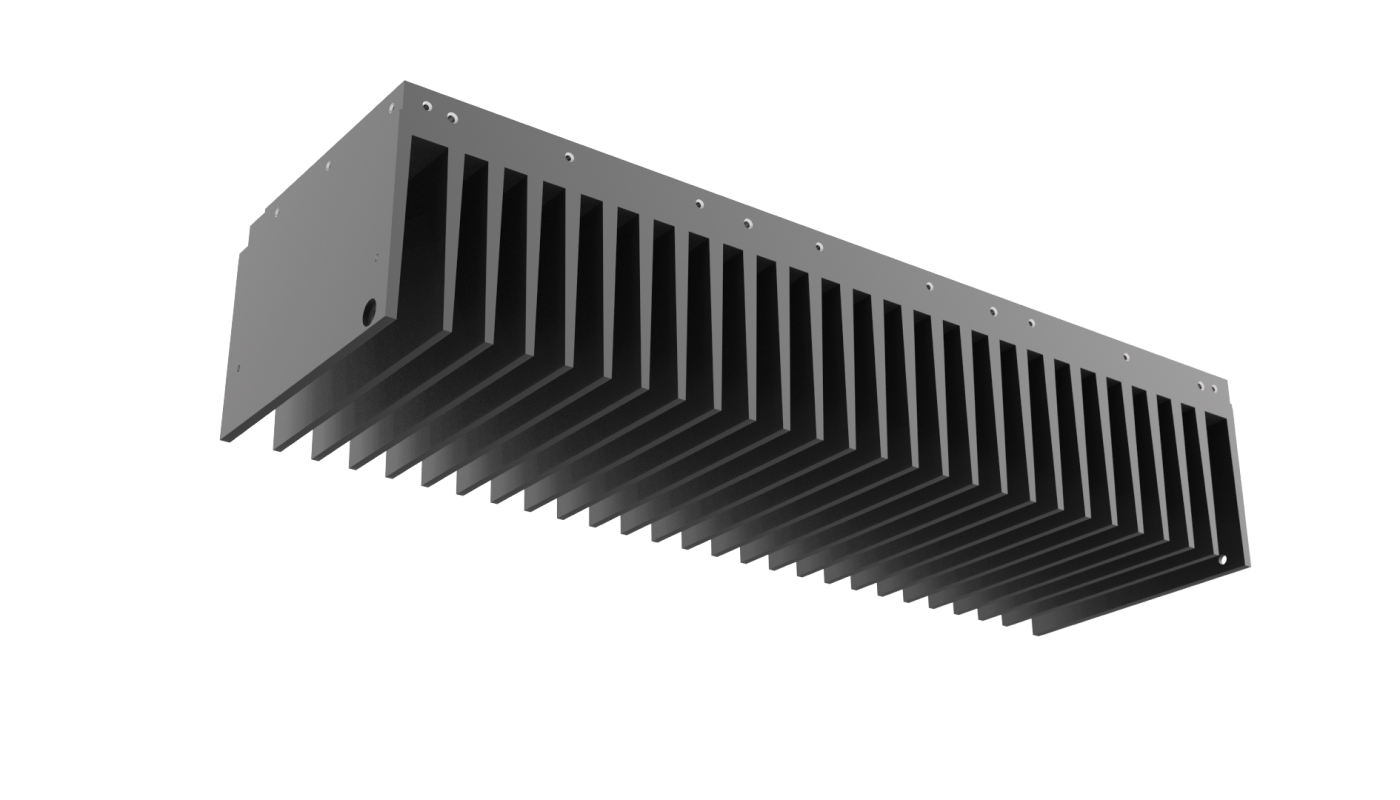

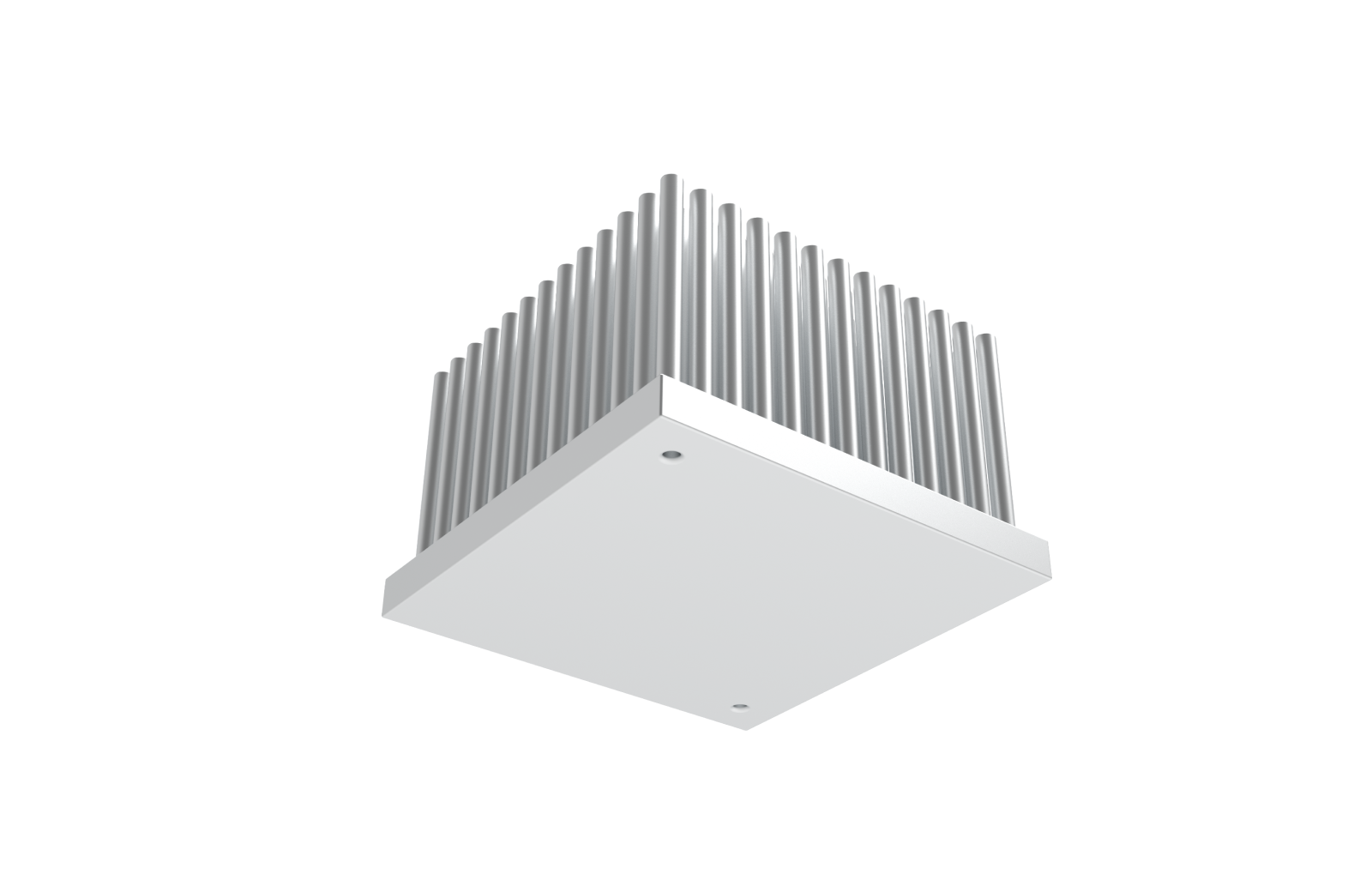

Side-Pressed Heat Sink | Pressfin

Side-pressed cooling fins for maximum cooling surface in minimal space.Your benefits: Robust construction, flexible integration

