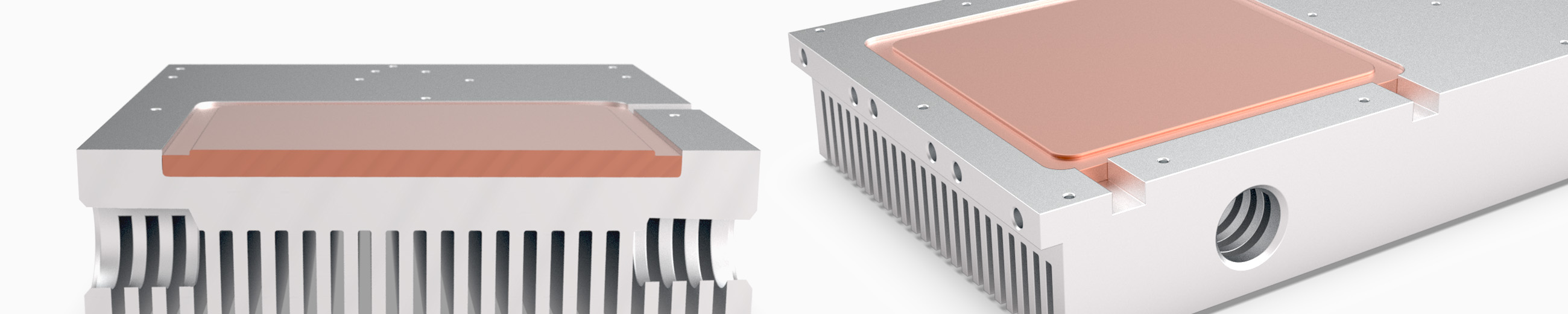

Bonded Fin Heat Sinks

Discover how bonded fin heat sinks meet extreme performance demands – with maximum surface area and minimal space requirements.

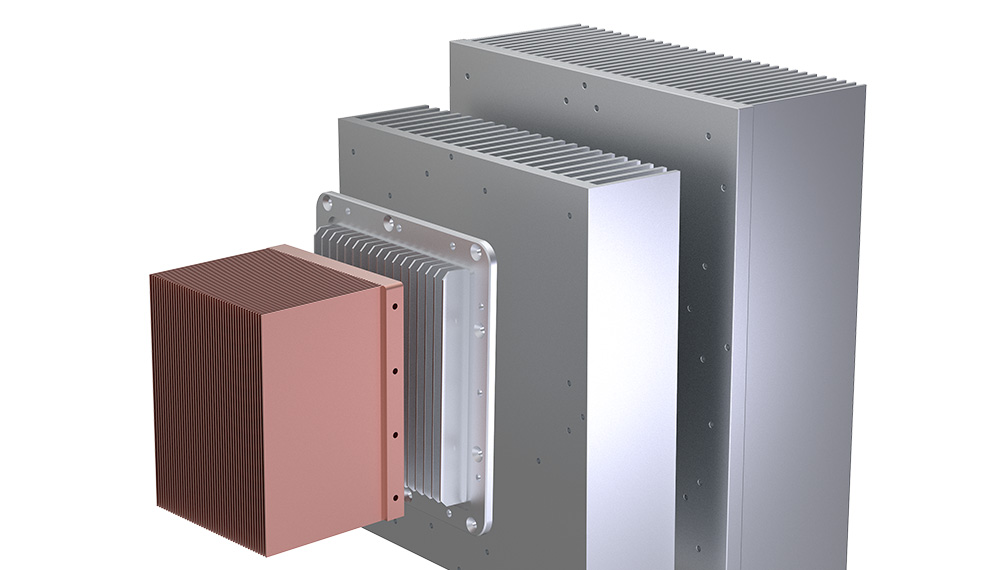

Our Pressfin heat sinks with side-pressed aluminum fins are ideal for applications with high heat density and limited installation space.