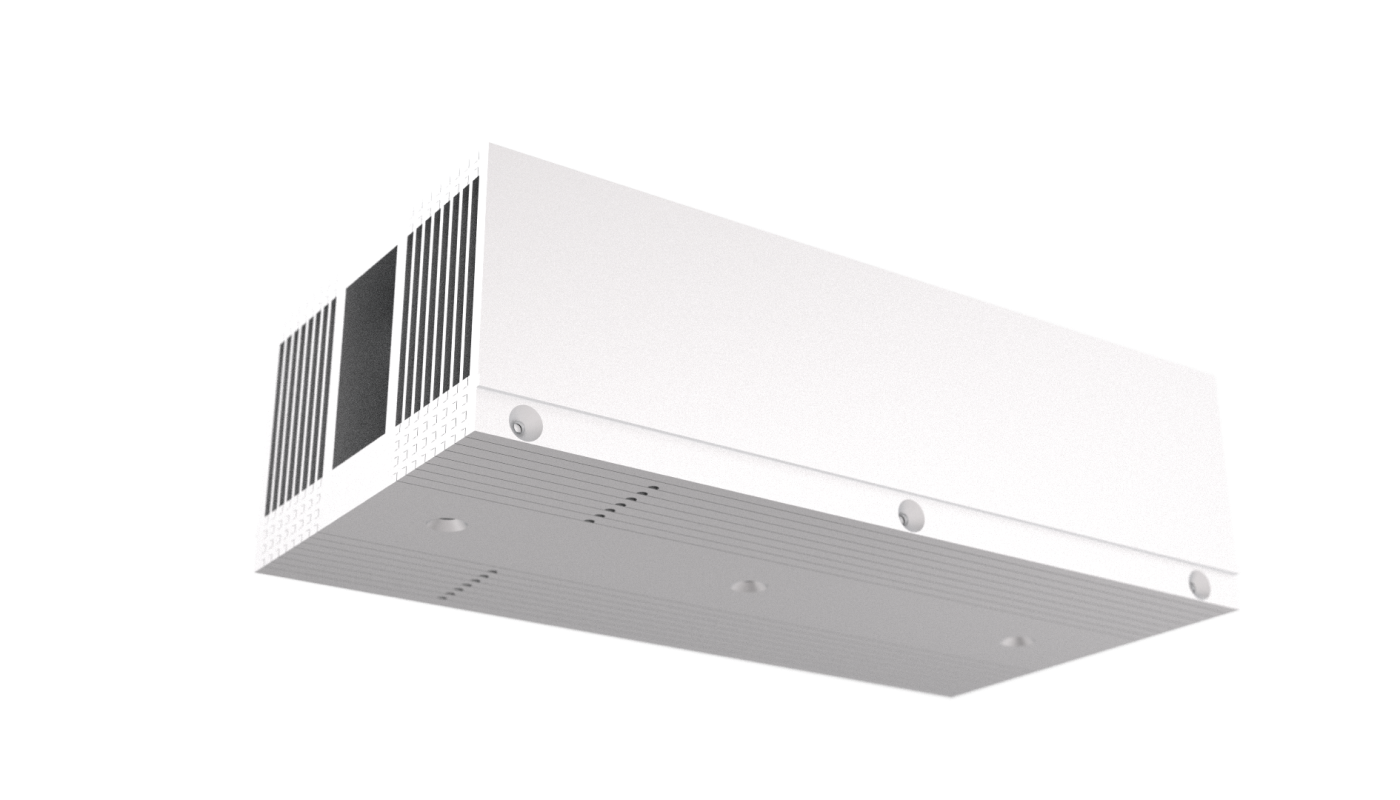

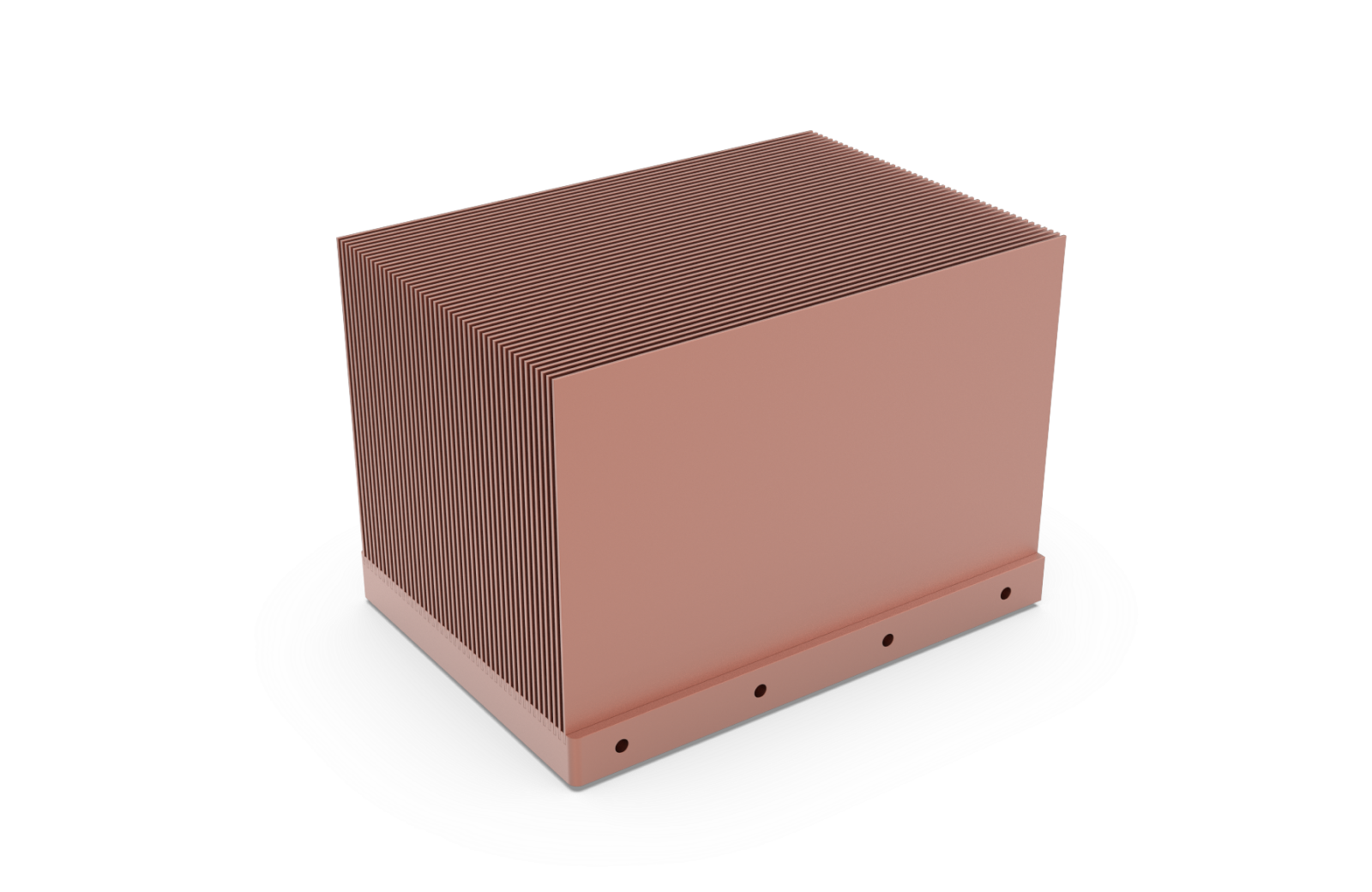

Bonded Fin Heat Sink | Bondfin

Bonded aluminum fins for excellent thermal performance.Your benefits: Compact design, high heat transfer

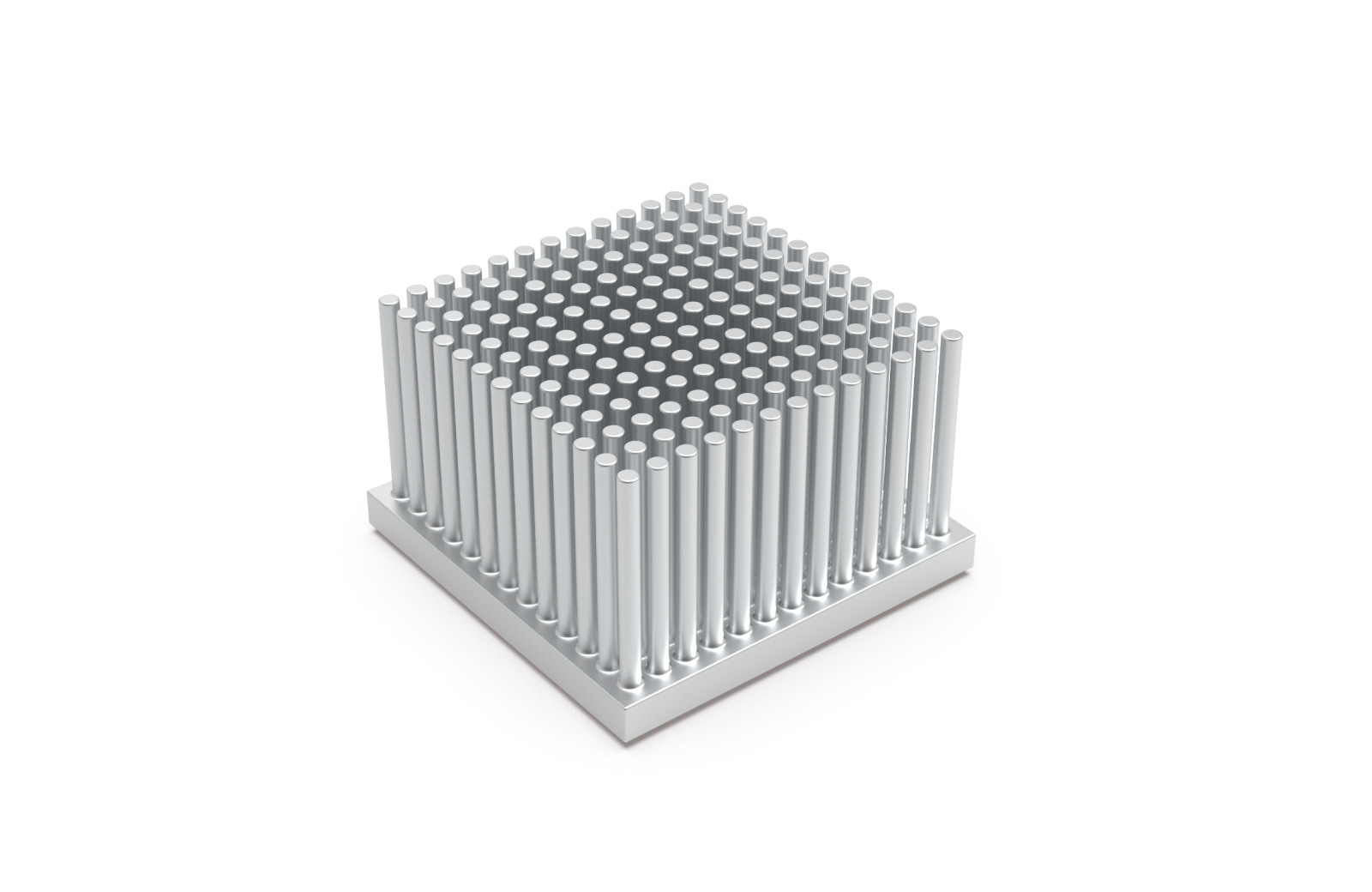

Extruded Pin-Fin Heat Sink | Pinfin

Three-dimensional pin design for maximum surface area and air contact.Your benefits: Very high cooling performance, ideal for natural convection

These customers rely on COOLTEC's cooling solutions

Technology & Function of Air Heat Sinks

Air heat sinks – also known as finned coolers or profile heat sinks – ensure efficient heat dissipation through natural or forced convection. They are mainly used for passive cooling of power electronics. Thanks to their enlarged surface area – usually in the form of fins or pins – they maximize air contact and enable reliable temperature regulation. The larger the surface area, the more effective the heat dissipation. While conventional high-performance cooling profiles often entail high tooling costs and minimum quantities, our cooling systems offer flexible profile design with cost-effective manufacturing – ideal for medium batch sizes and prototypes.