Get in touchAdjustable width across different product families to meet individual requirements

Use of individual extruded profiles made from EN AW 6060 or EN AW 6063

Cooling and mounting of components on both sides possible

Precise implementation of complex modifications such as reduced base thicknesses, targeted fin clearances, and custom milling geometries

Double-sided drilling and threading possible

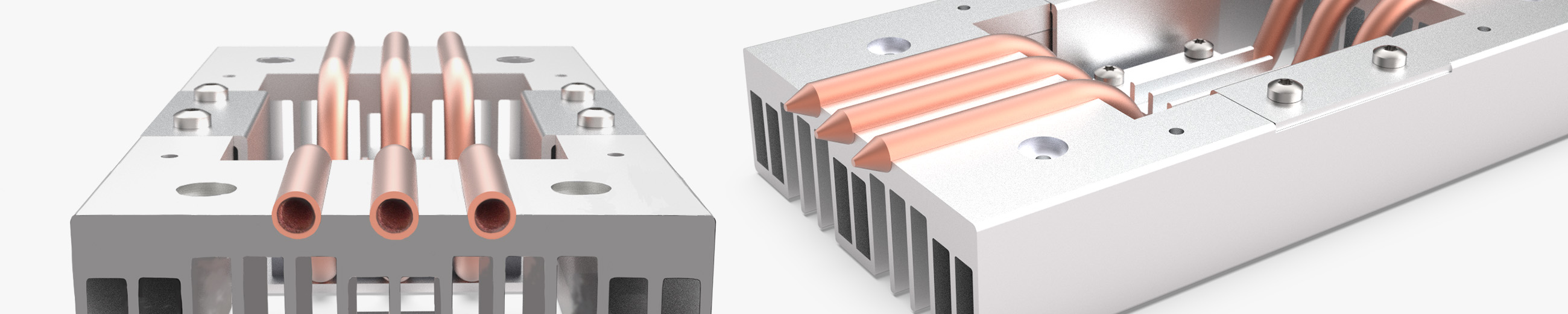

Heat pipes transfer heat extremely efficiently from the heat source to the cooling fins. Their closed circuit allows the internal fluid to evaporate when heated, transport the heat, and condense in cooler areas. This makes them ideal for localized hotspots and high power densities.

Copper has a significantly higher thermal conductivity than aluminum. Embedded copper inserts ensure uniform and targeted heat distribution, for example beneath fluid channels or heavily loaded components. This results in stable operating temperatures and extends the lifespan of electronics.