Depending on the application and requirements, passive or active cooling solutions are used. Passive cooling is particularly efficient with low power dissipation and reliable air circulation. Also Liquid cooling can be an alternative for high thermal loads.

Advantages of our Aluminum Air Heat Sinks

Aluminum is the ideal material for air heat sinks. COOLTEC aluminum air heat sinks offer improved heat dissipation thanks to anodized surface finishing and additional benefits such as:

High thermal conductivity: Perfect for efficient heat dissipation.

Lightweight and corrosion-resistant: For long-lasting and reliable cooling.

Good formability: Enables customized solutions for any application.

Sustainability & Materials in Cooling

Our air heat sinks are made from high-quality aluminum, which makes a significant contribution to sustainable electronics cooling not only due to its excellent thermal conductivity, but also due to its recyclability. Aluminum can be 100% recycled, significantly reducing the ecological footprint of our heat sinks.

We rely on environmentally friendly manufacturing processes, optimizing material usage and maximizing energy efficiency during production. In this way, we make a direct contribution to resource-saving thermal management.

Sustainability at COOLTECCalculate & Design Heat Sinks

To calculate the correct heat sink size, various factors must be considered, including:

- Power dissipation of the component

- Ambient temperature

- Airflow (natural or forced)

- Mounting type and thermal resistance

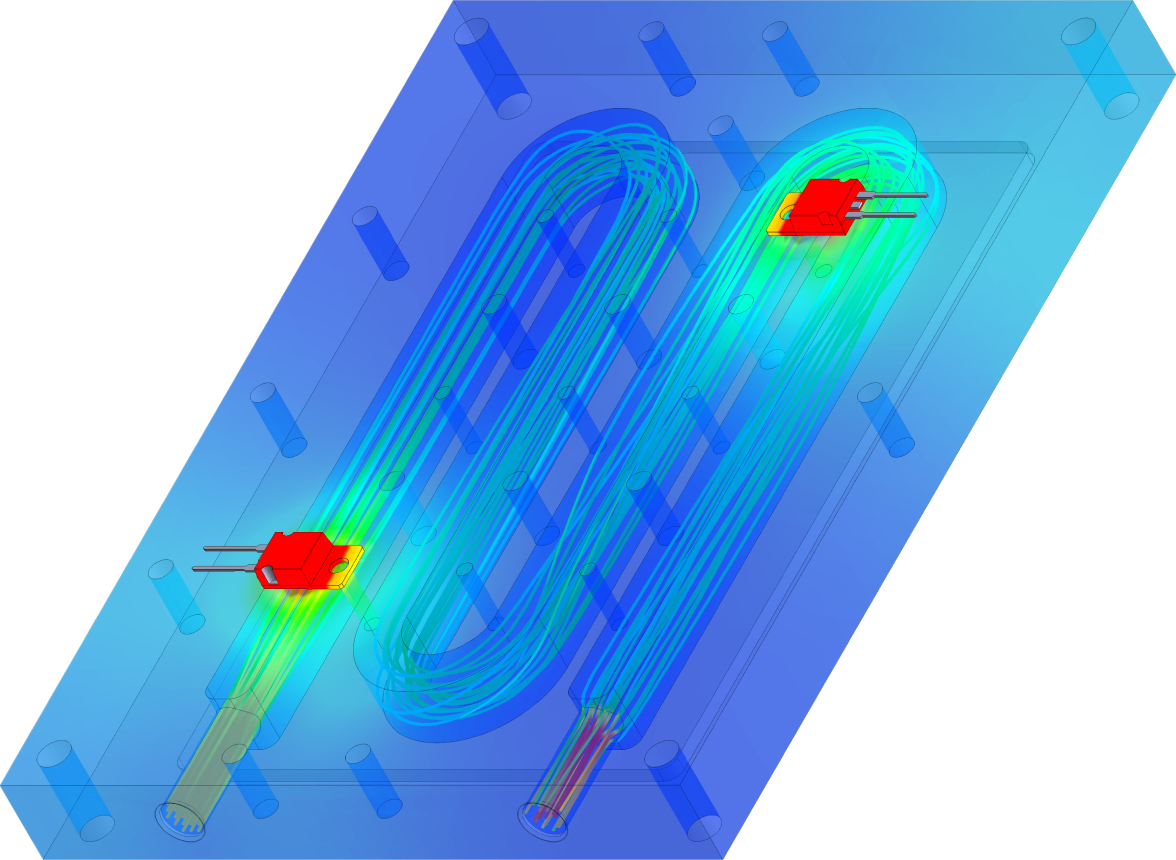

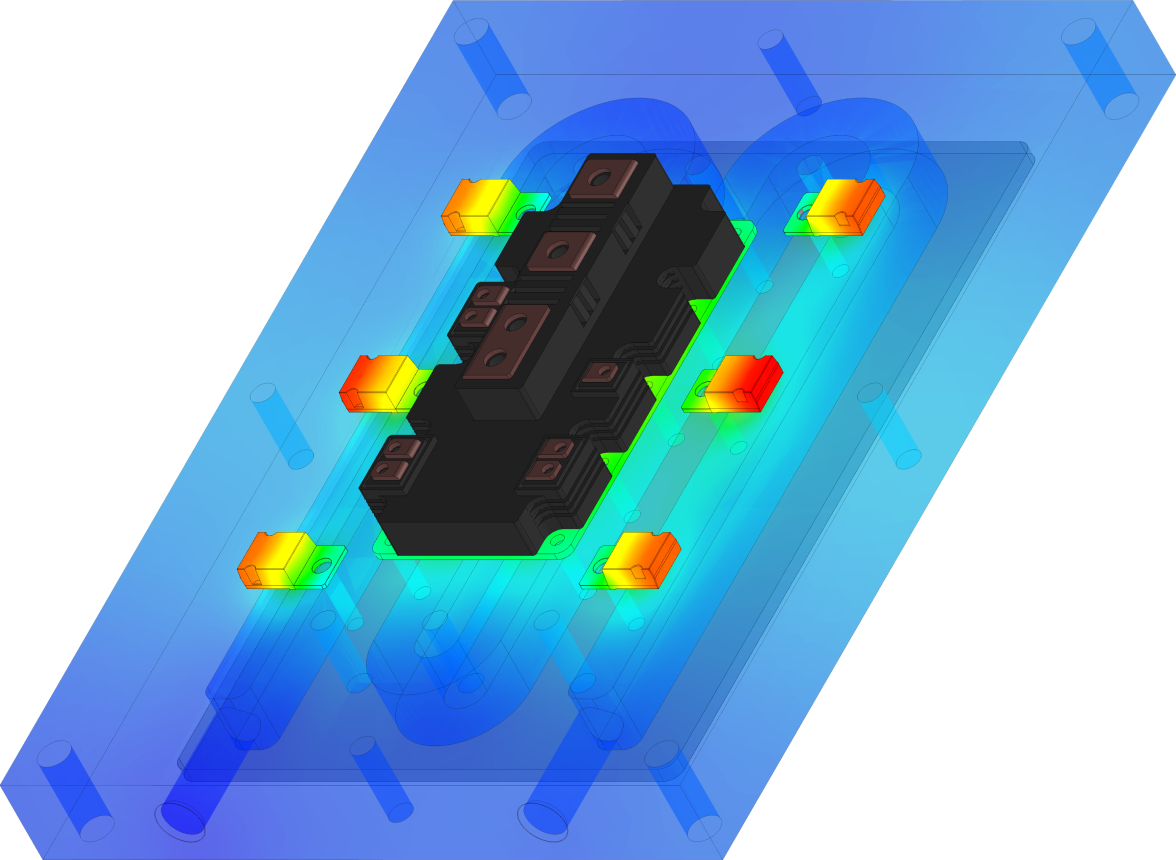

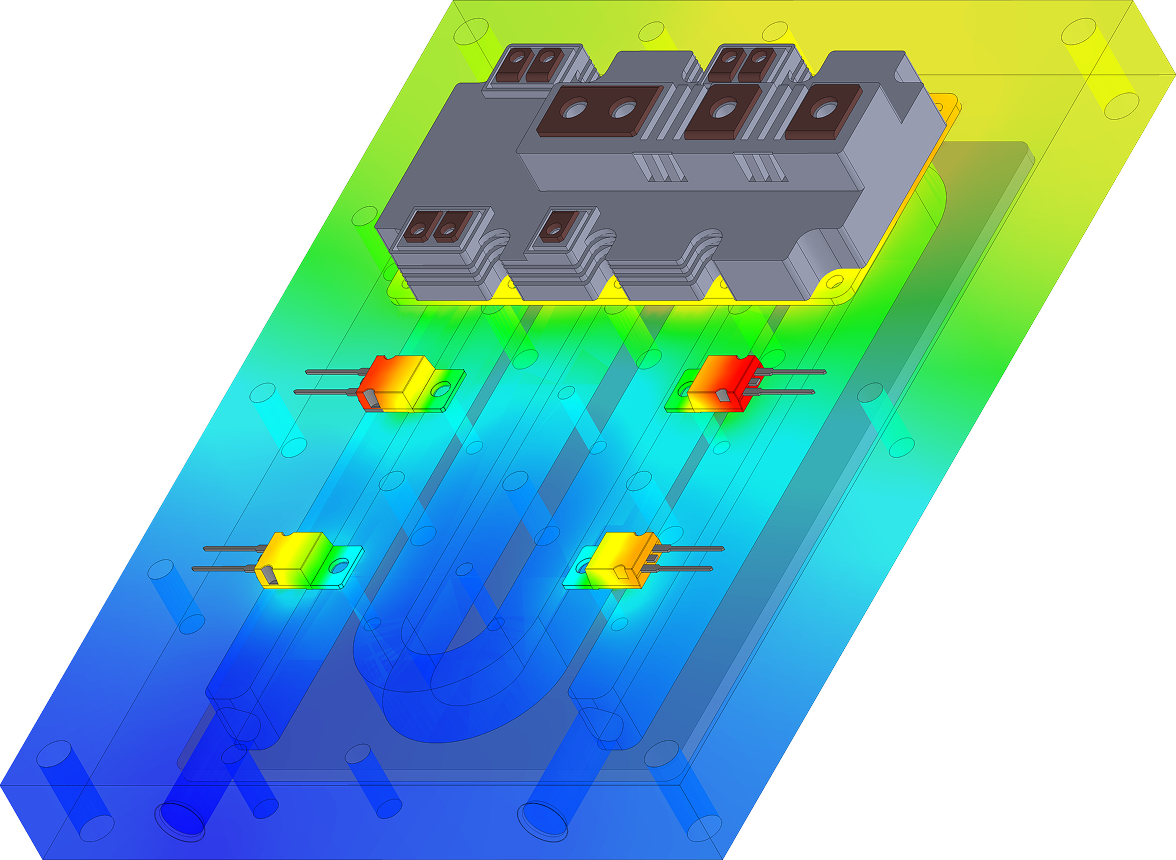

Our thermal simulation tools enable precise calculation of the optimal heat sink size and shape to ensure efficient cooling without oversizing or thermal risks.

Standard or customized – Find the perfect cooling solution with us!

Choose from over 500 proven profiles in our product database or develop a custom solution together with us. Contact us now!

Frequently Asked Questions

An air heat sink is a component that dissipates heat from electronic components into the surrounding air, usually made of aluminum.

When power losses are low and natural air circulation is possible, such as with LED drivers or small power components.

Use our thermal simulation, CAD data, or get direct advice. Alternatively, you can choose from over 500 standard profiles: View standard profiles.

Yes, our aluminum profiles are largely recyclable – we are happy to advise you on sustainable solutions.