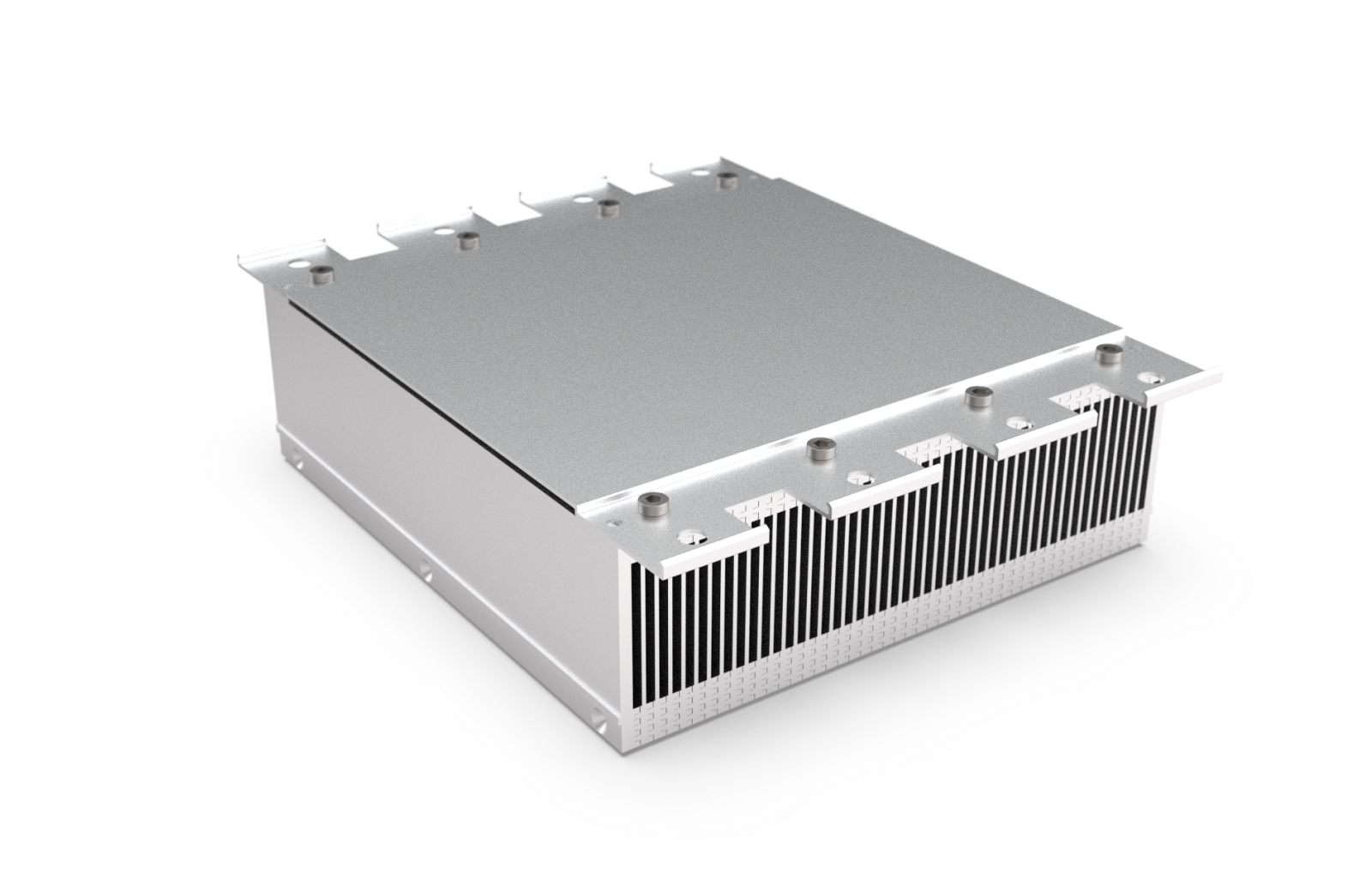

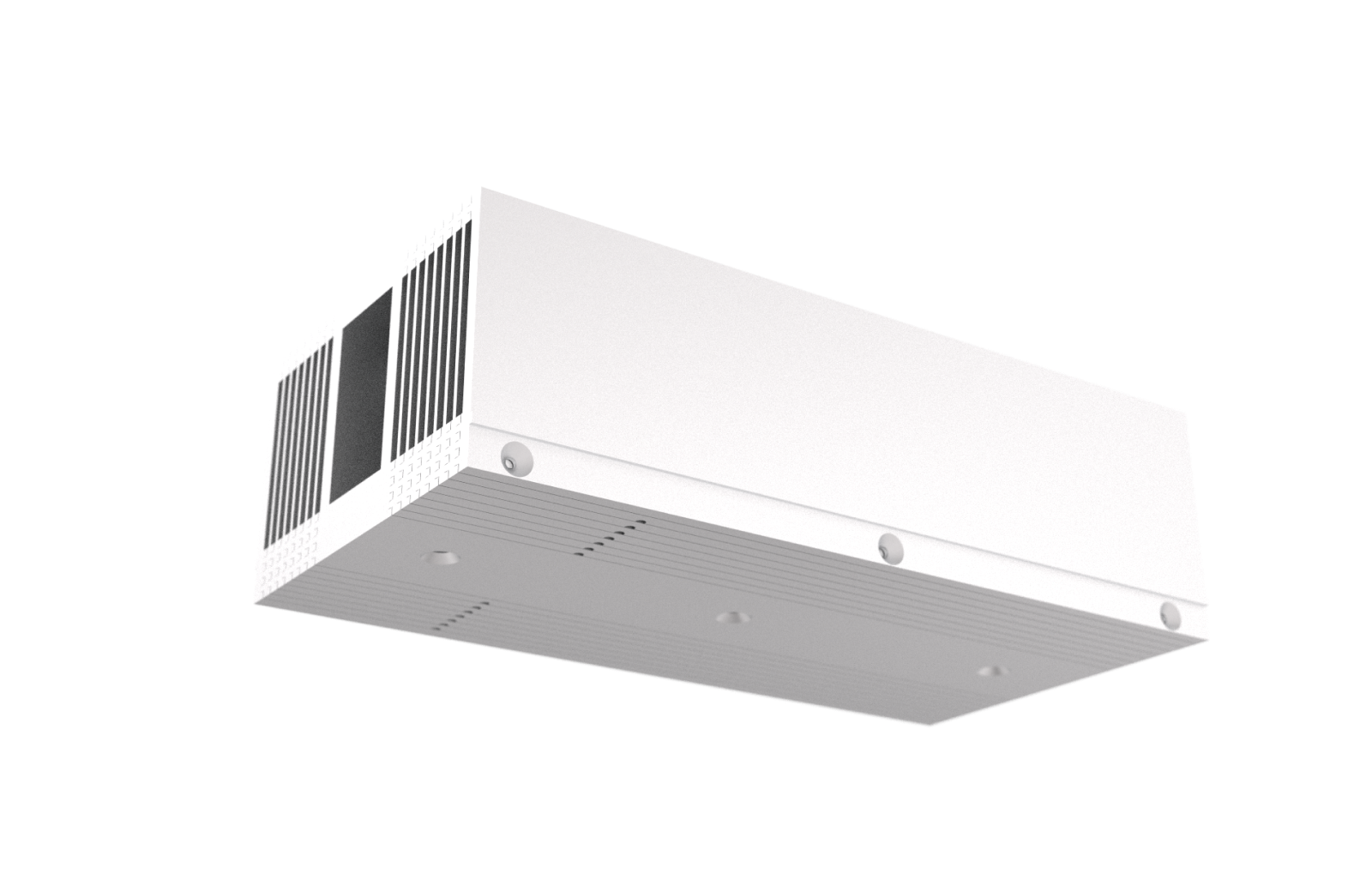

Side-pressed fin heat sinks are a special type of air-cooled heat sink distinguished by their unique construction. The fin-like plates are pressed in from the sides, creating a particularly stable structure.

This design significantly increases the cooling surface area, optimizing heat dissipation through convection and improving overall cooling performance. The symmetrical design also enables double-sided component mounting and cooling.

Learn more in a conversationMaximum cooling performance in minimal space

Variable number and spacing of fins – individually adjustable

Double-sided component mounting and cooling possible

Flexible configuration for thermal and mechanical requirements

High production quality – Made in Germany

Our experienced team supports you in selecting and customizing your perfect heat sink – fast, tailored, and professional. Let’s find the best solution together!

Side-pressed finned heat sinks consist of individual aluminum fins that are pressed laterally into a base plate. This design maximizes the surface area for heat dissipation and enables highly effective air cooling in a compact space. The solid press-fit ensures high thermal conductivity between the fins and the base.

Finned heat sinks provide greater design flexibility in terms of fin number and spacing, allow components to be mounted on both sides, and are ideal for applications with limited space. Thanks to their modular design, thermal and mechanical requirements can be implemented flexibly - ideal for demanding electronic applications.

Finned heat sinks are mainly used in power electronics, mechanical engineering, LED technology, and renewable energy systems. They are particularly suitable where a compact design with high cooling performance is required - for example, in inverters, power supplies, or control units.

Yes - COOLTEC heat sinks can be flexibly configured in width, fin number, and spacing. This allows the cooling performance to be precisely adapted to your application's thermal requirements. Custom geometries and machining are also possible.

Our Pressfin heat sinks are made from aluminum alloys such as EN AW 6060 and 6063. For optimal performance and protection, we offer various surface treatments - for example, anodizing, powder coating, or chromate-free passivation. These increase corrosion resistance and improve heat dissipation.